A Three-Point Cylindrical Rolling Knife

A hob and circular rolling technology, which is applied in the field of three-point outer circular rolling knives, can solve the problems of small adjustment range of rolling knives, low processing efficiency, and affecting processing accuracy, etc., to overcome small processing range, improve processing accuracy, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

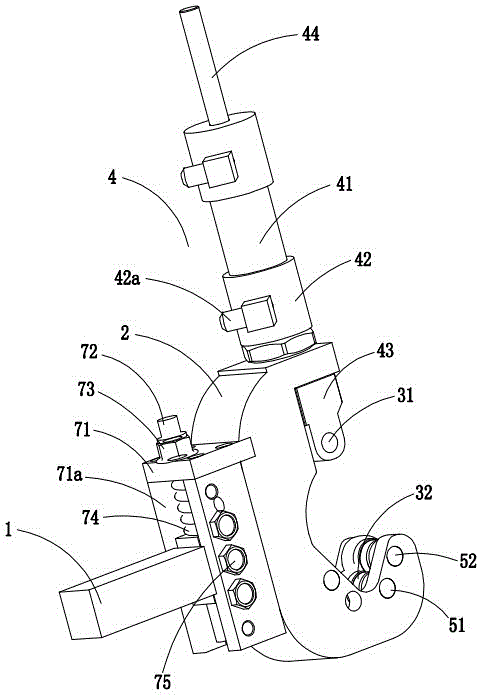

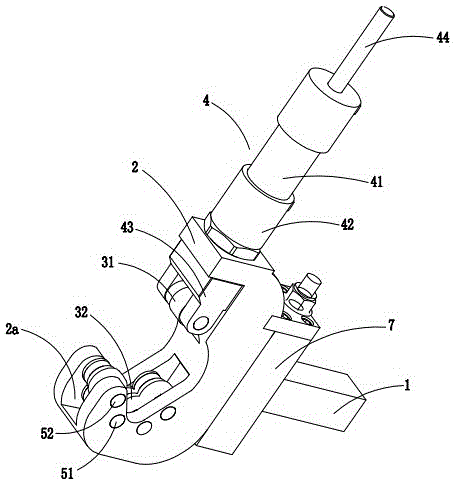

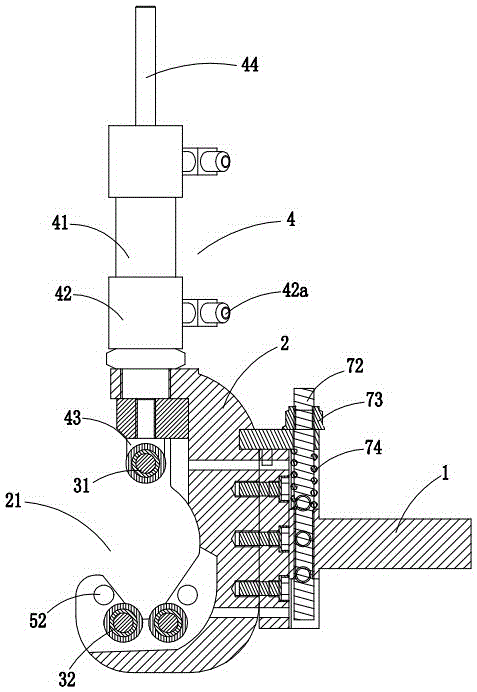

[0031] Such as Figure 1 to Figure 7 Shown is the structural representation of the present invention,

[0032] The reference signs are: knife handle 1, main body frame 2, hob groove 2a, opening 21, upper hob unit 31, lower hob unit 32, telescopic mechanism 4, bracket 41, telescopic cylinder 42, oil filling port 42a, Extension seat 43, telescopic rod 44, first processing positioning hole 51, second processing positioning hole 52, pin 61, needle roller bearing 62, hob wheel 63, plane bearing 64, gasket 65, adjustment mechanism 7, adjustment Bracket 71, adjustment chute 71a, adjustment screw rod 72, adjustment nut 73, adjustment spring 74, locking bolt 75, smaller diameter processing part 81, larger diameter processing part 82.

[0033] Such as Figure 1 to Figure 5 as shown,

[0034] A three-point cylindrical rolling knife of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com