Waste heat utilization projector heat dissipation system based on thermoelectric conversion

A technology of thermoelectric conversion and heat dissipation system, applied in thermoelectric device parts, instruments, optics, etc., can solve problems such as the need for working medium and unsuitability for projector use, to reduce the temperature of the working environment, improve the working efficiency of the instrument, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

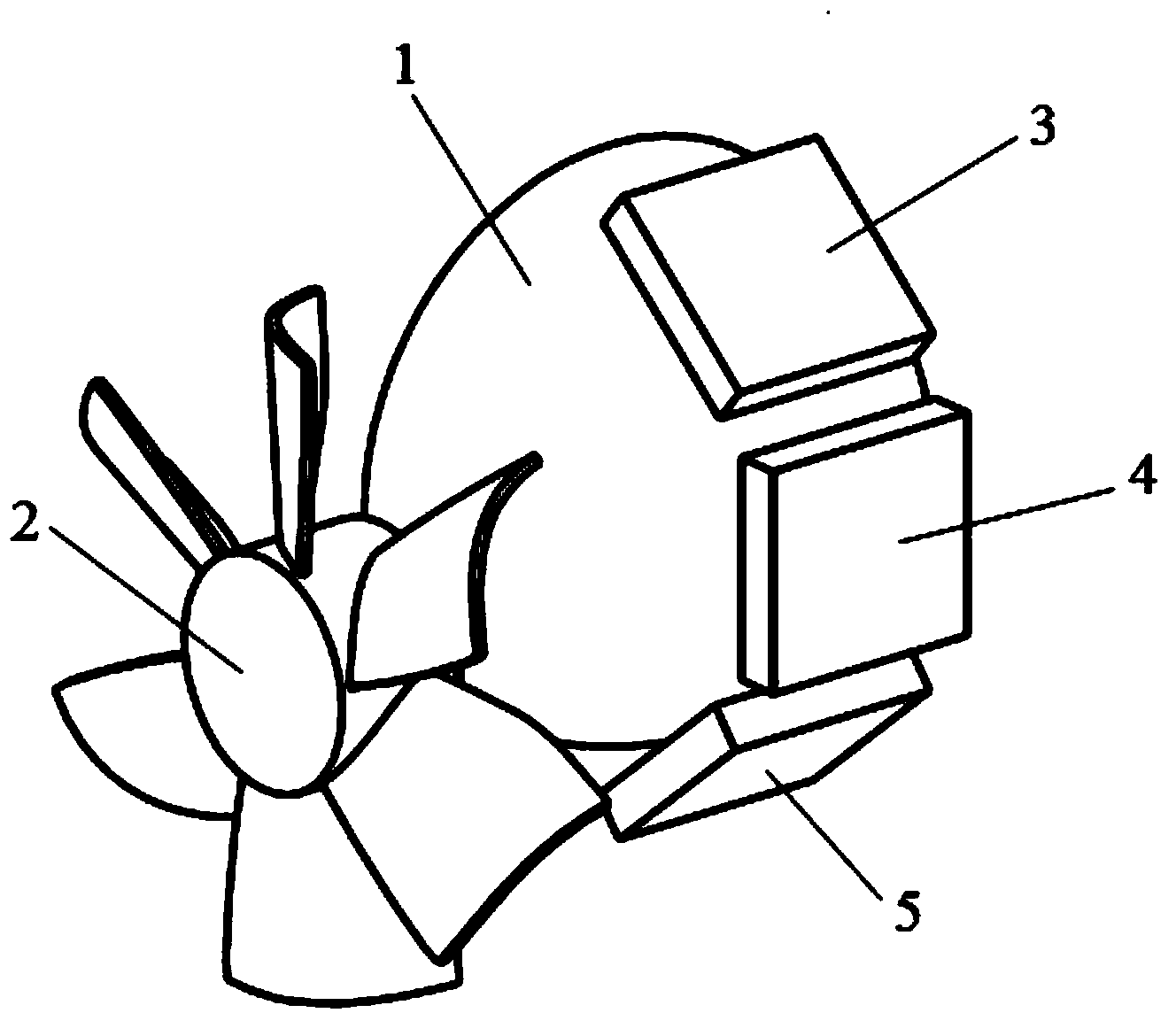

[0016] Examples of the present invention are figure 1 As shown, the present invention includes a projector bulb 1, a DC fan 2, a first thermoelectric conversion material 3, a second thermoelectric conversion material 4 and a third thermoelectric conversion material 5, the first thermoelectric conversion material 3, the second thermoelectric conversion material 4 and The hot end of the third thermoelectric conversion material 5 is respectively connected to the upper surface, the rear surface and the lower surface of the projector bulb 1, the DC fan 2 is arranged on the left side of the projector bulb 1, the first thermoelectric conversion material 3, the second thermoelectric conversion The electric energy generated by the material 4 and the third thermoelectric conversion material 5 is transmitted to the DC fan 2 through wires, and the first thermoelectric conversion material 3, the second thermoelectric conversion material 4 and the third thermoelectric conversion material 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com