Device for welding assembly of aero-engine combustion chamber diffuser casing mounts

An aero-engine, welding and assembly technology, used in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of unreliable positioning, unsecured position, easy burns on hands, etc., to prevent out-of-tolerance or scrap, Guaranteed uniqueness and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

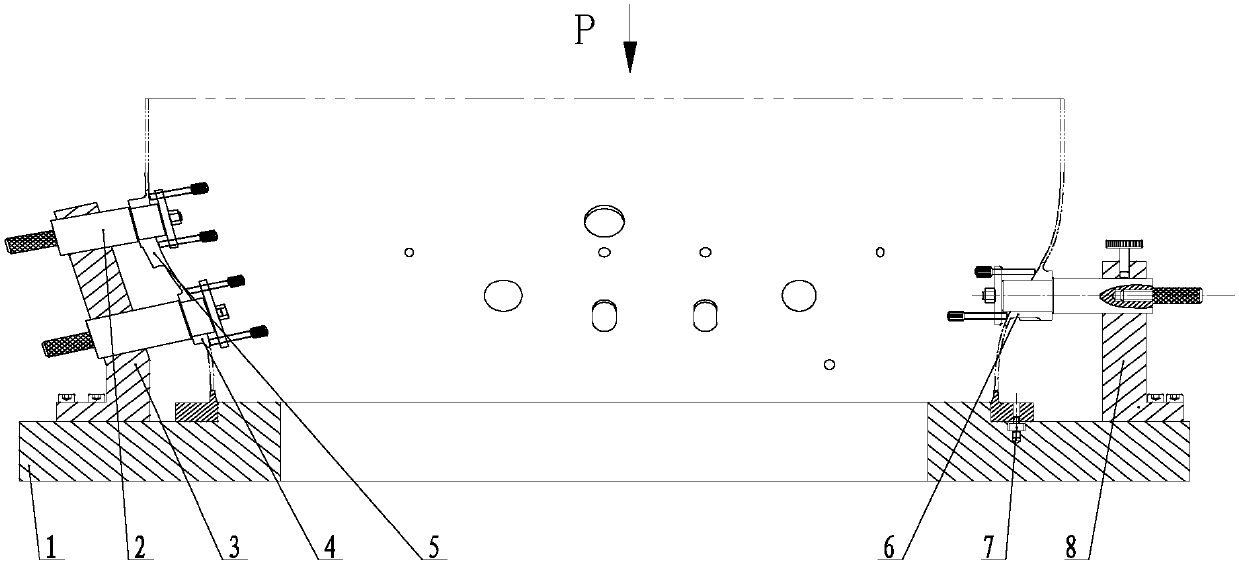

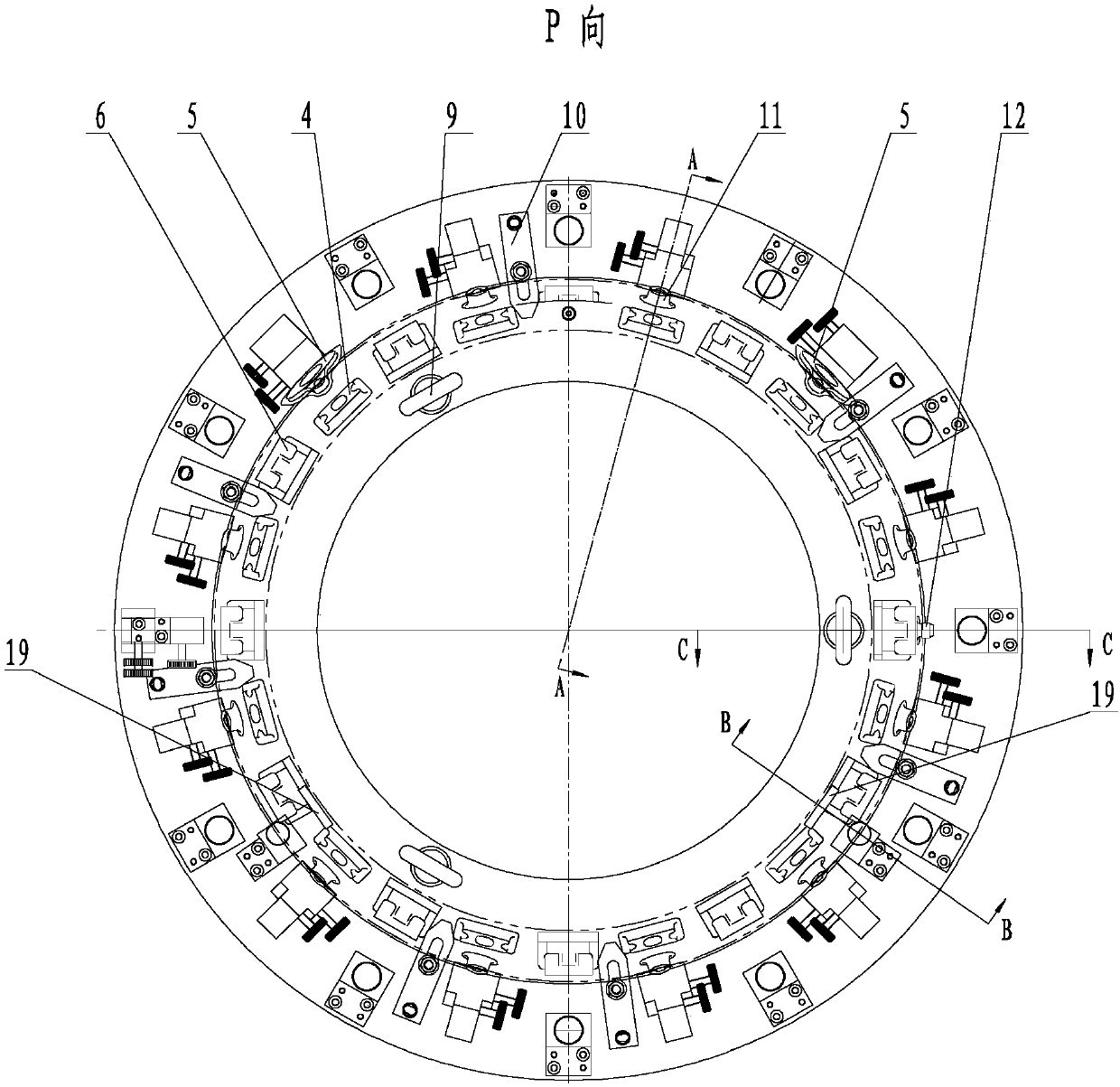

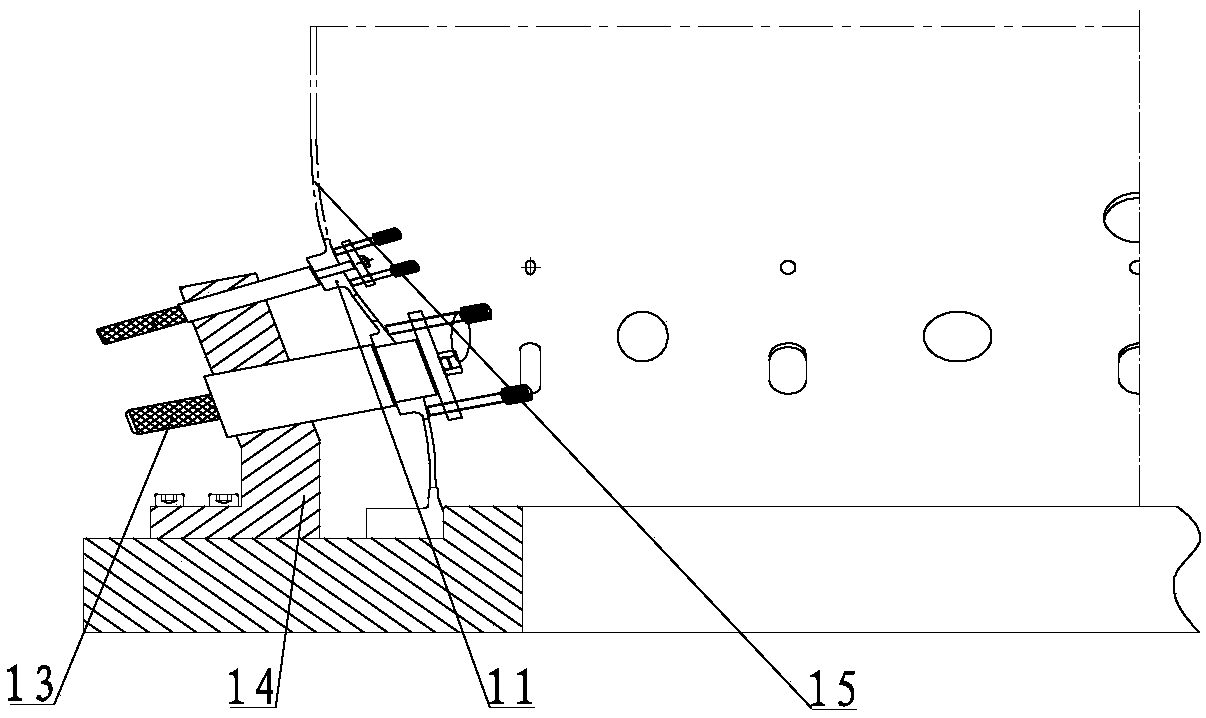

[0026] The device used for the welding and assembly of the diffuser casing mounting seat of the aero-engine combustor of the present embodiment has a structure such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 shown. In the embodiment, six types of mounts are distributed on the diffuser casing, which are 12 evenly distributed first-type mounts 4, two second-type mounts 5 symmetrically distributed with respect to the reference hole, and 12 evenly distributed The third type of mounting base 6, 10 evenly distributed fourth type of mounting bases 11, one fifth type of mounting base 12, and three sixth type of mounting bases 19 (unevenly distributed). There are also six types of support assemblies for respectively supporting and positioning the six types of mounting seats, which are the first type support assembly 3, the second type support assembly 8, the third type support assembly 14, and the fourth type support assembly Assembly 20, Type 5 mount assembly 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com