Sliding table

A sliding table and sliding block technology, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing, etc., can solve the problems of unfavorable operation, unfavorable sliding table placement, large length and area occupied by the sliding table, etc., to achieve easy operation , to avoid taking up extra space, the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

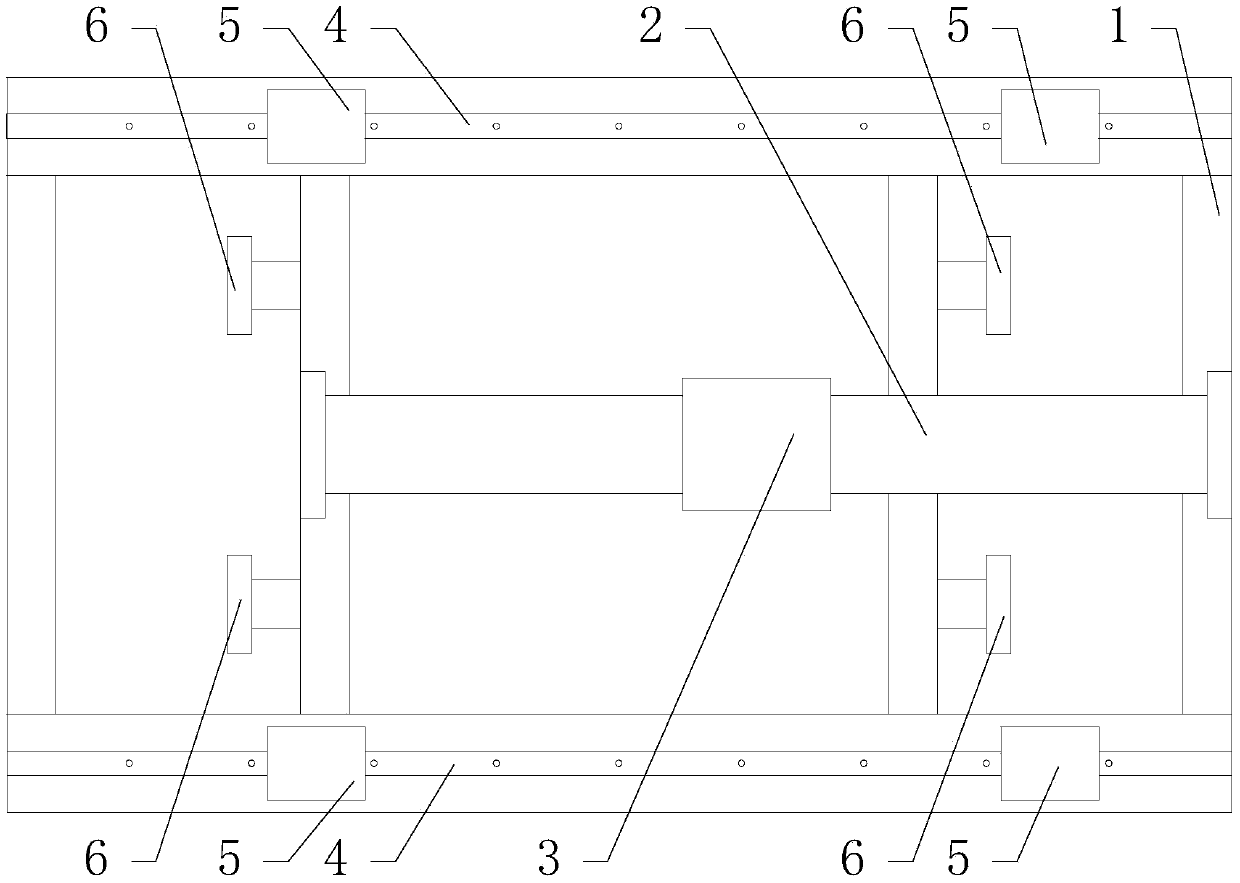

[0011] Such as figure 1 As shown, the slide table of the present invention includes a base 1, a magnetic cylinder 2 is arranged in the base, and a magnetic plate 3 slidably connected with the magnetic cylinder 2 is arranged above the piston of the magnetic cylinder 2. Since the magnetic cylinder 2 does not need to use an external push rod, the piston equipped with a magnetic ring can also drive the magnetic plate 3 to move. Therefore, when working, the magnetic switch on the cylinder can control the reciprocating movement of the piston to drive the magnetic plate above the piston. The component platform mounted above the board 3 and the magnetic board 3 moves.

[0012] In order to improve the efficiency of the moving components, two guide rails 4 parallel to the magnetic cylinder 2 are provided on the base 1 , and each guide rail 4 is provided with two...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap