Nutritional and safe soy milk making method of soy milk maker

A soymilk machine and pulping technology, applied in dairy products, milk substitutes, applications, etc., can solve the problems of food safety and health impact, soy material deterioration, short appointment time, etc., to achieve fast production of soy milk, simple equipment, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

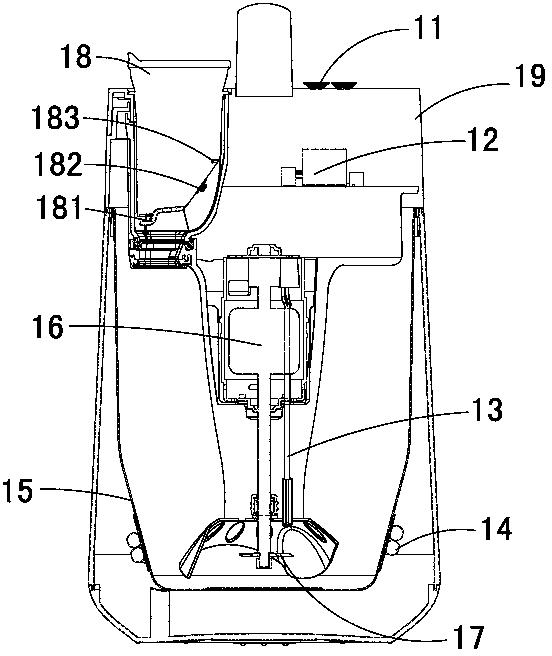

[0044] refer to figure 1 , is a soymilk maker used in a nutritionally safe pulping method of a soymilk maker in this embodiment, including an input device 11, a control unit 12, a first temperature detection device 13, a first heating device 14, a pulping container 15, a motor 16, Crushing tool 17, bubble bean container 18, machine head 19, input device 11 is arranged on the outer surface of machine head 19, input device 11 includes bubble bean button, control unit 12, first temperature detection device 13 and motor 16 are all arranged on the machine head 19 inside, the motor 16 drives the crushing cutter 17, the crushing cutter 17 is located in the pulping container 15, the first temperature detection device 13 extends into the inside of the pulping container 15, the first heating device 14 is arranged on the side wall of the pulping container 15, and the machine head 19 is also provided with a bubble bean container 18, and the bubble bean container 18 is provided with a drai...

Embodiment approach 2

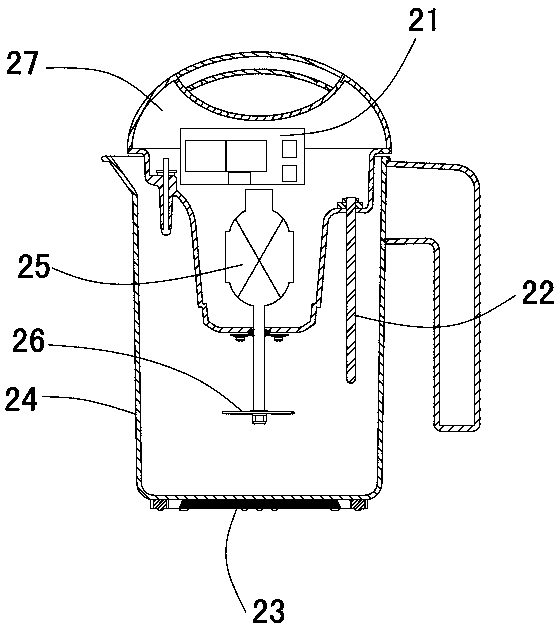

[0067] refer to figure 2 , is the soybean milk machine used in this embodiment, including input device (not shown in the figure), control unit 21, temperature detection device 22, heating device 23, container 24, motor 25, crushing cutter 26, machine head 27, control The unit 21, the temperature detection device 22 and the motor 25 are all arranged inside the machine head 27, the motor 25 drives the crushing cutter 26, the crushing cutter 26 is located in the container 24, the temperature detection device 22 extends into the container 24, and the heating device 23 is located in the container 24 bottom of.

[0068] This example adopts a container 24, which is used for soaking beans and making pulp, which saves the parts of the whole machine and reduces the cost.

Embodiment approach 3

[0070] Such as figure 2As shown, it can also be used as a soybean milk machine used in the third embodiment of the present invention, including an input device (not shown in the figure), a control unit 21, a temperature detection device 22, a heating device 23, a container 24, a motor 25, and a crushing tool 26 , machine head 27, control unit 21, temperature detection device 22 and motor 25 are all located at the inside of machine head 27, and motor 25 drives pulverizing cutter 26, and pulverizing cutter 26 is positioned at container 24, and temperature detecting device 22 stretches into container 24 inside, heating The device 23 is provided at the bottom of the container 24 .

[0071] This embodiment adopts one container 24, which is not only used for soaking beans, but also for making pulp, which saves the parts of the whole machine and reduces the cost.

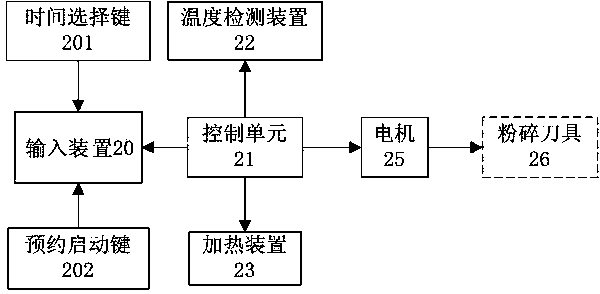

[0072] Such as image 3 Shown is the control schematic diagram of the soymilk machine of this embodiment, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com