Potash fertilizer granulation device

A granulation device and potash fertilizer technology, applied in the direction of liquid separation into droplets and granulation, etc., can solve the problems affecting the use quality of potash fertilizer, damage to biologically active components, and increase production processes, etc., to protect biologically active components, reduce working temperature, Avoid the effect of cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

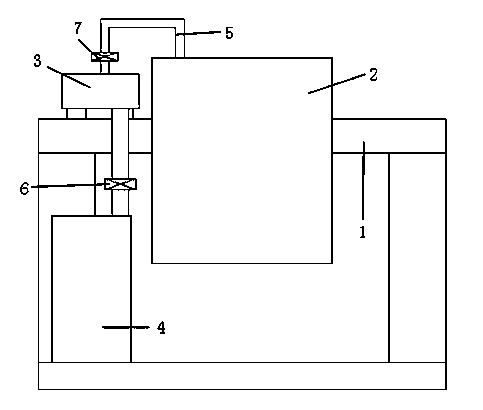

[0009] Such as figure 1 A kind of potassium fertilizer granulation device shown, described potash fertilizer granulation device is made of frame 1, granulation barrel 2, atomizer 3 and water storage tank 4, described granulation barrel 2, atomizer 3 and The water storage tanks 4 are all installed on the frame 1, and the atomizer 3 is connected to the water storage tank 4 and the granulation barrel 2 respectively through a conduit 5, wherein the atomizer 3 and the water tank 4 are connected with a water pump 6 on the conduit, A booster pump 7 is additionally provided on the conduit connecting the atomizer 3 and the granulation barrel 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com