Direct heating air source heat pump crude oil heating system

An air source heat pump and heating system technology, applied in the petroleum industry, can solve the problems of high cost of use, low heat transfer efficiency, easy freezing of high-level expansion water tanks, etc., and achieves low operating costs, high heat transfer efficiency and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

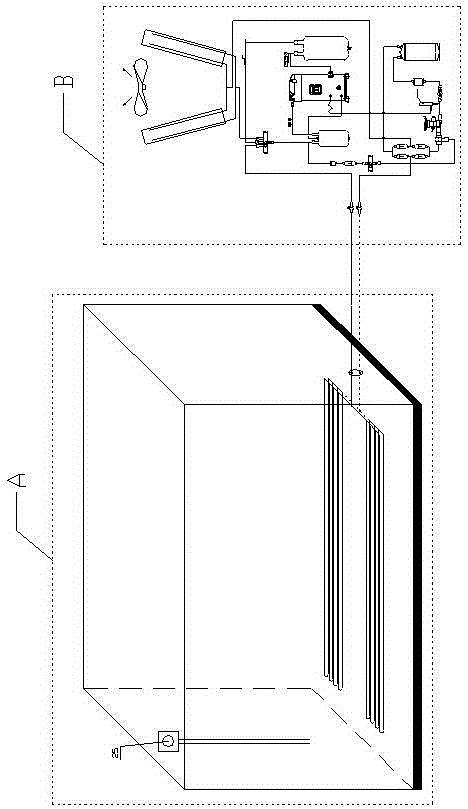

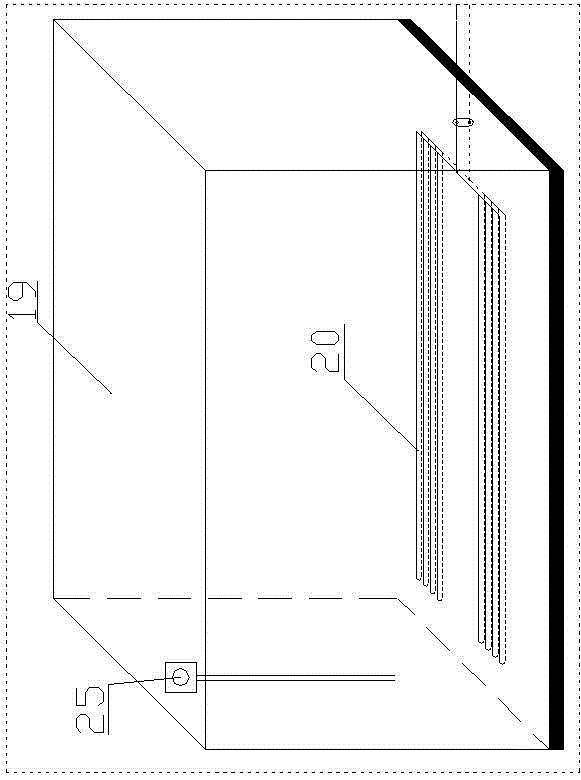

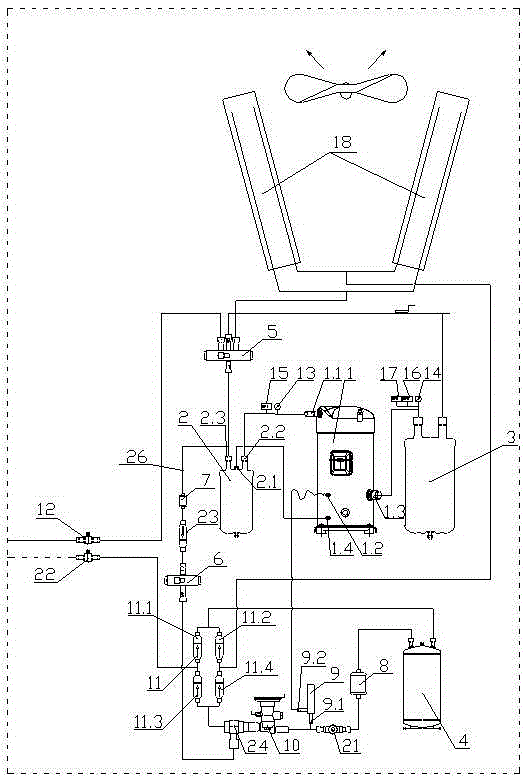

[0025] see Figure 1-8 , The present invention relates to a direct heating air source heat pump crude oil heating system, which includes an air source heat absorption device, a storage tank 19 and a coil heat exchanger 20, and the air source heat absorption device includes a compressor 1, an oil separator 2, Gas-liquid separator 3, liquid accumulator 4, four-way reversing valve 5, drying filter 8, liquid injection valve 9, one-way valve group 11, evaporative surface cooler 18 and lead pipe 26, the compressor 1 has The exhaust port 1.1 is connected to the air inlet of the oil separator 2, the oil outlet 2.1 of the oil separator 2 is connected to the oil return port 1.4 of the compressor 1, and the exhaust port 1.1 of the compressor 1 is connected to the oil separator 2 A high pressure gauge 13 and a high pressure controller 15 are installed on the connecting pipe between the air inlets.

[0026] see Figure 1-4 , when the temperature is high (greater than 7 ℃), the direct hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com