General pneumatic control rifle bolt mechanism

A bolt and gas technology, applied in the firing/trigger mechanism, weapon accessories, offensive equipment, etc., can solve the problems of increasing weight, difficult to simplify the structure, etc., and achieve the effect of solving potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] When the bolt is pushed, it is held up by the drooping bolt lock iron and cannot move forward, making it in an insecure state ( Figure 5 ).

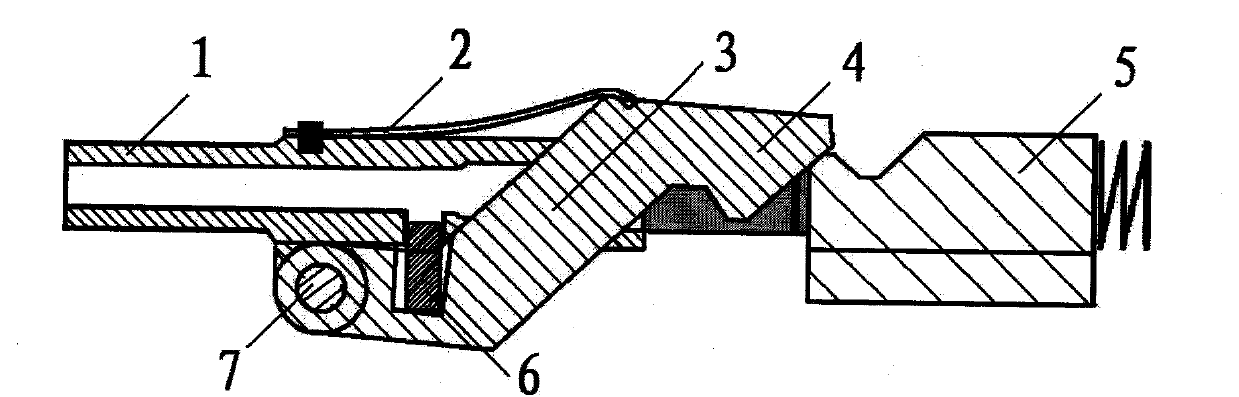

[0031] Drive the trigger lever, when the safety state is released, the bolt will be pushed into the bolt lock ( figure 1 ), and buckle with the lock arm clamp along the V-shaped contact surface. At this time, the bolt is pushed into place, and the firing pin protrudes to fire the bullet ( figure 2 ).

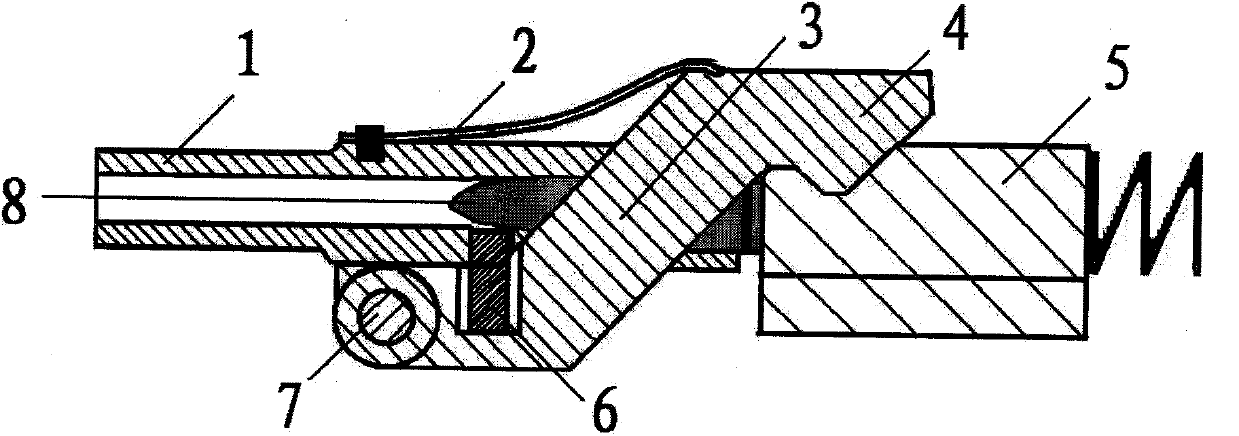

[0032] When the gunpowder gas pushes the warhead over the small hole at the rear of the barrel, the gas force exerts a pressure on the lock arm through the piston in the hole, so that the iron end of the lock arm clamps the bolt along the V-shaped contact surface to form a lock ( image 3 ).

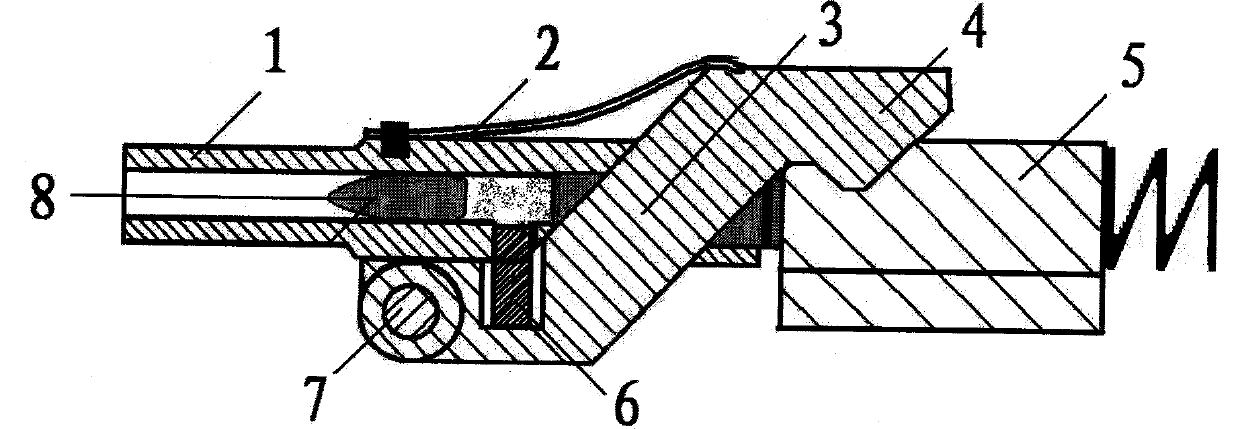

[0033] When the bullet is pushed out of the barrel, the pressure in the barrel decreases, the force of the piston on the iron end of the machine lock decreases accordingly, and when the force is not enough to offset the recoil force on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com