Heat transfer printing colored tape ink and base material recovering device

A technology of thermal transfer ribbon and recycling equipment, applied in printing, inking device and other directions, can solve the problems of incomplete thermal transfer ribbon and impure polyester film, and achieve simple structure, thorough cleaning and pollution reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

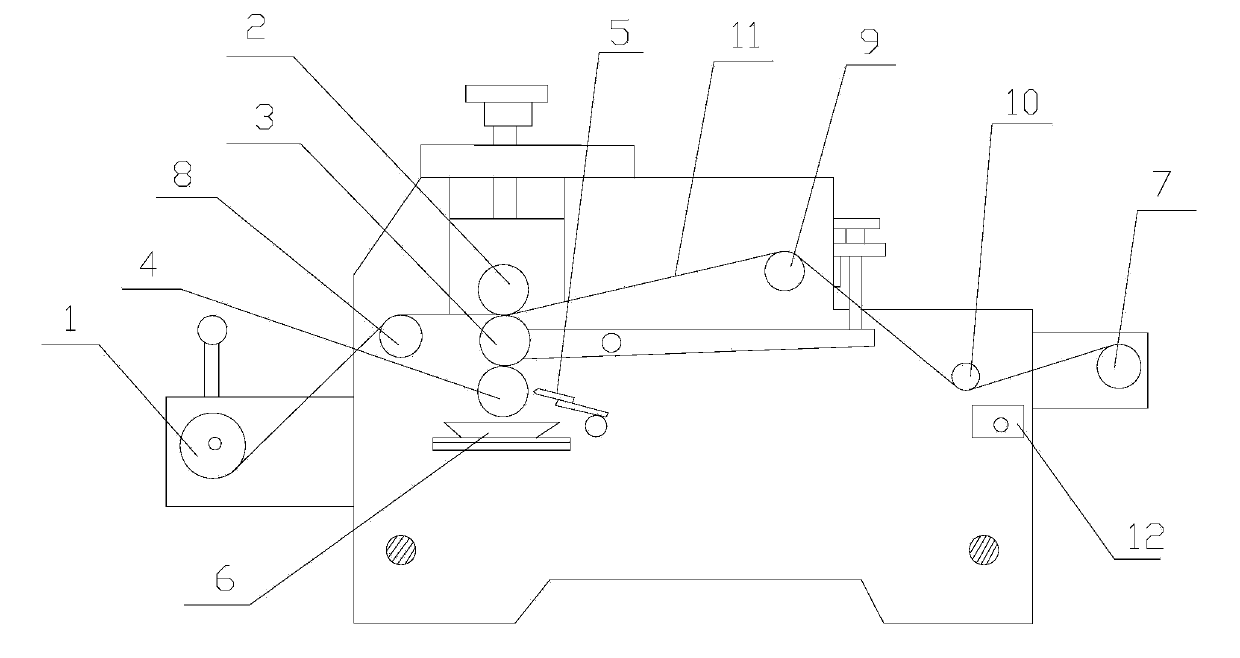

[0012] See figure 1 , a thermal transfer ribbon ink and base material recovery equipment, including unwinding device 1, cooling roller 2, rubber roller 3, heating roller 4, scraper 5, receiving tray 6, winding device 7 and refrigeration device ( Not shown in the figure), the cooling roller 2, the rubber roller 3 and the heating roller 4 are arranged in contact with each other from top to bottom, the cooling roller 2 is connected with the refrigeration device to control its cooling temperature, the heating roller 4 has a heating wire inside, and the rubber roller 3 is in close contact with the heating roller 4, and the rubber roller 3 has a certain temperature through heat conduction. The receiving tray 6 is placed on the side of the heating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com