Teflon aluminum strip

A technology of Teflon aluminum and Teflon, applied in the direction of slender components, building components, etc., can solve the problems of poor mechanical strength, fatigue fracture, easy accumulation of scale or oil on the surface, etc., achieve long service life, increase mechanical The effect of strength and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

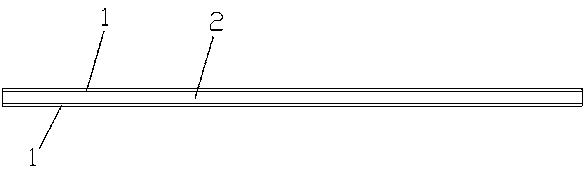

[0013] see figure 1 , the embodiment of the present invention includes:

[0014] A Teflon aluminum strip, comprising an aluminum strip 2, the upper and lower surfaces of the aluminum strip 2 are coated with a Teflon coating 1, and the Teflon coating 1 is made of polytetrafluoroethylene and wear-resistant It is made by mixing anti-wear agent, and the anti-wear agent is polyimide.

[0015] Preferably, the weight percentage of the polyimide in the Teflon coating layer 1 is 8%-10%.

[0016] Preferably, the cross-secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap