Method for avoiding mistaken input of tool radius compensation value during numerical control machining

A tool radius and compensation value technology, which is applied in the direction of program control, computer control, general control system, etc., can solve problems such as wrong input of tool radius compensation value, parts processing out-of-tolerance, scrapping, etc., and achieve significant economic benefits and good social benefits , the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

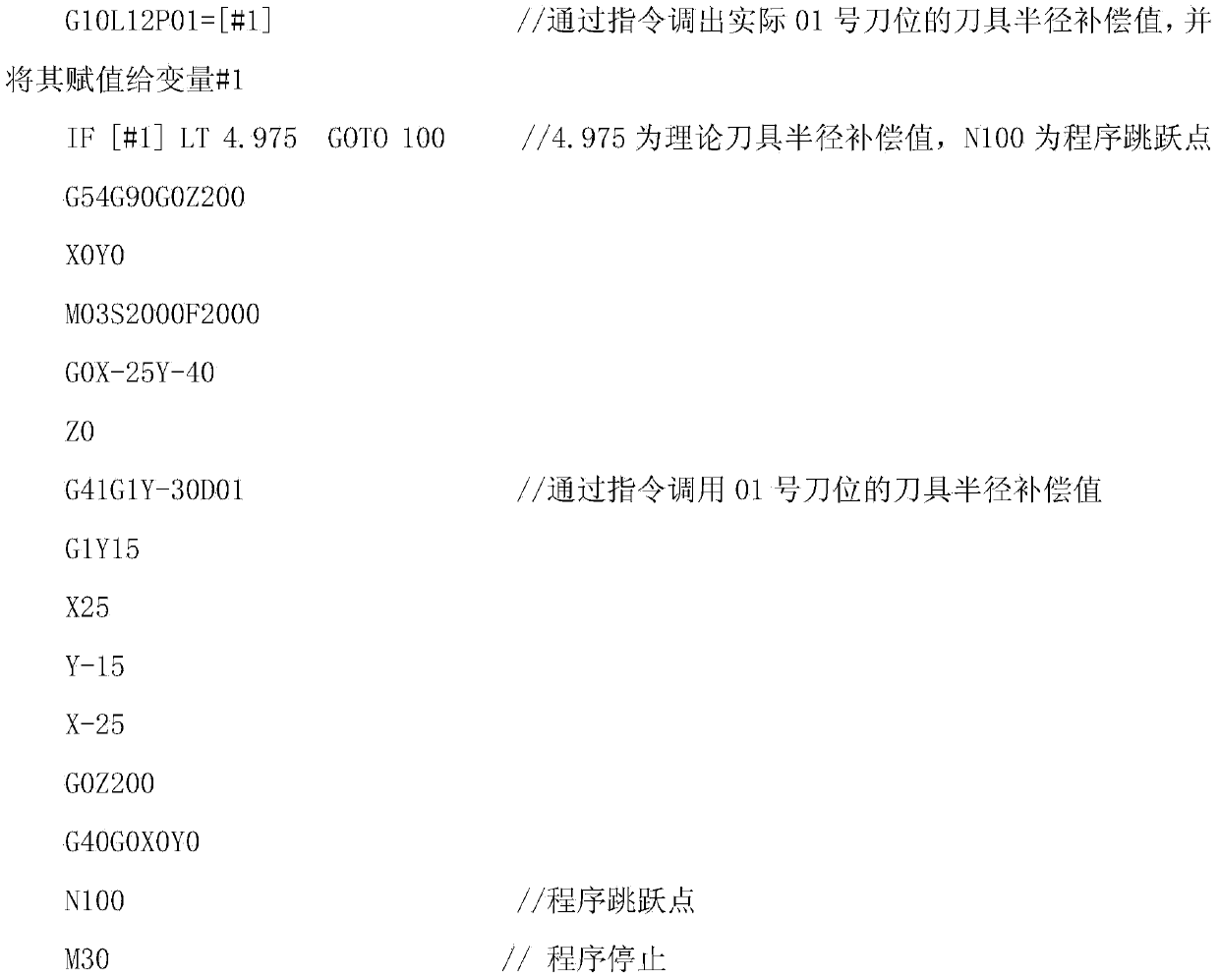

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

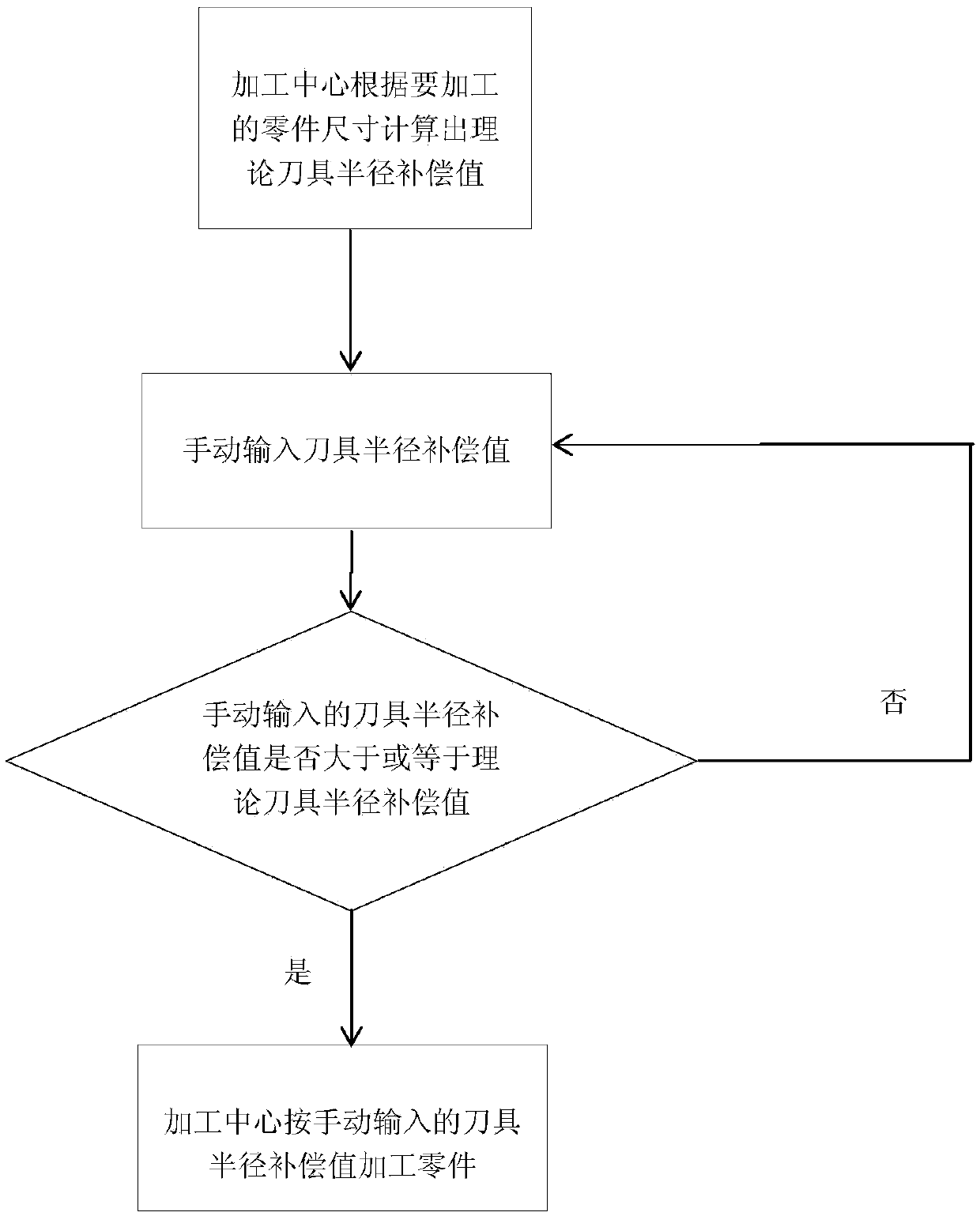

[0013] Such as figure 1 As shown, taking the outer contour milling of parts with Φ10 end milling cutter as an example, the length of the part is guaranteed to be 50±0.05mm, and the width is 30±0.10mm. The method to avoid mistakenly inputting the tool radius compensation value in NC machining includes the following steps:

[0014] Step 1: The machining center calculates the theoretical tool radius compensation value according to the size of the part to be processed;

[0015] When machining the outer contour of a part: The theoretical tool radius compensation value = the actual radius of the tool + half of the minimum lower deviation value in the contour size of the processed part, that is, the theoretical tool radius compensation value = 5-0.05 / 2 = 5-0.025 = 4.975mm;

[0016] Step 2: Manually input the tool radius compensation value;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com