Adhesive tape film surface treatment method

A surface treatment and thin film technology, which is applied in the field of sealing equipment, can solve the problems of poor barrier properties of tapes and failure to meet industry requirements, etc., and achieve the effects of simple processing, new appearance value, and good visual perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

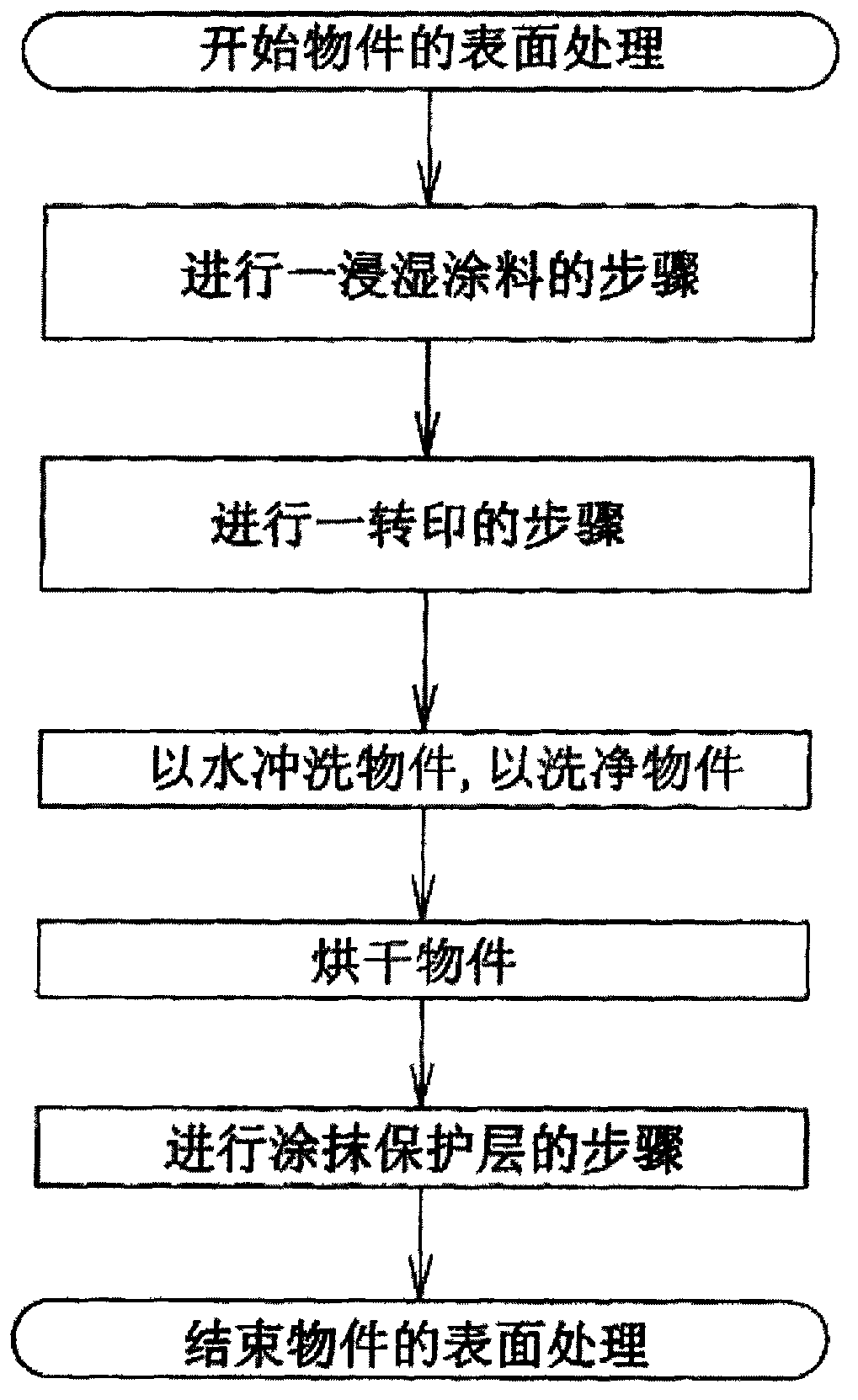

[0014] Such as figure 1 Shown, as the best embodiment of the method for the surface treatment of a kind of adhesive tape film of the present invention, its this surface treatment method comprises the following steps:

[0015] a. Wetting the paint stage, immersing at least a part of a film coated with a paint surface in a liquid, and floating the film on the liquid;

[0016] b. In the cold transfer stage, the object is immersed in the liquid, so that the paint is transferred to the concave-convex lines on the surface of the object;

[0017] c. In the thermal transfer stage, the thermal transfer layer coating is applied to the determined film by a coating machine.

[0018] The thermal transfer layer coating in the thermal transfer stage described in stage C above includes 65% wax, 25% resin, 4% auxiliary agent and 6% colorant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com