Lithium-ion secondary battery

A secondary battery and lithium-ion technology, applied in secondary batteries, secondary battery manufacturing, lithium storage batteries, etc., can solve problems such as tank rupture, voltage rise, and pressure rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach ]

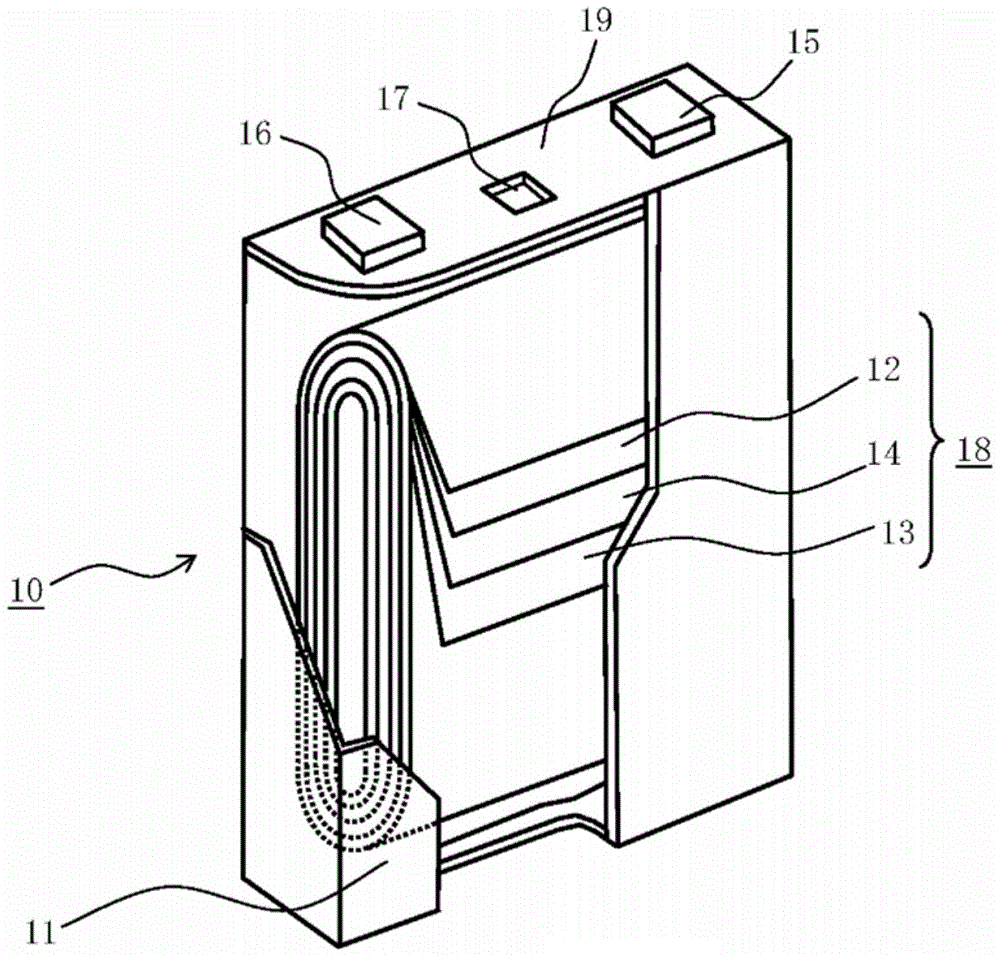

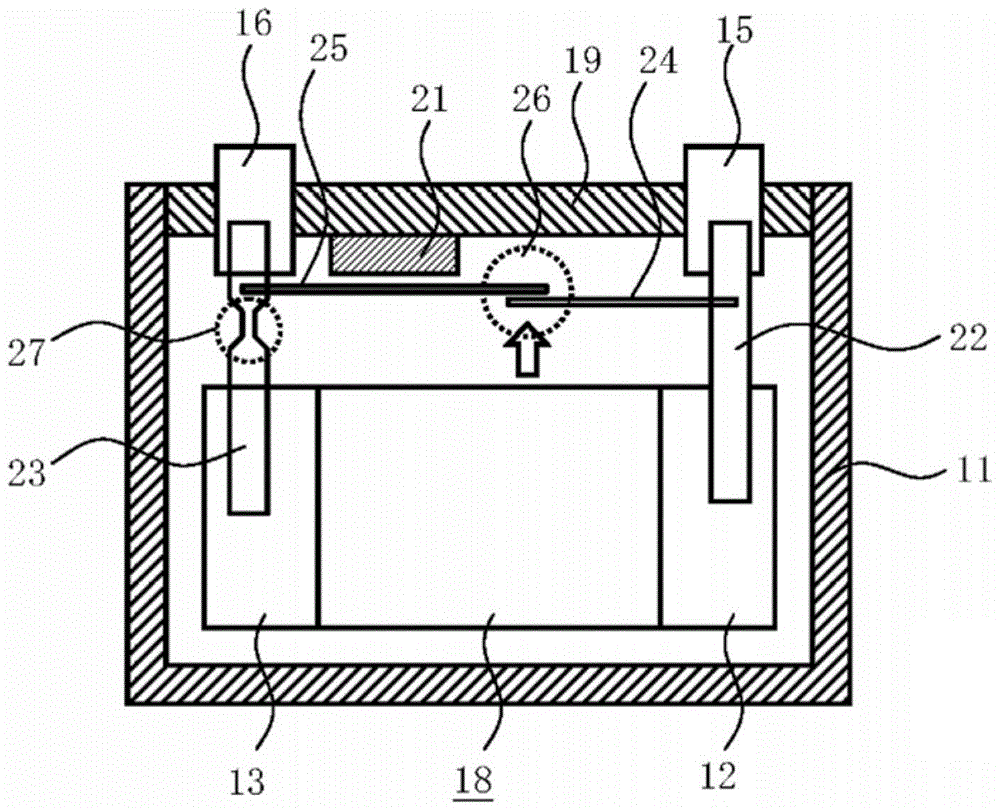

[0025] In the lithium ion secondary battery of this embodiment, a battery with high safety and reliability is realized by arranging an overcharge prevention mechanism inside the battery case in the lithium ion secondary battery.

[0026] That is, the lithium ion secondary battery includes: an electrode assembly formed by winding a positive electrode, a separator, and a negative electrode; an organic electrolyte; a positive electrode lead connected to the positive electrode; a negative electrode lead connected to the negative electrode; and a built-in overcharge prevention mechanism, the battery can is sealed by a cover body, a positive terminal portion fixed to the cover body and connected to the positive electrode lead; and a positive terminal portion fixed to the cover body and connected to the negative electrode lead Connect the negative terminal part.

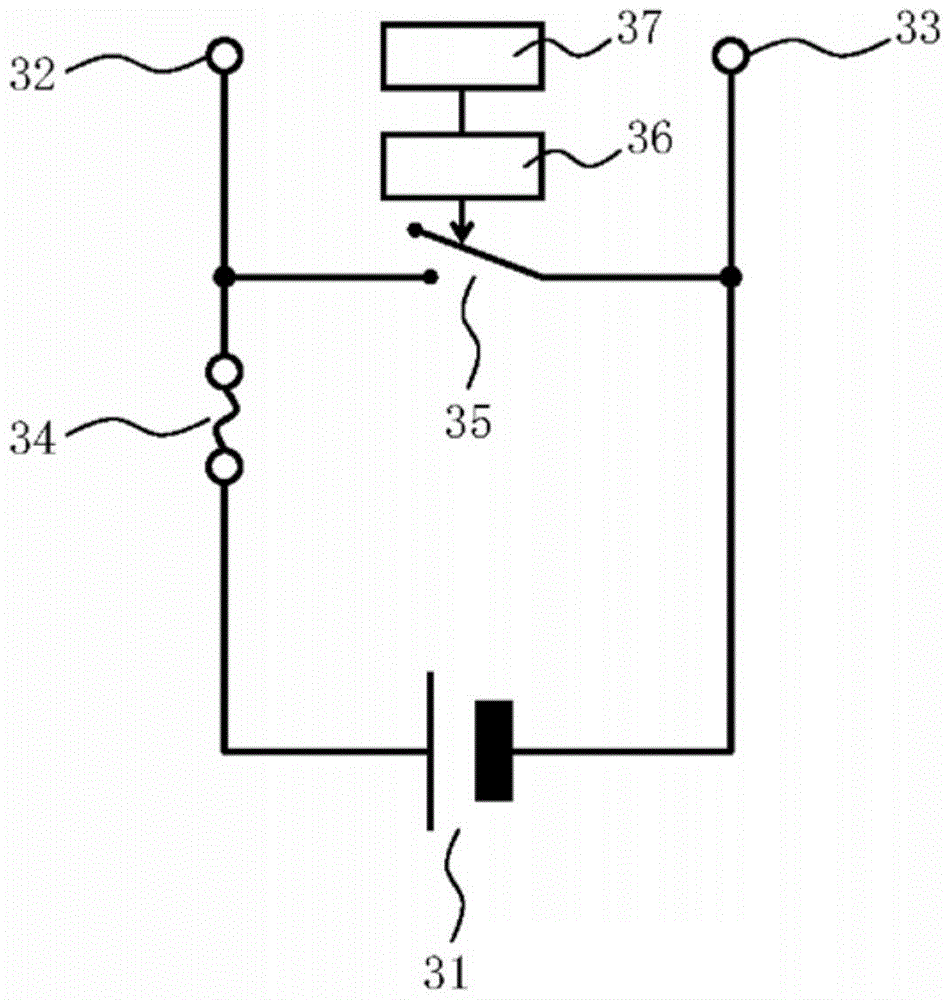

[0027] Further, the overcharge prevention mechanism includes: a voltage detection unit that detects that the voltage betw...

no. 2 approach ]

[0087] In the above-described embodiment, when the lithium ion secondary battery is in an overcharged state during charging, the fuse body is blown by the action of the overcharge prevention mechanism to cut off the charging current. Charge energy also accumulates and remains in the power generator of the ion secondary battery. In the case of disposing of such a battery, when a situation such as a short circuit between battery electrodes occurs, there is a possibility that energy is released violently and a fire may occur.

[0088]This embodiment is for realizing a mechanism for safely releasing residual energy in an overcharged lithium ion secondary battery.

[0089] The lithium ion secondary battery of this embodiment is as Figure 7 shown, except figure 2 In addition to the configuration of the battery of the illustrated first embodiment, the resistance element 71 is connected in parallel with the fuse body 27 .

[0090] use as a circuit diagram of Figure 8 The operat...

Embodiment 1

[0096] Below, use Figure 4 and will Figure 4 The short circuit closing mechanism part of the enlarged Figure 5 The above embodiments will be described in detail through examples.

[0097] The lithium ion secondary battery of the present embodiment detects an overcharged state based on a rise in voltage.

[0098] First, an electrode assembly was produced by the following method.

[0099] will be composed of LiCoO 2 The constituted positive electrode active material was mixed with a solution obtained by dissolving polyvinylidene chloride in N-methylpyrrolidone to prepare a paste-like positive electrode coating material. The paste-like positive electrode paint was passed through a 70 mesh (mesh) mesh to remove large particles, and then applied to a positive electrode current collector composed of a strip-shaped aluminum foil with a thickness of 12 μm except for the collector tab portion. The front and back sides of the body are dried to form a coating film. The dried str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com