Processing method for strengthening vacuum preloading soft foundation by direct-current electric field

A DC electric field and soft foundation technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of no breakthrough, low permeability and self-blocking, fine solid particles, etc., and achieve the effect of accelerating the seepage speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

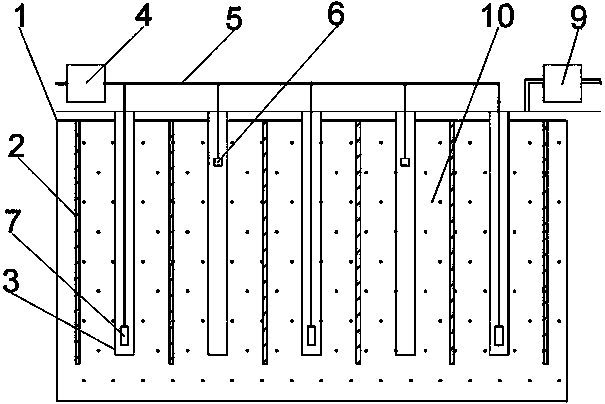

[0043] Such as figure 1 As shown, for a site with a side length of 200m×200m and an area of 40000m 2 Vacuum preloading soft foundation treatment area 1 of the square muddy soil implements the construction of DC electric field enhanced vacuum preloading soft foundation treatment method, the design depth of soft foundation treatment is 30m, and the construction operation is carried out according to the following implementation steps:

[0044] 1) Set up a DC electric field operation well 3 in the vacuum preloaded soft ground treatment area 1. The DC electric field operation well 3 is installed in a manner of burying plastic pipes vertically underground. The end of the plastic pipe facing downward is sealed, and the plastic pipe There are several permeable holes on the pipe wall, and a filter screen is arranged outside the permeable holes.

[0045] The setting of the DC electric field operation well 1 is carried out simultaneously with the construction of the plastic drainage b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com