Colloid titanium surface conditioner and preparation method thereof

A technology of surface modifier and gel titanium, which is applied in the coating process of metal materials, etc., can solve the problems of large investment in phosphating equipment, coarse crystallization of phosphating film, and high environmental protection pressure, so as to shorten the phosphating time and strengthen anti-rust Spot function, reduce the effect of phosphating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

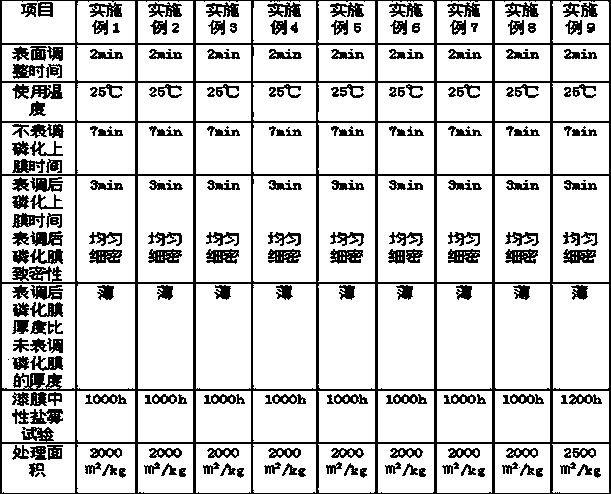

Examples

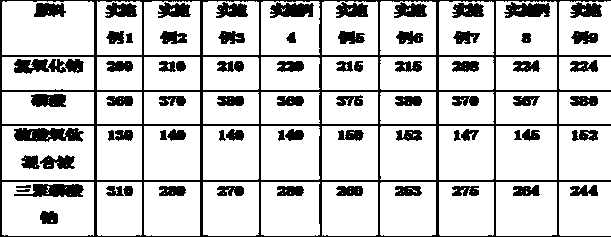

Embodiment 1

[0031] Every 1000Kg gel titanium surface conditioner is made of the following raw materials:

[0032] Sodium hydroxide 200Kg, phosphoric acid 360 Kg, titanyl sulfate mixed solution 130 Kg, sodium tripolyphosphate 310 Kg.

[0033] The titanyl sulfate mixed solution is a solution of titanyl sulfate: water = 1:2 (the titanyl sulfate mixed solution is used in the following examples).

[0034] Its preparation method comprises the following steps in turn:

[0035] (1) Add titanyl sulfate mixture to the reaction kettle;

[0036] (2) Add sodium hydroxide to the reaction kettle and stir for 3-10 minutes until the sodium hydroxide is completely dissolved;

[0037] (3) Slowly add phosphoric acid to the reactor until the reaction is complete, and the dropping time is 1-3 hours;

[0038] (4) Add sodium tripolyphosphate into the reaction kettle, stir evenly, and the stirring time is 1-3 hours;

[0039] (5) The physical and chemical indicators of the product are tested, and the product i...

Embodiment 2

[0043] Every 1000Kg gel titanium surface conditioner is made of the following raw materials:

[0044] Sodium hydroxide 210Kg, phosphoric acid 370Kg, titanyl sulfate mixed solution 140Kg, sodium tripolyphosphate 280Kg.

[0045] The preparation method and usage method are the same as in Example 1.

[0046]

Embodiment 3

[0048] Every 1000Kg gel titanium surface conditioner is made of the following raw materials:

[0049] Sodium hydroxide 210Kg, phosphoric acid 380Kg, titanyl sulfate mixed solution 140Kg, sodium tripolyphosphate 270Kg.

[0050] The preparation method and usage method are the same as in Example 1.

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com