Through-flow water turbine with front and rear symmetrical constant-width movable guide blades

A technology of tubular water turbine and movable guide vanes, which is applied to engine components, machines/engines, reaction engines, etc., can solve the problems of poor hydraulic performance of reverse power generation, affecting reverse power generation efficiency, and reducing forward power generation efficiency. , to achieve the effect of improving power generation efficiency, improving reverse power generation efficiency and reducing hydraulic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

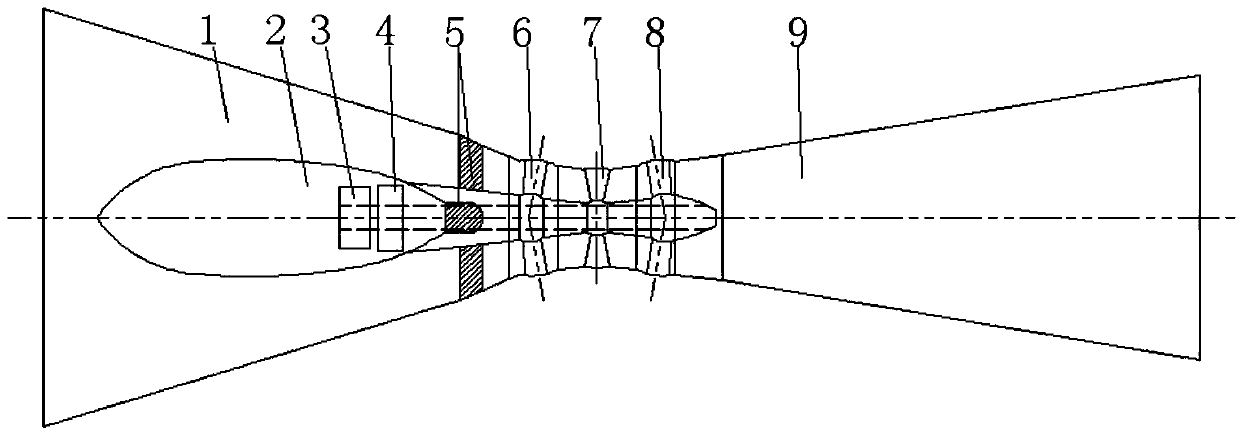

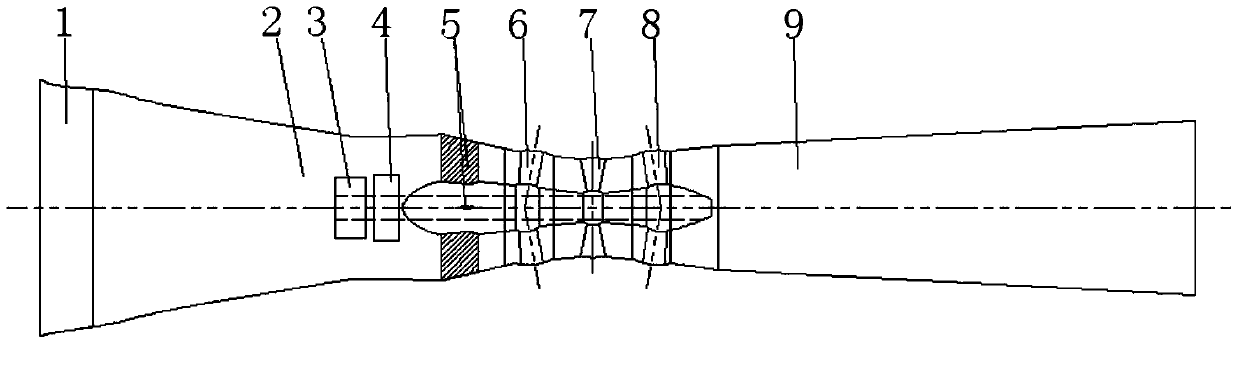

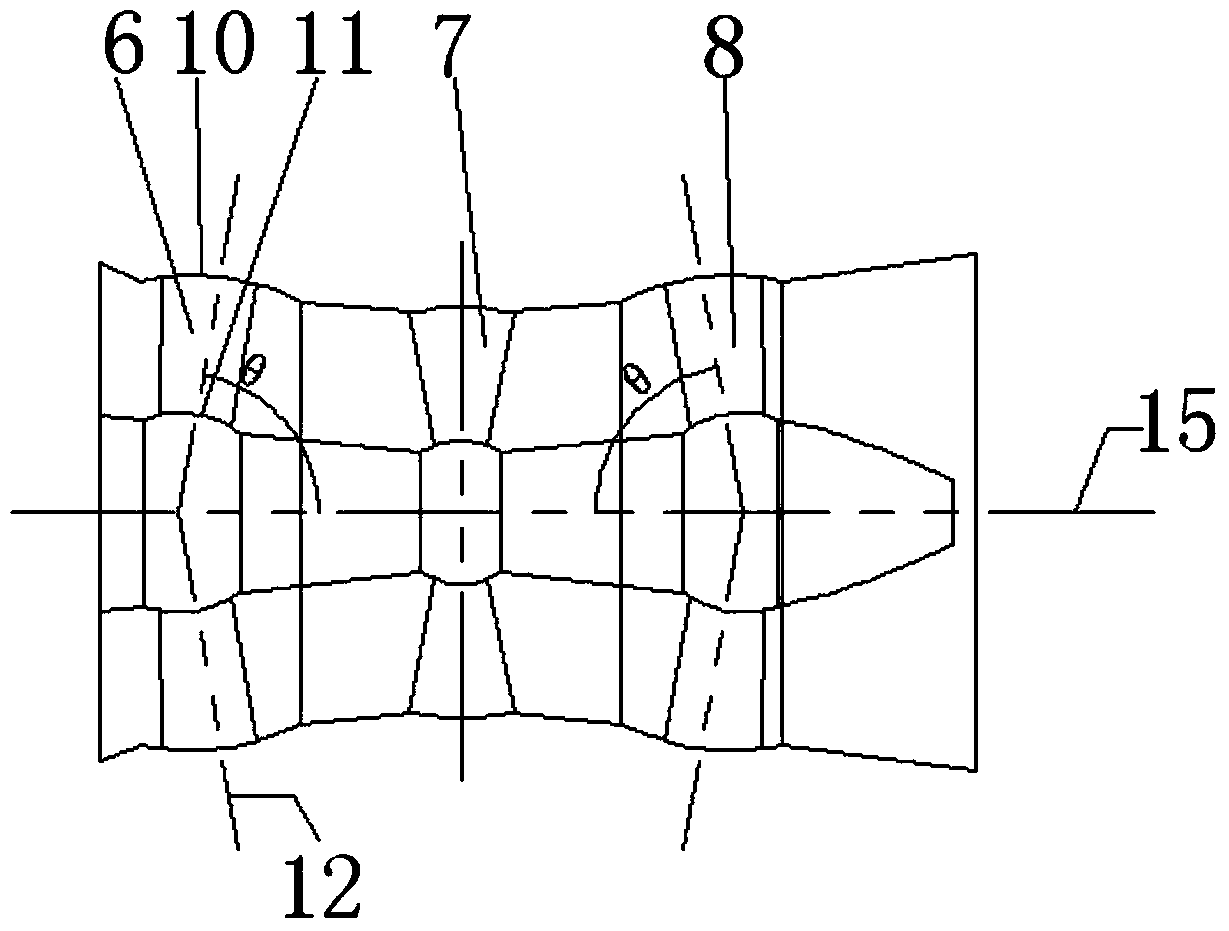

[0028] combine figure 1 , figure 2 and Figure 4 , the present invention proposes a tubular water turbine with front and rear symmetrical and equal-width movable guide vanes, which includes a forward water inlet channel (1), a vertical shaft (2), a support frame (5), a two-way power generation runner (7 ), the reverse water inlet flow channel (9), the generator (3) and the speed increaser (4), the generator (3) is connected with the two-way generating runner (7) through the speed increaser (4); the generator (3) and the speed increaser (4) are placed in the vertical shaft (2); among them: it also includes the front equal width movable guide vane (6) and the rear equal width movable guide vane (8), the front equal width movable guide vane The guide vane (6) is set between the forward water inlet channel (1) and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com