Upper probe and lower probe detection system with position capable of being calibrated accurately and calibration method thereof

A detection system, precise technology, applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of deformation, failure to provide solutions, failure and other problems of vacuum insulation panels, and achieve the effect of ensuring precise alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

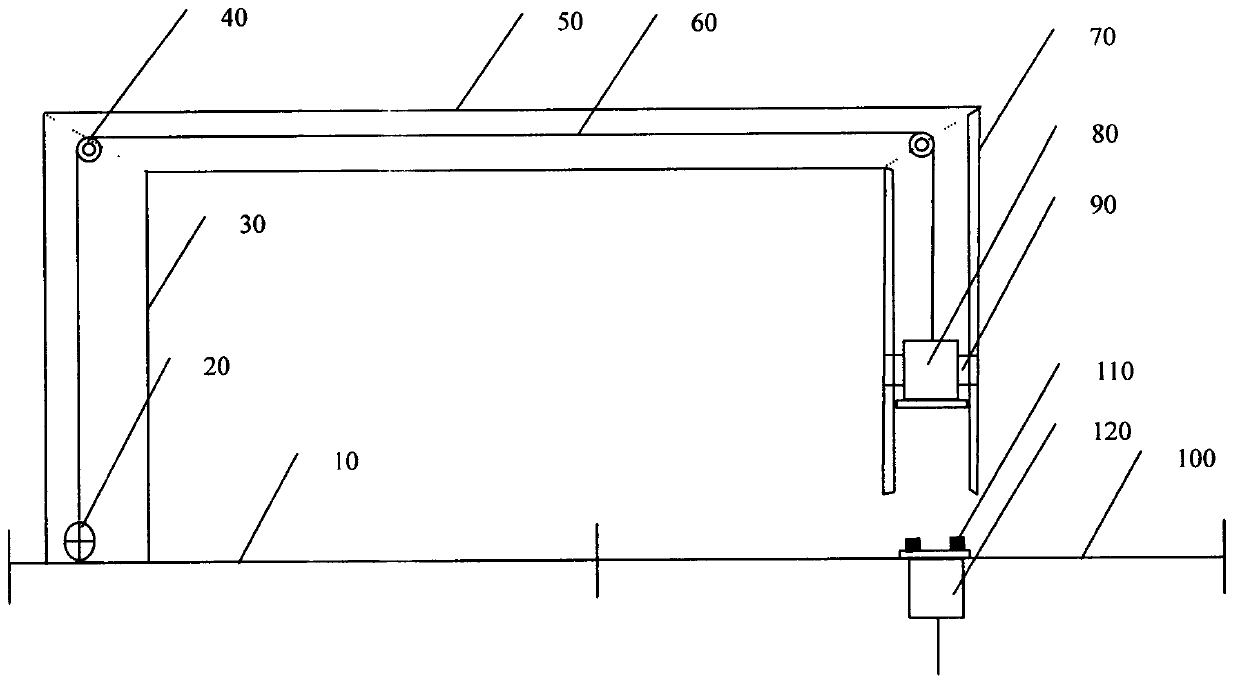

[0022] Such as figure 1 As shown, a detection system for upper and lower probes whose positions can be accurately calibrated is characterized by 10, support platform; 20, electric hoist; 30, round tube 1; 40, fixed pulley; 50, round tube 2; 60, steel wire rope 70, round tube 3; 80, upper probe; 90, upper probe limiter; 100, detection platform; 110, calibration ring block; 120, lower probe.

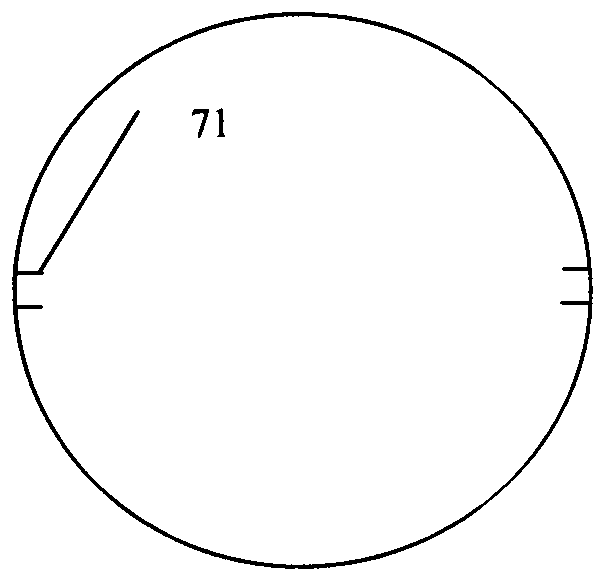

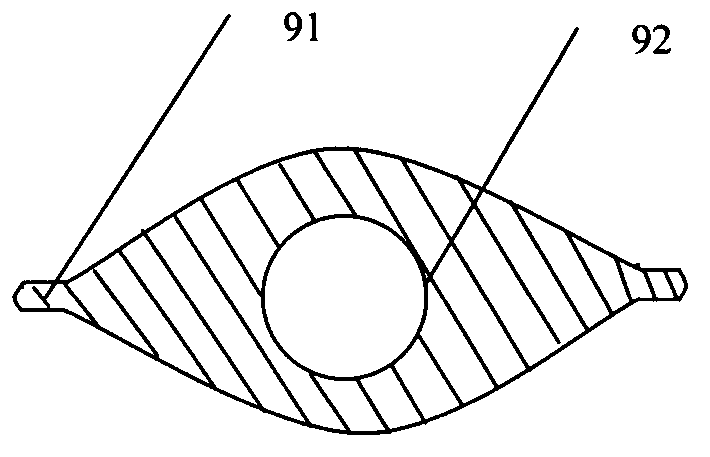

[0023] figure 2 It is a cross-sectional view of 70. Round tube 3, characterized by 71. Round tube card slot; image 3 It is a cross-sectional view of 90, the upper probe limiter, which is characterized by 91, PTFE, 92, rubber; Figure 5 It is a side view of 80, upper probe and 120, lower probe, characterized by 81, circular groove, 121, circular groove; Image 6 It is 100. The top view of the detection platform, which is characterized by 120, the lower probe, 101-104, the limit rod, 105, the pulley, 106, and the fixing clip.

[0024] Reference figure 1 , 2 , 3, 4, 5, 6, to complete the calibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com