Backlight module and display device

A backlight module and high-beam technology, applied in light guides, optics, optical components, etc., can solve problems such as reducing the utilization rate of light energy, achieve the effects of improving light leakage, reducing loss of light energy, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a backlight module, including a light guide plate and a plastic frame located around the light guide plate, the light guide plate includes a light incident surface and a high beam surface opposite to the light incident surface, the plastic frame It includes a first frame opposite to the far light surface of the light guide plate, the first frame includes a first surface opposite to the far light surface of the light guide plate, wherein the first surface has a first microstructure, The first microstructure is used to reflect light incident on the first microstructure to various directions.

[0027] In this embodiment, by setting a first microstructure on the first surface of the first frame of the plastic frame, the first microstructure can scatter the relatively concentrated light incident on the surface, so that the light can be reflected in different directions, Therefore, bright lines will not be formed on the far light side of the light gui...

Embodiment 2

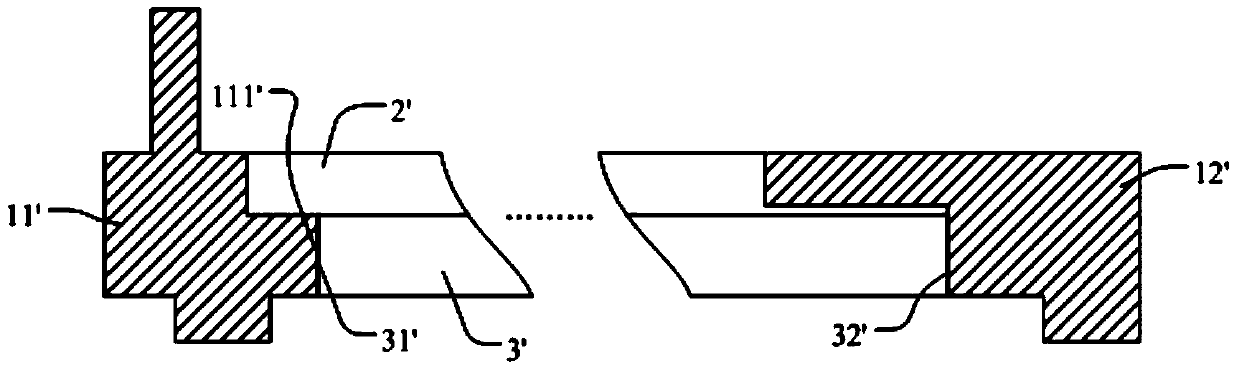

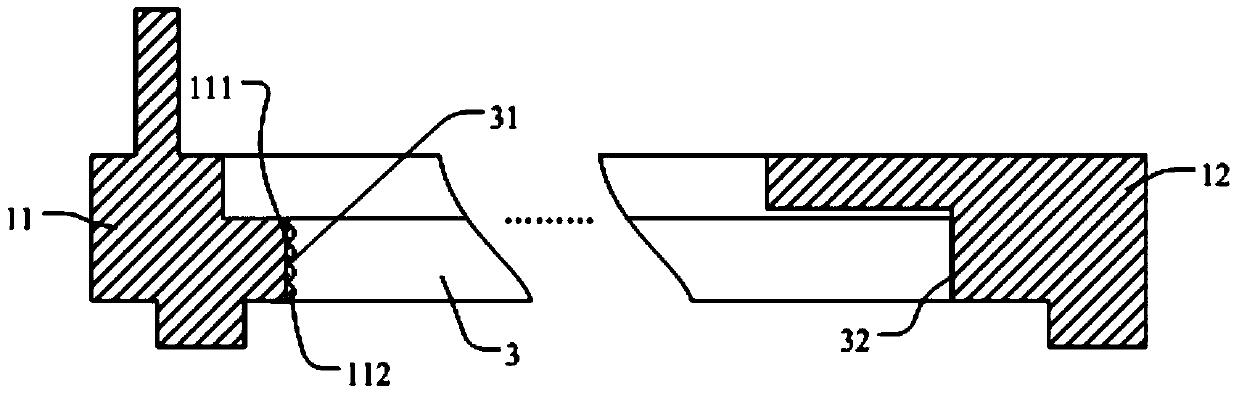

[0029] figure 2 It is a schematic diagram of a backlight module provided in this embodiment. The backlight module includes a light guide plate 3 and a plastic frame located around the light guide plate. The light guide plate 3 includes a light incident surface 32 and a far side opposite to the light incident surface 32 Optical surface 31, the plastic frame includes a first frame 11 opposite to the high beam surface 31 and a second frame 12 opposite to the light incident surface 32, wherein the first frame 11 includes a frame opposite to the high beam surface 31 of the light guide plate The first surface 111 , wherein the first surface 111 has a first microstructure, and the first microstructure is used to reflect light incident on the first microstructure to various directions. Specifically, when the light in the light guide plate is incident on the first surface from the high beam surface 31, it will be chaotically reflected in various directions by the first microstructures...

Embodiment 3

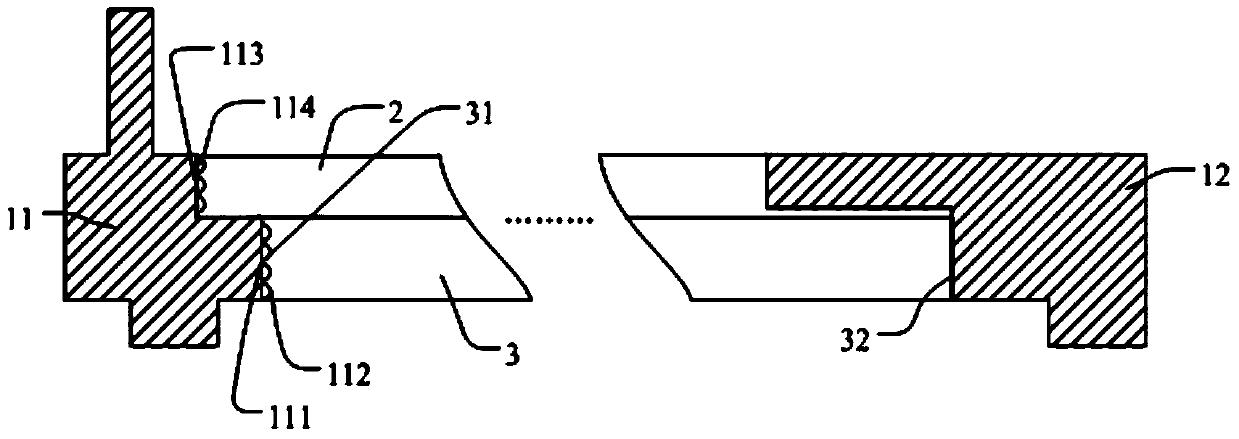

[0032] see image 3 , image 3 It is a schematic diagram of a backlight module provided in this embodiment. The backlight module includes a light guide plate 3 and a plastic frame located around the light guide plate. The light guide plate 3 includes a light incident surface 32 and a far side opposite to the light incident surface 32 Optical surface 31, the plastic frame includes a first frame 11 opposite to the high beam surface 31 and a second frame 12 opposite to the light incident surface 32, wherein the first frame 11 includes a frame opposite to the high beam surface 31 of the light guide plate The first surface 111, the first surface 111 has a first microstructure, and the first microstructure is used to reflect the light incident on the first microstructure to various directions, and the backlight module also includes a The optical film material 2 above the light guide plate, wherein the first frame 11 also includes a second surface 113 opposite to the optical film ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com