A flip-type sand cleaning structure for sand mold transportation

A flip-type, sand-type technology, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of not being able to adapt to the rhythm, high strength, and debris falling off, and achieve the effects of saving manpower, high sand cleaning efficiency, and good sand cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

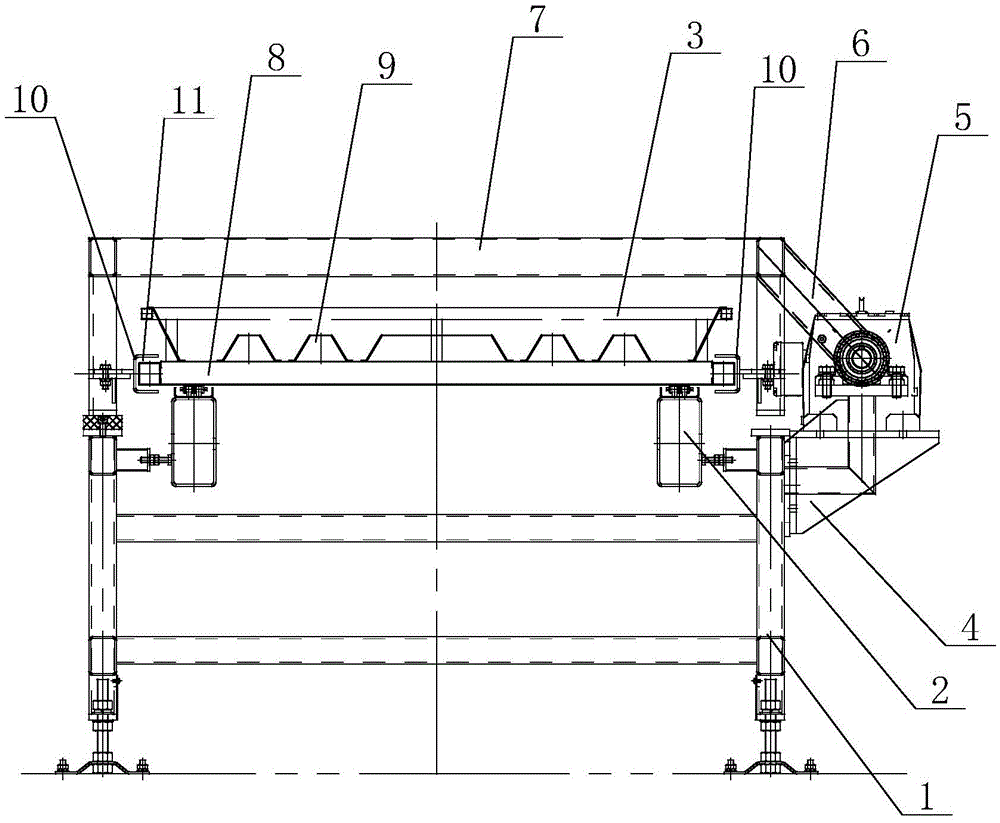

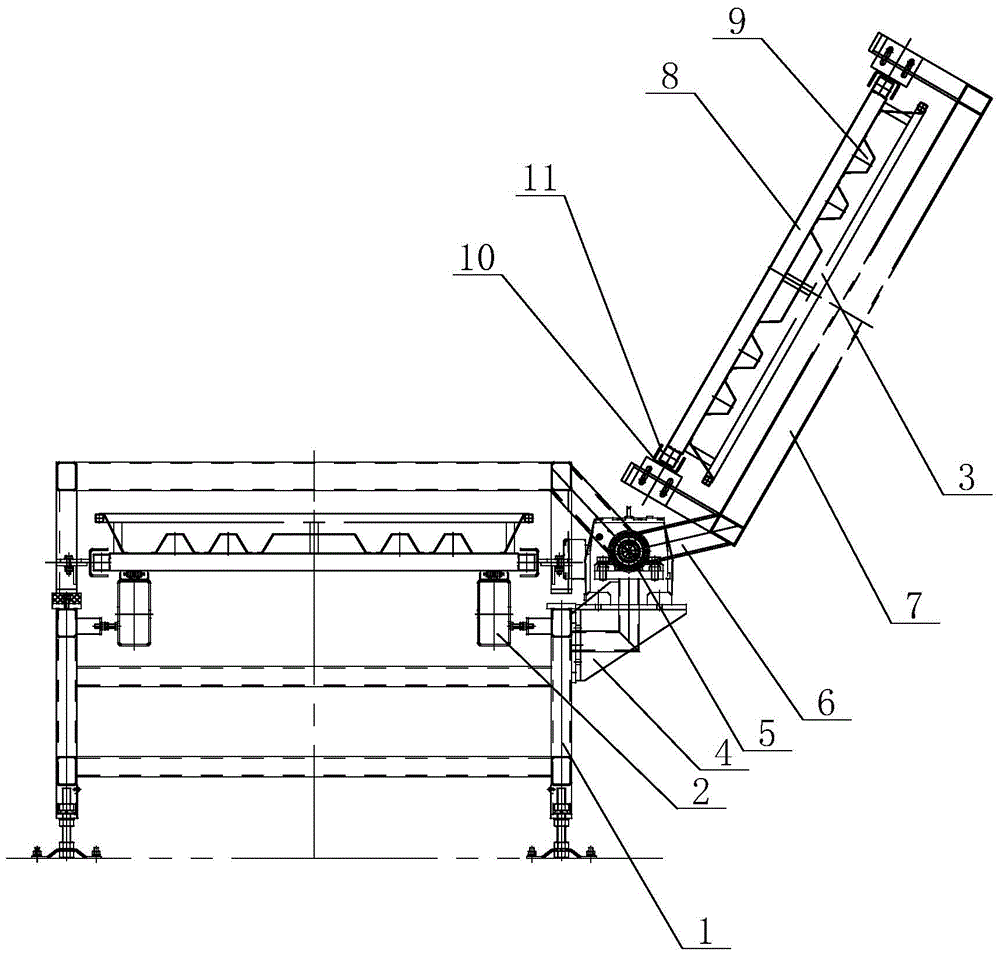

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0017] see Figure 1 to Figure 2 As shown, in this embodiment, a flip-type sand cleaning structure for sand mold transportation includes a conveyor line frame 1 and a conveyor line 2 assembled on the conveyor line frame 1, and the conveyor line 2 is placed on the conveyor line for transportation. A sand mold tray 3, the tray 3 includes a hollow bottom plate 8 and several hollow support platforms 9 welded and fixed on the bottom plate 8, and the support platforms 9 are bent by sheet metal into an isosceles shape with a small top and a large bottom. Ladder structure. One side of the transmission line frame 1 is provided with a mounting plate 4, and a driving motor 5 is installed on the mounting plate 4. The power output end of the driving motor 5 is hinged with a connecting arm 6 through a hinge stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com