Alumite waste collection machine

A technology of waste collection machine and anodized aluminum, applied in the field of bronzing, which can solve the problems of large equipment volume, production site and storage impact, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

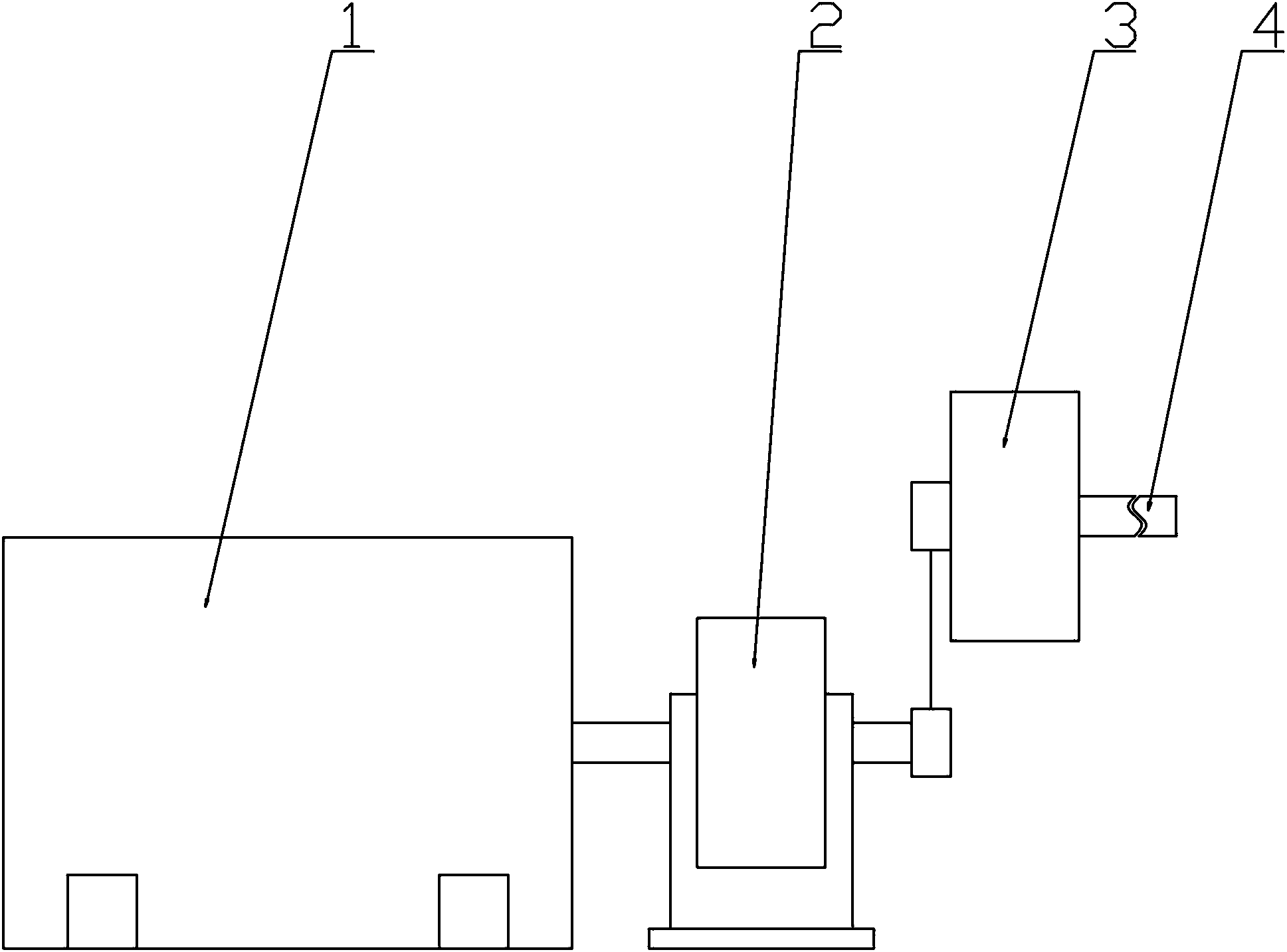

[0013] like figure 1 Among them, an anodized aluminum waste collection machine includes a motor 1 and a reducer 2 connected to the motor, and the reducer 2 is connected to a winding shaft 4 through an electromagnetic clutch 3 .

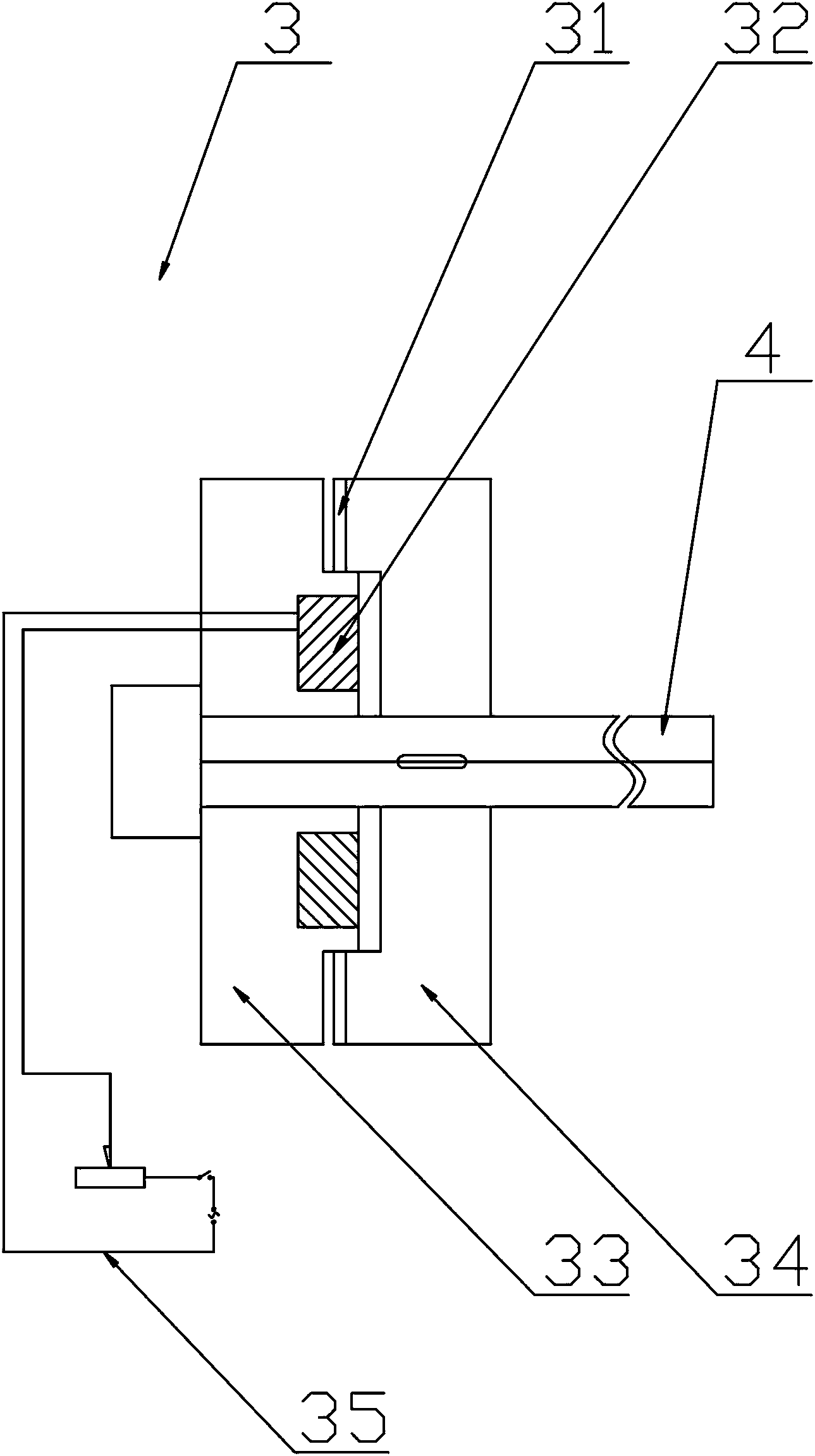

[0014] Described electromagnetic clutch 3 adopts single plate friction clutch.

[0015] like figure 2 Among them, in the electromagnetic clutch 3 described above, an electromagnet 32 is provided on the first transmission disc 33, and the second transmission disc 34 is connected to the winding shaft 4 in an axially slidable manner. The first transmission disc 33 or the second transmission disc 34 A friction plate 31 is provided on it. In an optimized solution, the electromagnet 32 is connected with an adjustment circuit for adjusting the suction force of the electromagnet 32 . The motor and reducer drive the electromagnetic clutch, which controls the winding tension of the rewinding shaft. At the same time, the anodized aluminum passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com