Lifting and turning machine

A technology of turning machine and turning mechanism, which is applied in the field of conveying machinery, can solve the problems of unstable performance of turning hoist, high maintenance cost, and cannot be solved quickly, so as to improve operability, simple operation and maintenance, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

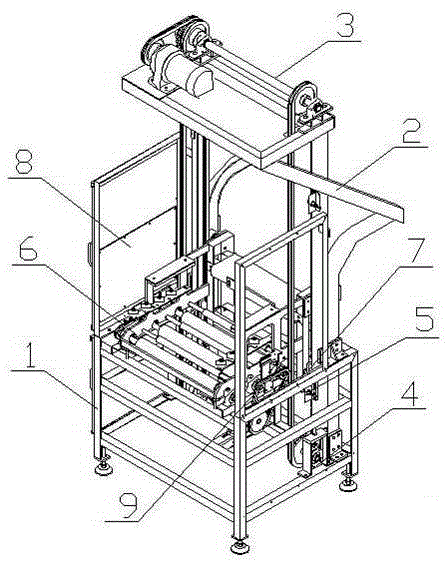

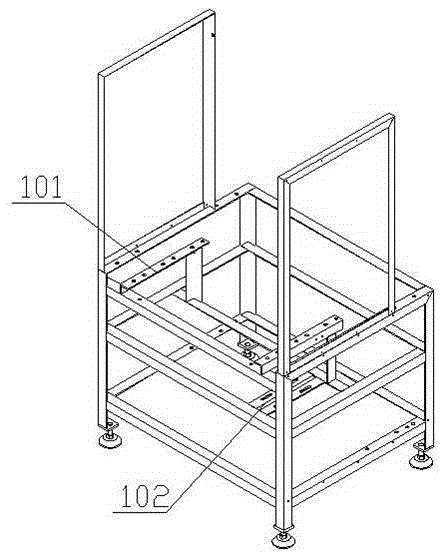

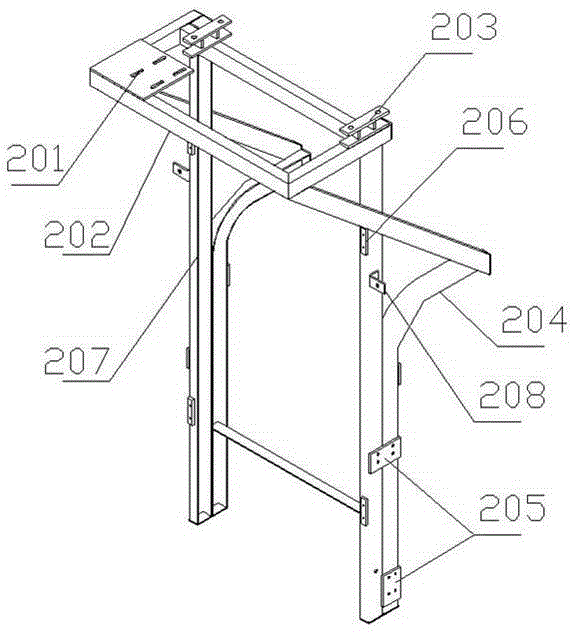

[0025] Such as Figure 1-Figure 9 As shown, the lifting and turning machine includes a main body 1, a sliding guide rail 2, a chain lifting mechanism 3, a chain tensioning mechanism 4, a photoelectric detection mechanism 5, a lifting and turning mechanism 6, a nylon roller guide mechanism 7 and a two-way conveying mechanism 9 A lifting and turning mechanism 6 and a bidirectional conveying mechanism 9 are installed in the middle of the main body 1 of the fuselage. The lifting and turning mechanism 6 is located above the bidirectional conveying mechanism 9, and the nylon roller guide mechanism 7 is hingedly mounted on the lifting and turning mechanism 6. A chain tensioning mechanism 4 is installed at the lower part of the main body 1, a photoelectric detection mechanism 5 is installed on both sides of the main body 1, and a sliding guide rail 2 is installed at the rear of the main body 1. The upper part of the chain lifting mechanism 3 is installed on the sliding guide rail 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com