Visual inspection system

A technology of visual inspection and control system, applied in the field of visual inspection system, can solve the problems that the robot cannot automatically overcome obstacles, the distance between the robot and obstacles cannot be detected in time, and the large space for clamping and placing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

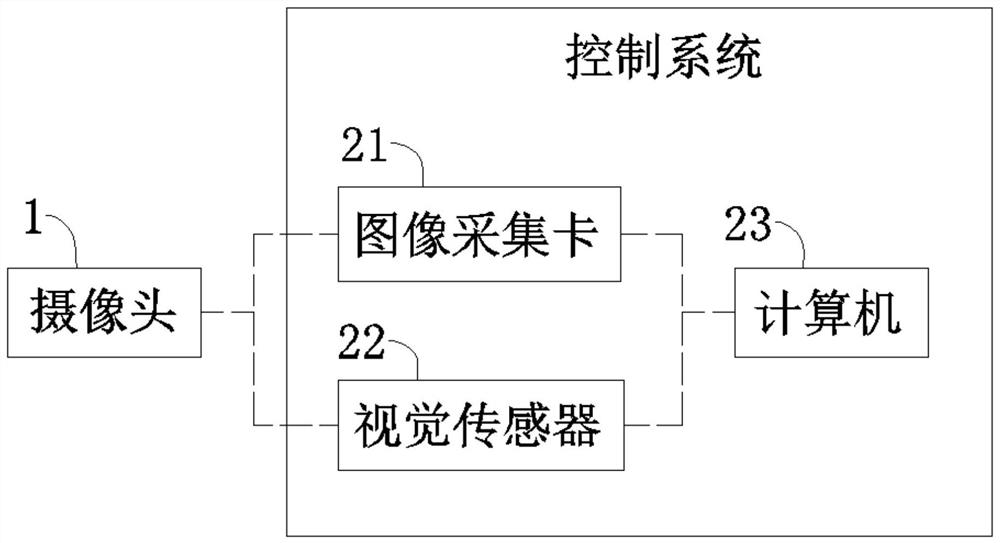

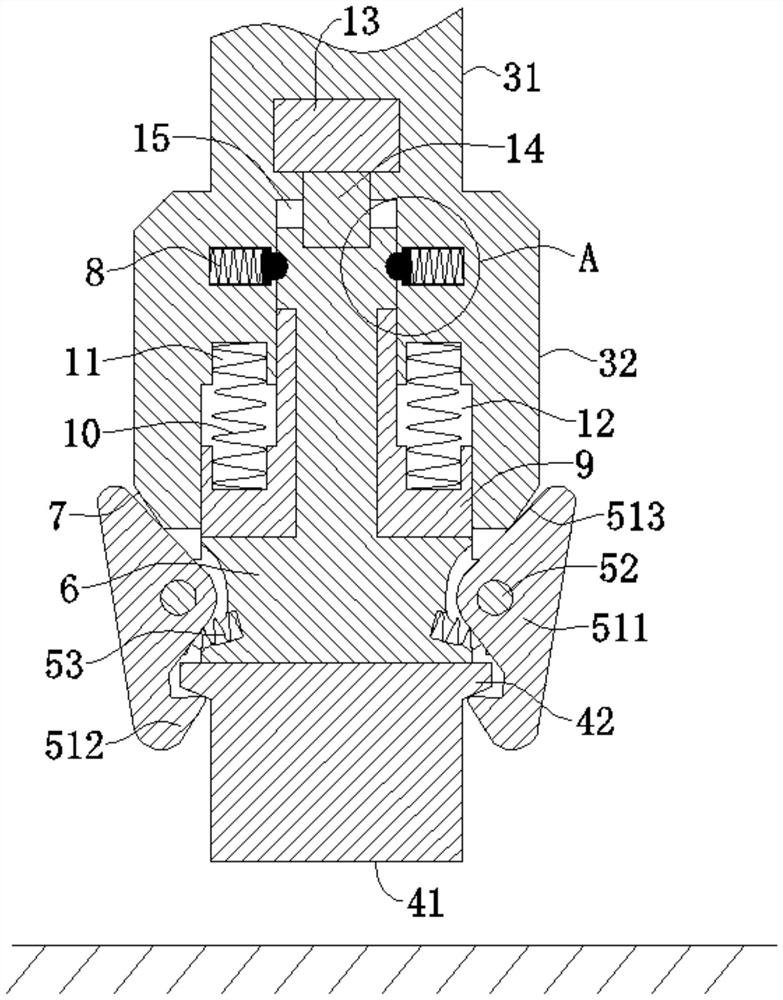

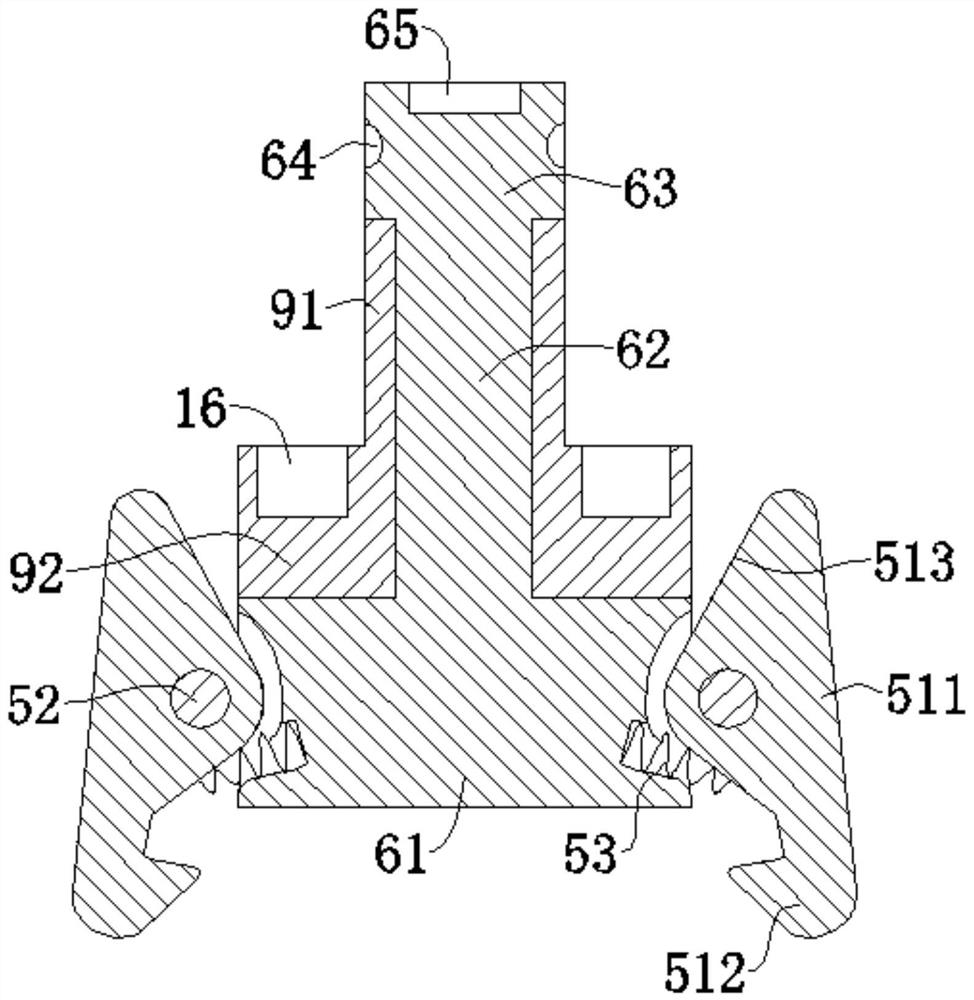

[0037] Embodiment: a kind of visual detection system, as Figure 1-4As shown, it is used to control the movement of industrial robots to realize the gripping and placement of parts. Industrial robots include robot bodies and manipulators. The visual inspection system includes a camera 1 and a control system. The camera 1 is installed on the manipulator of the industrial robot, and the industrial robot is a six-degree-of-freedom robot. The control system includes a computer 23 , an image acquisition card 21 and a visual sensor 22 , one end of the visual sensor 22 and the image acquisition card 21 are respectively connected to the computer 23 through wireless communication, and the other ends are respectively connected to the camera 1 through wireless communication. The image acquisition card 21 is used to obtain the environmental image of the part taken by the camera 1, and to calculate and analyze various obstacles on the clamped or placed part; the visual sensor 22 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com