Anti-fog self-cleaning lens and preparation method thereof

A self-cleaning and lens technology, applied in the field of preparation of anti-fog self-cleaning lenses, can solve problems such as high environment, technical requirements, and difficulty in industrialization, and achieve the effect of facilitating daily life and stabilizing vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

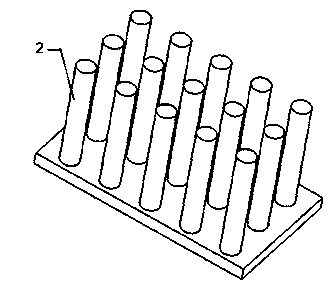

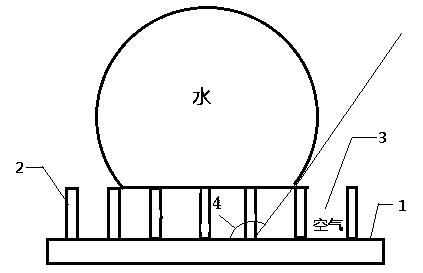

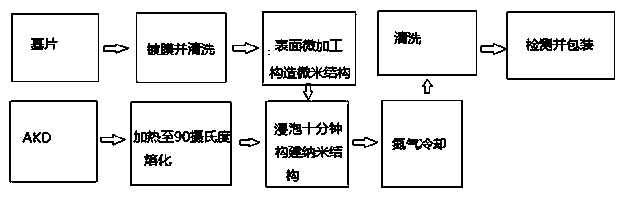

[0021] Such as Figure 1-2 As shown, the lens surface 1 is micromachined by laser micromachining to obtain a mirror surface with uniformly arranged columnar structures 2, the diameter of the columns is 10-15 microns, the pitch is 20-30 microns, and the height is about 60-70 microns. Between the body is the air cushion 3. Then a layer of nanostructure is constructed by combining microstructure with alkyl ketene dimer (AKD) treatment. AKD is uniformly distributed on the microprocessed surface in the form of particles, and the particle size is about 130 nm, so that the lens forms a contact angle of 4 The imitation lotus leaf super-hydrophobic mirror surface is greater than 140 degrees. The columnar structure 2 has a large relative column height (Hr=2), which can ensure a composite wet state and a small relative column width (0.33≤Ar≤0.75), and can obtain a contact angle of not less than 140 degrees. And a layer of air cushion 3 is formed in the columnar groove to further reduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com