A welding method for a medium frequency inverter resistance welding machine

A technology of resistance welding machine and welding method, which is applied in the direction of resistance welding equipment, welding power supply, welding equipment, etc., which can solve the problems of solder joint virtual welding, large volume of welding transformer, low sampling frequency and control precision, and achieve volume reduction , Sampling frequency and control accuracy are improved, and the effect of avoiding virtual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

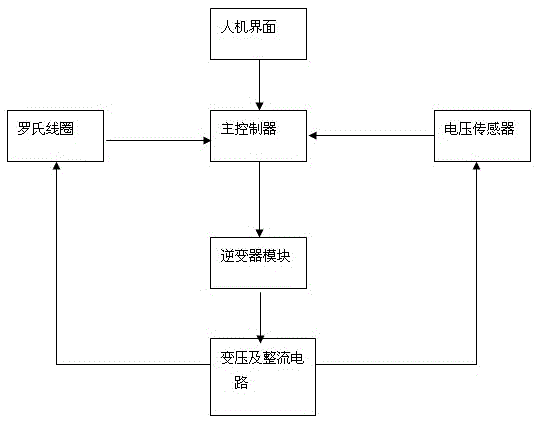

[0016] Such as figure 1 As shown, the intermediate frequency inverter resistance welding machine includes a human-machine interface, a main controller, an inverter module, a voltage transformation and rectification circuit, a current acquisition device and a voltage sensor; the current acquisition device can be selected from Rogowski coils, and the The transformer in the transformer and rectifier circuit can be a welding transformer, the man-machine interface can transmit preset parameters to the main controller, and the inverter module converts direct current into alternating current and transmits it to the transformer and rectifier circuit. The voltage transformation and rectification circuit transforms and rectifies the alternating current converted by the inverter module into direct current for welding by the welding machine. to the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com