Construction Technology of Vacuum Dynamic Consolidation Composite Drainage System for Drought Fill Soft Soil Foundation

A technology of dynamic consolidation and drainage system, which is applied in basic structure engineering, soil protection, construction, etc. It can solve the problems of improving the soft soil strength in the deep layer of soft soil foundation, and can not effectively reduce the water level before ramming, so as to achieve obvious bearing capacity of the foundation , controllable settlement, and improved foundation bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

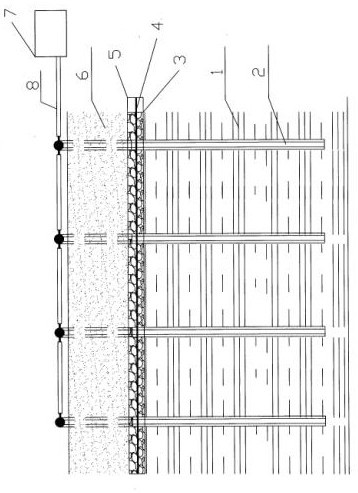

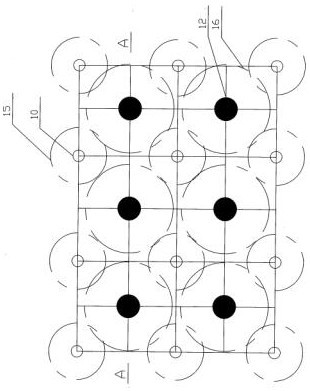

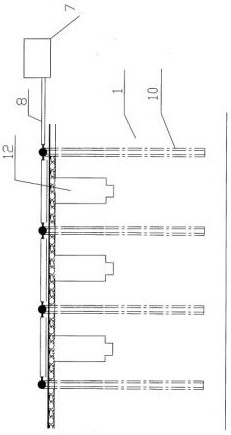

[0028] A vacuum dynamic consolidation composite drainage system for dredging soft soil foundations, comprising an undisturbed soft soil layer 1, on which a 200mm-thick graded crushed stone initial binding layer 3 is arranged, and a 200mm-thick grade Composite vertical drainage pipe bodies 2 are arranged at intervals on the initial bonding layer 3 with gravel, and vertical drainage core pipes 9 are arranged inside the composite vertical drainage pipe body 2 . A water inlet 11 is provided on the top, a water suction port is provided on the side wall of the vertical drainage core pipe 9, and a water inlet is provided between the outer side wall of the vertical drainage core pipe 9 and the inner side wall of the composite vertical drainage pipe body Tubular filter membrane 10, the top of the vertical drainage core pipe 9 is connected with a horizontal vacuum suction pipe 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com