Brush direct-current motor

A technology of DC motors and motors, applied in DC commutators, electrical components, electromechanical devices, etc., can solve problems such as increased power coefficients, achieve the effects of reducing calorific value, suppressing the increase in size, and reducing circulating current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

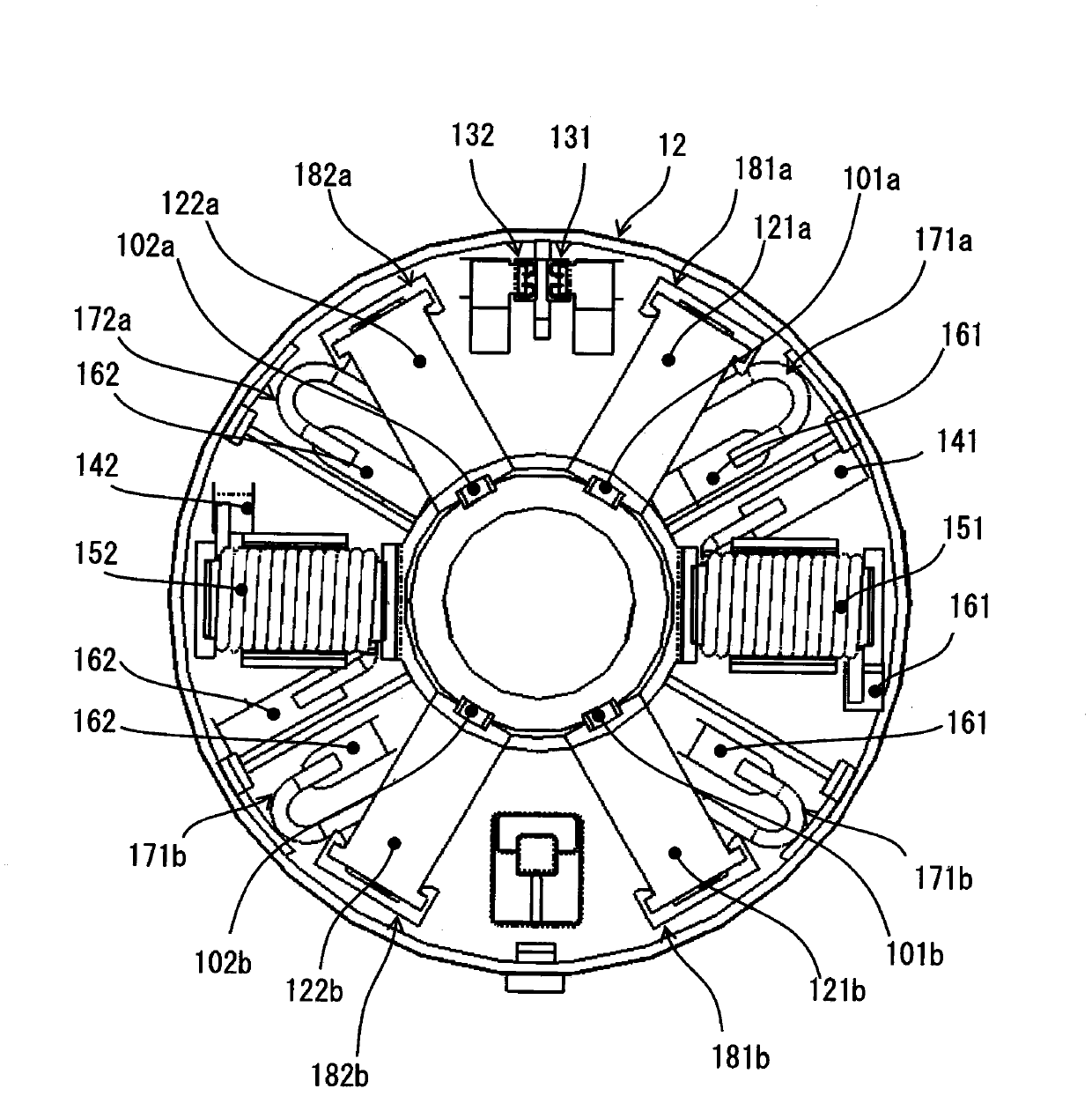

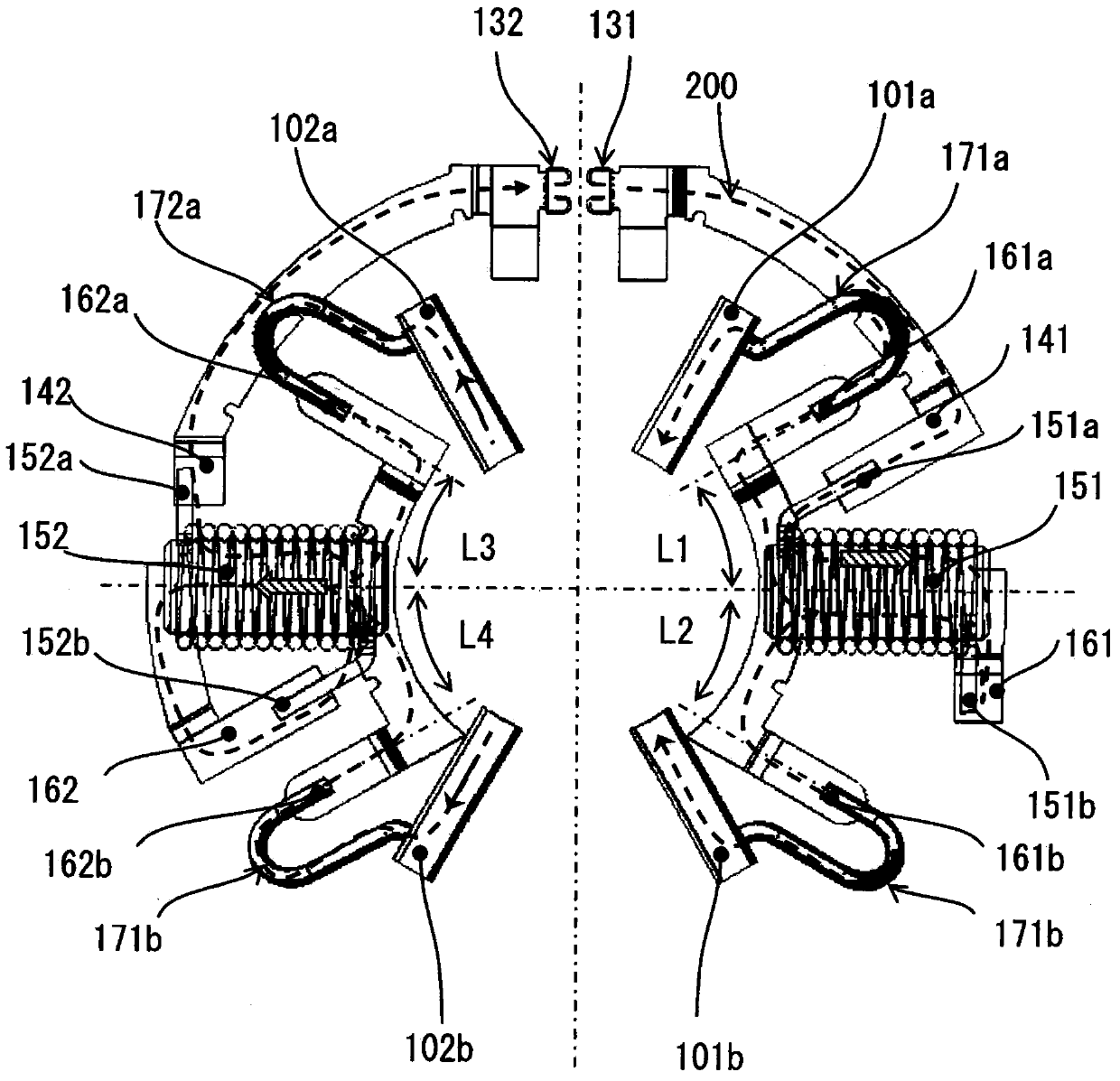

[0048] Hereinafter, an embodiment will be described using the drawings.

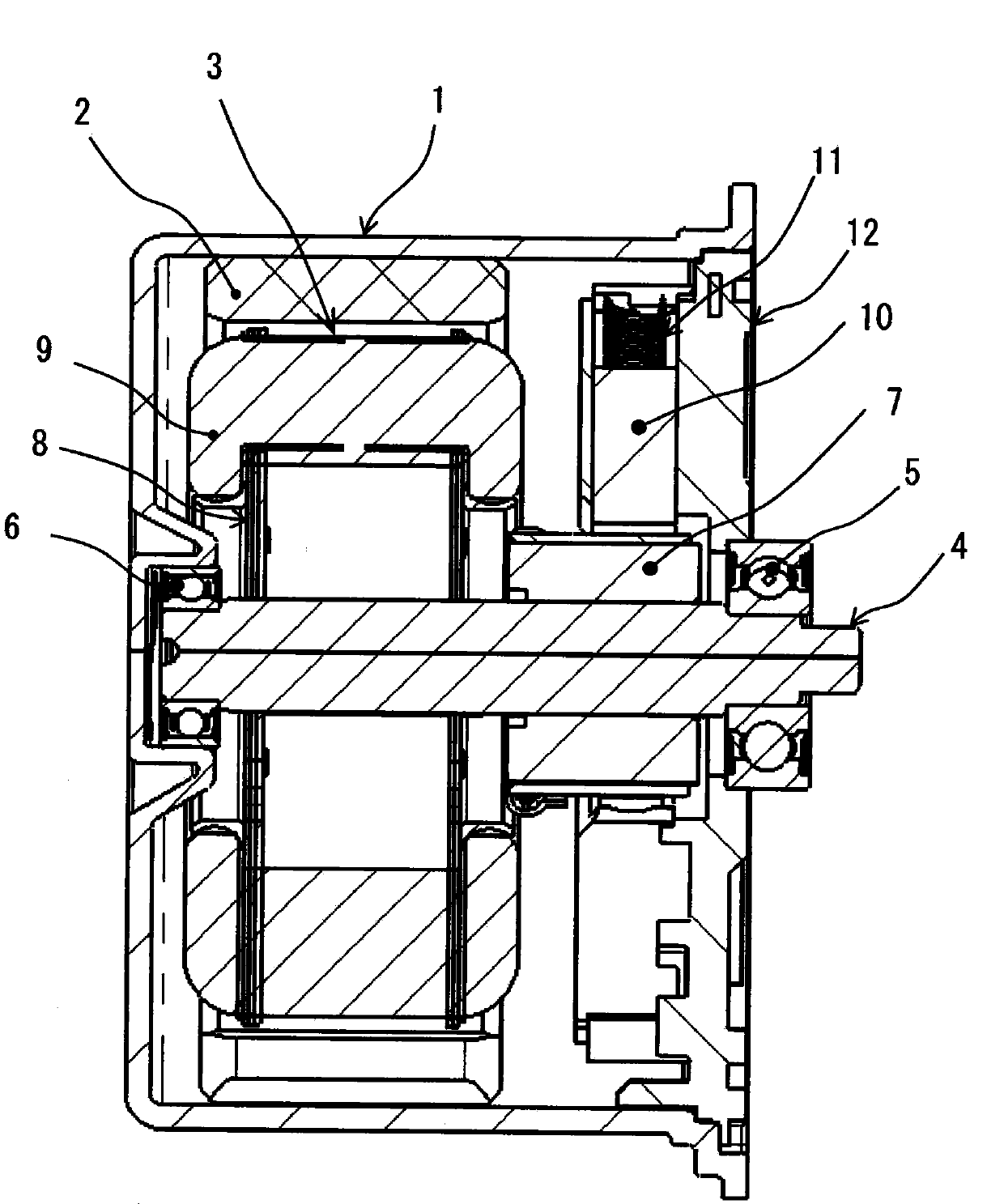

[0049] figure 1 It is a cross-sectional view of the brushed DC motor of the present invention viewed from the side. In the brushed DC motor mechanism, the armature 3 is disposed on the inner circumference of the yoke 1 and the field magnet 2 .

[0050] The armature 3 includes a shaft 4 and is supported by an output shaft side bearing 5 and an output shaft opposite side bearing 6 provided at the shaft center of the brushed DC motor. In addition, the output shaft side bearing 5 is held by the brush holder plate 12 , and the brush holder plate 12 is held by the yoke 1 . Next, a commutator 7 and an armature core 8 are provided on the shaft 4 , and a coil 9 is wound around the slots of the armature core 8 . Both ends of the coil 9 are connected to segments constituting the commutator 7 .

[0051] When a voltage is applied to the brushed DC motor, current flows through the brushes 10 held by the brush hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com