Modified montmorillonite and preparation method as well as application thereof in water resource purification

A montmorillonite and modified technology, applied in other chemical processes, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of the limitation of adsorbable metal ions, and achieve the goal of improving selective adsorption defects and improving the degree of purification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

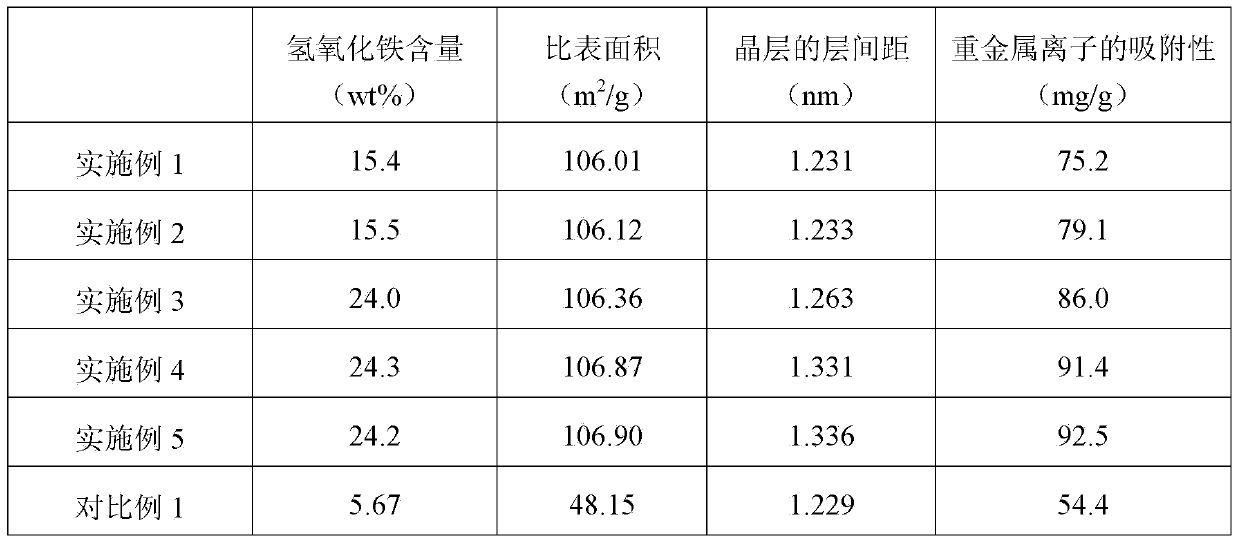

[0020] As introduced in the background technology section, when using montmorillonite to purify water sources, there is a problem that the adsorbable metal ions are relatively limited. In order to solve this problem, the inventors of the present invention provide a preparation method of modified montmorillonite. The method comprises the following steps: S1, adding montmorillonite to the first solution to form a suspension to be columnized; S2, adding the second solution to the suspension to be columnized, stirring and reacting, and filtering to obtain the modified Montmorillonite; wherein, the first solution is an aqueous solution of sodium hydroxide, and the second solution is an aqueous solution of ferric chloride; or the first solution is an aqueous solution of ferric chloride, and the second solution is an aqueous solution of sodium hydroxide.

[0021] In the above method provided by the present invention, the ferric hydroxide pillaring agent is introduced between the crys...

Embodiment 1

[0037] At a temperature of 30°C, disperse 10g of montmorillonite into 200ml of 0.005mol / L FeCl 3 In an aqueous solution, a suspension to be columnized is formed;

[0038] Add 300ml, 0.005mol / L NaOH aqueous solution dropwise at a flow rate of 0.6ml / min to the suspension to be columned, and keep stirring during the addition. After the titration is completed, after reacting for 2 hours, filter with suction, dry at 70° C. for 24 hours, and grind to below 200 mesh to obtain modified montmorillonite.

Embodiment 2

[0040] Weigh 10g of montmorillonite and disperse it into 200ml of 0.05mol / L NaOH aqueous solution, and stir at 70°C for 3h. Cooling, suction filtration, washing with deionized water twice, drying to obtain pretreated montmorillonite;

[0041] At a temperature of 30°C, disperse the above pretreated montmorillonite into 200ml, 0.005mol / L FeCl 3 In an aqueous solution, a suspension to be columnized is formed;

[0042] Add 300 ml, 0.005 mol / L NaOH aqueous solution dropwise at a flow rate of 3.5 ml / min to the suspension to be columned, and keep stirring during the addition. After the titration was completed, after 2 hours of reaction, suction filtration was performed. Wash twice with suction filtration of hydrochloric acid with a concentration of 0.02mol / L, and then wash three times with deionized water. Then it was placed in 50ml of hydrogen peroxide / water solution with a concentration of 12wt%, stirred for 1h and then suction filtered. Dry at 70°C for 24 hours, and grind to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap