A Method for Detecting Transformer Winding Deformation

A technology for transformer windings and transformers, which is applied in the measurement of electrical variables, instruments, and electrical measurement, can solve problems such as poor anti-interference, unclear criteria, and undiagnosed results, and achieve high accuracy and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

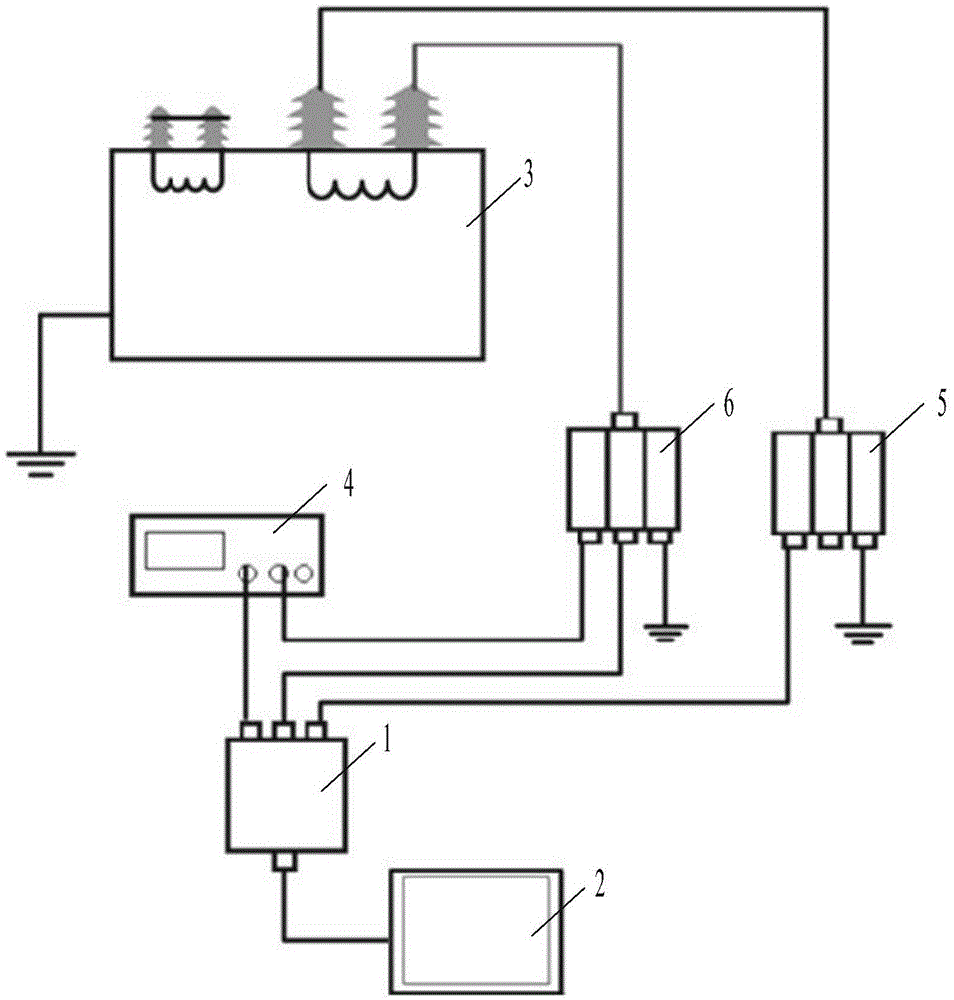

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

[0023] refer to figure 1 , the system for detecting transformer winding deformation of the present invention includes a controller 2, an HS3 multifunctional signal generator 1, a power amplifier 4, a first sampling resistor 5, a second sampling resistor 6 and a test transformer 3; the HS3 multifunctional The input terminal of the functional signal generator 1 is respectively connected with the output terminal of the controller 2, the output terminal of the power amplifier 4 and the end of the winding in the test transformer 3, and the output terminal of the HS3 multifunctional signal generator 1 is connected with the terminal of the controller 2 respectively. Input end, the input end of power amplifier 4 are connected, and the output end of power amplifier 4 is connected with the start end of winding in test transformer 3; The first sampling resistor 5 is connected, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com