Optical element of a laser material machining tool, laser machining head having an optical element, and method for operating a laser machining tool

A laser processing head and optical element technology, applied in the direction of optical elements, optics, manufacturing tools, etc., can solve the problems of optical element pollution, aging, wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

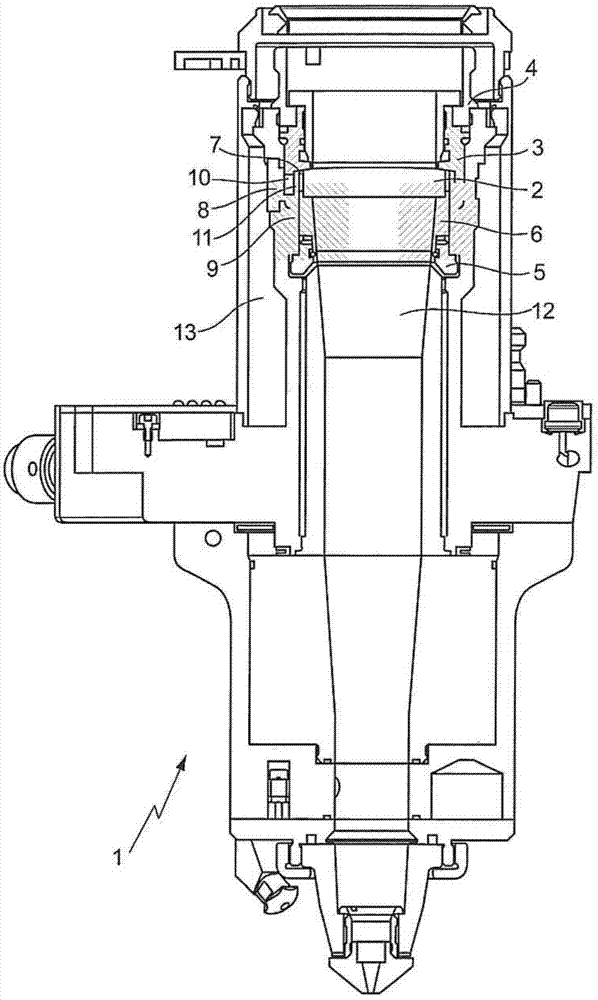

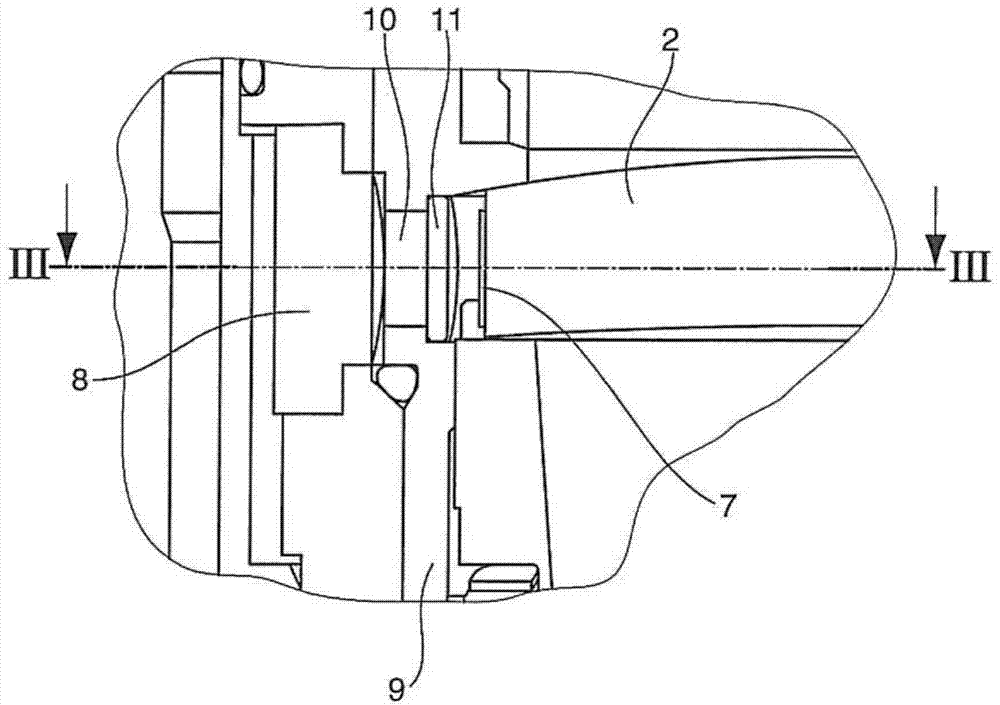

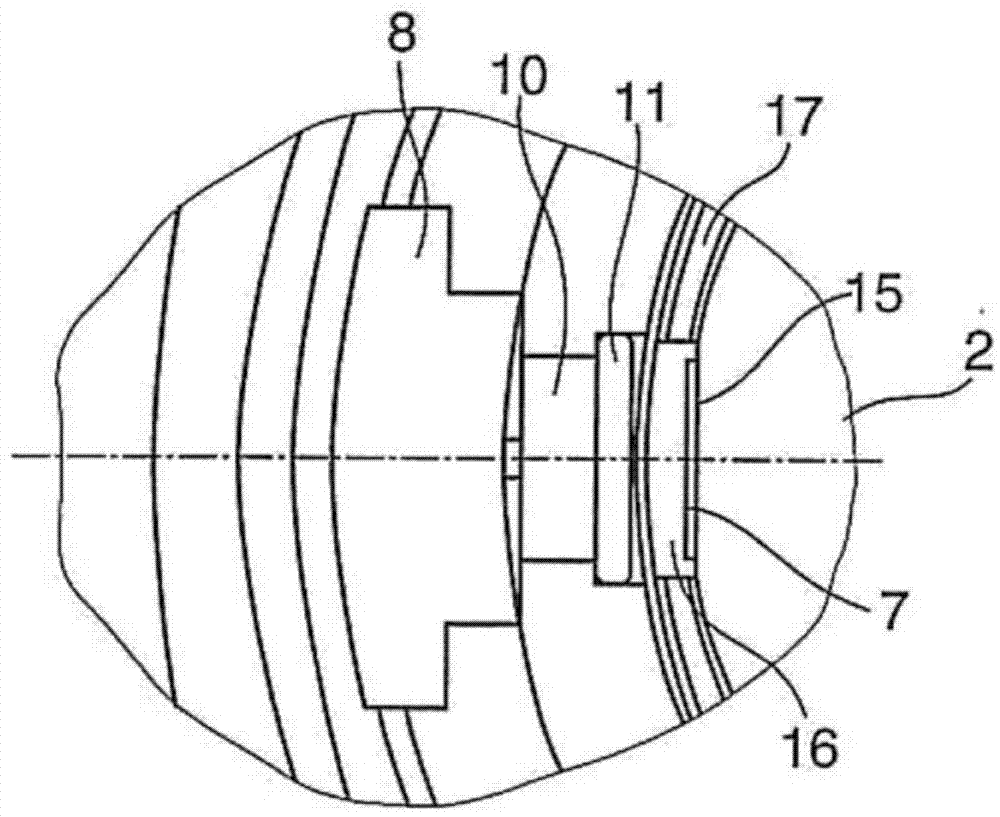

[0040] figure 1 A longitudinal sectional view of a laser processing head 1 designed as a laser cutting head of a laser material processing machine is shown. The laser processing head 1 has an optical element 2 configured as a lens. The optical element is arranged in a lens barrel 3 , wherein the lens barrel 3 is replaceable, in particular removable from the laser processing head 1 . A threaded ring 4 is shown at the upper end of the lens barrel 3 , which holds the lens barrel in the laser processing head 1 . The threaded ring 5 holds the optical element 2 in the lens barrel 3 and thus in the laser processing head 1 through a spacer 6 .

[0041] Arranged on the optical element 2 is a transponder 7 in the form of a radio frequency identification tag (RFID tag). The transponder is opposite the reading and / or writing device 8 . Information from the transponder 7 can be read out by means of the reading and / or writing device 8 and information can also be written into the transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com