Controlling method of numerical control jig frame for ship building

A control method and tire frame technology, which is applied to ship parts, ship construction, and electrical digital data processing, etc., can solve problems such as limited adjustment accuracy of the tire frame value, unautomated general tire frame, and discontinuous height adjustment, etc., to achieve The effect of shortening the shipbuilding period, convenient adjustment, and high control and adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

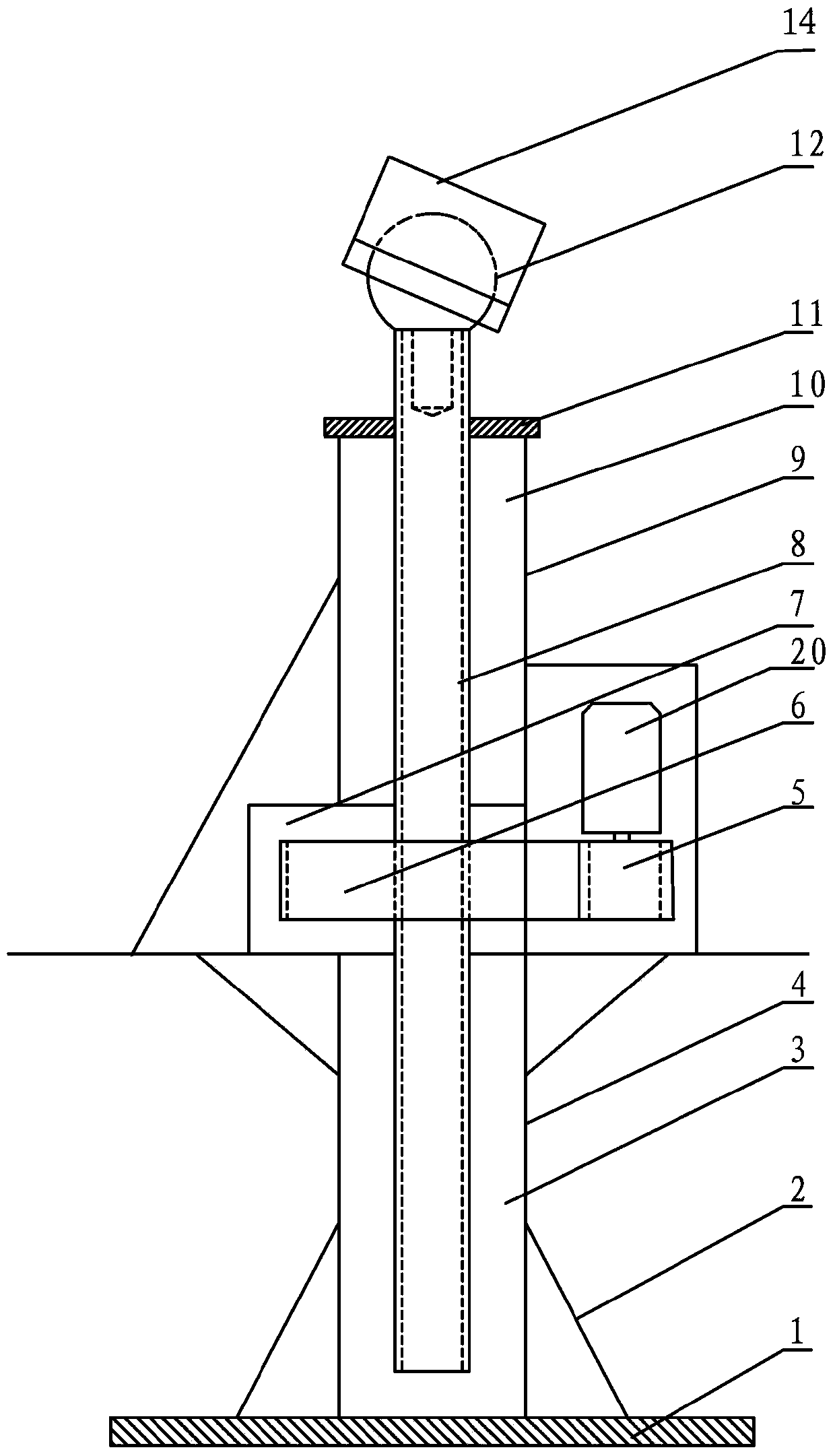

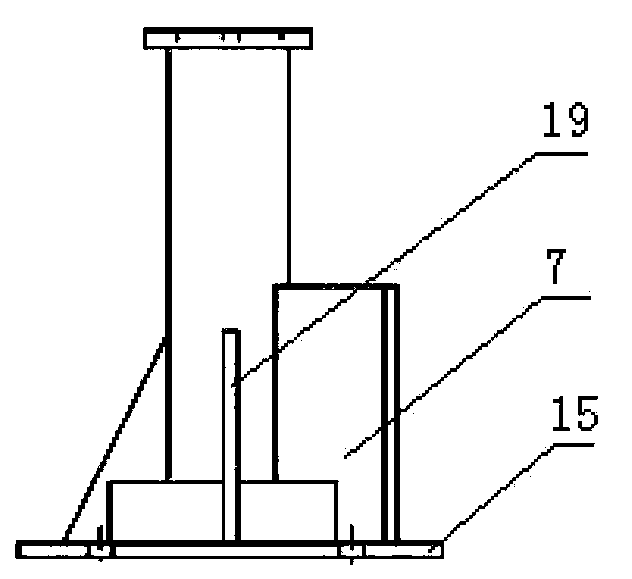

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

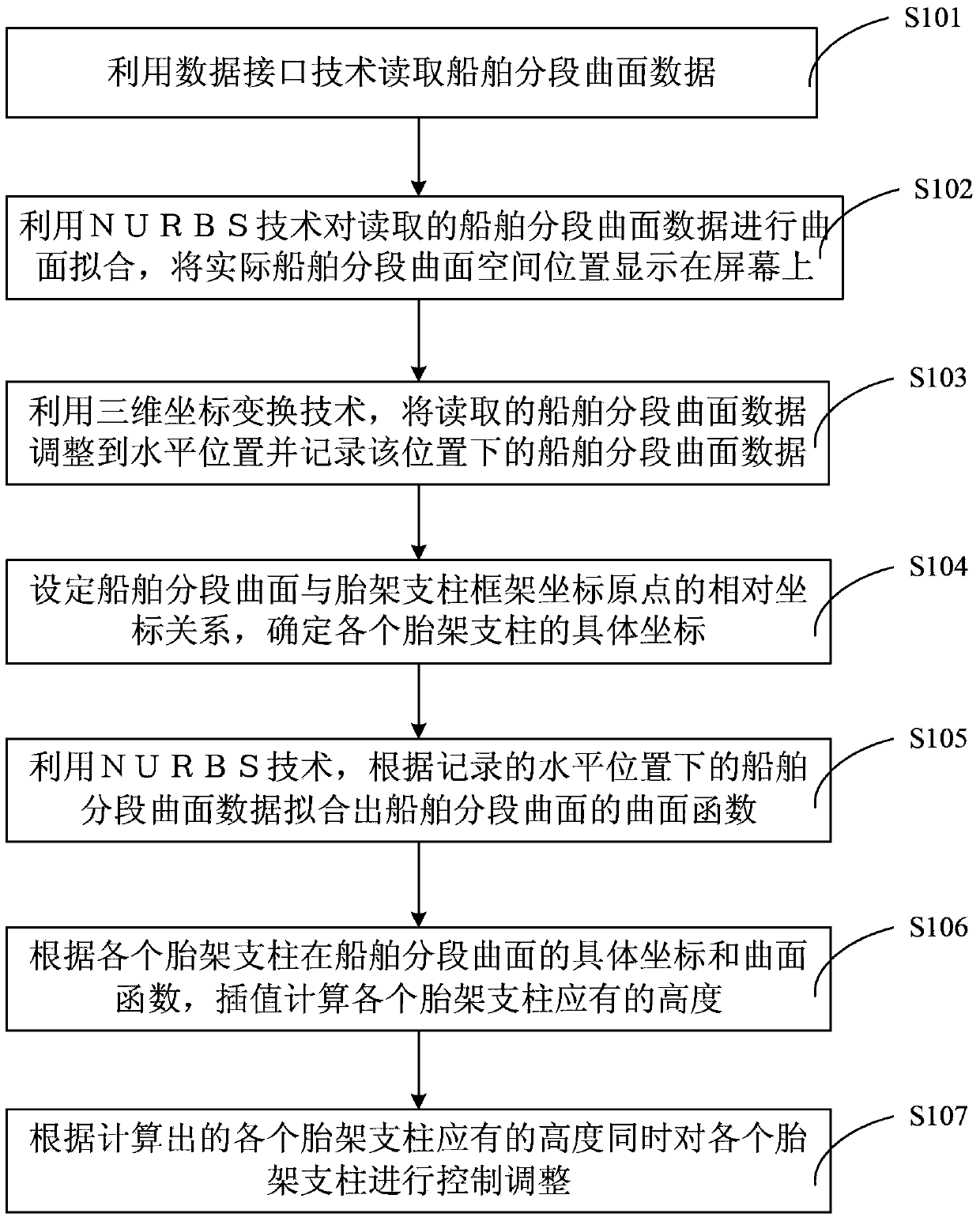

[0027] figure 1 Shown is the flow chart of the numerically controlled tire frame control method for shipbuilding of the present invention, which includes:

[0028] S101. Using the data interface technology to read the segmented surface data of the ship;

[0029] Using the data interface technology, it can interface with the ship segment data files directly output from the digital shipbuilding system widely used by shipyards, and directly read the model value data of the ship segment from these files, and apply it to the ship segment surface generate;

[0030] S102. Use NURBS technology to perform surface fitting on the read ship segmented surface data, and display the actual space position of the ship segmented surface on the screen;

[0031] In this step, NURBS technology is used to obtain the control points and control coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com