Machine vision-based building structure crack detection and repair method

A technology of building structure and repair method, which is applied in the direction of instruments, optical testing flaws/defects, image data processing, etc., can solve problems affecting the reliability of results, non-real-time information, noise influence, etc., to promote intelligent development and improve The effect of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

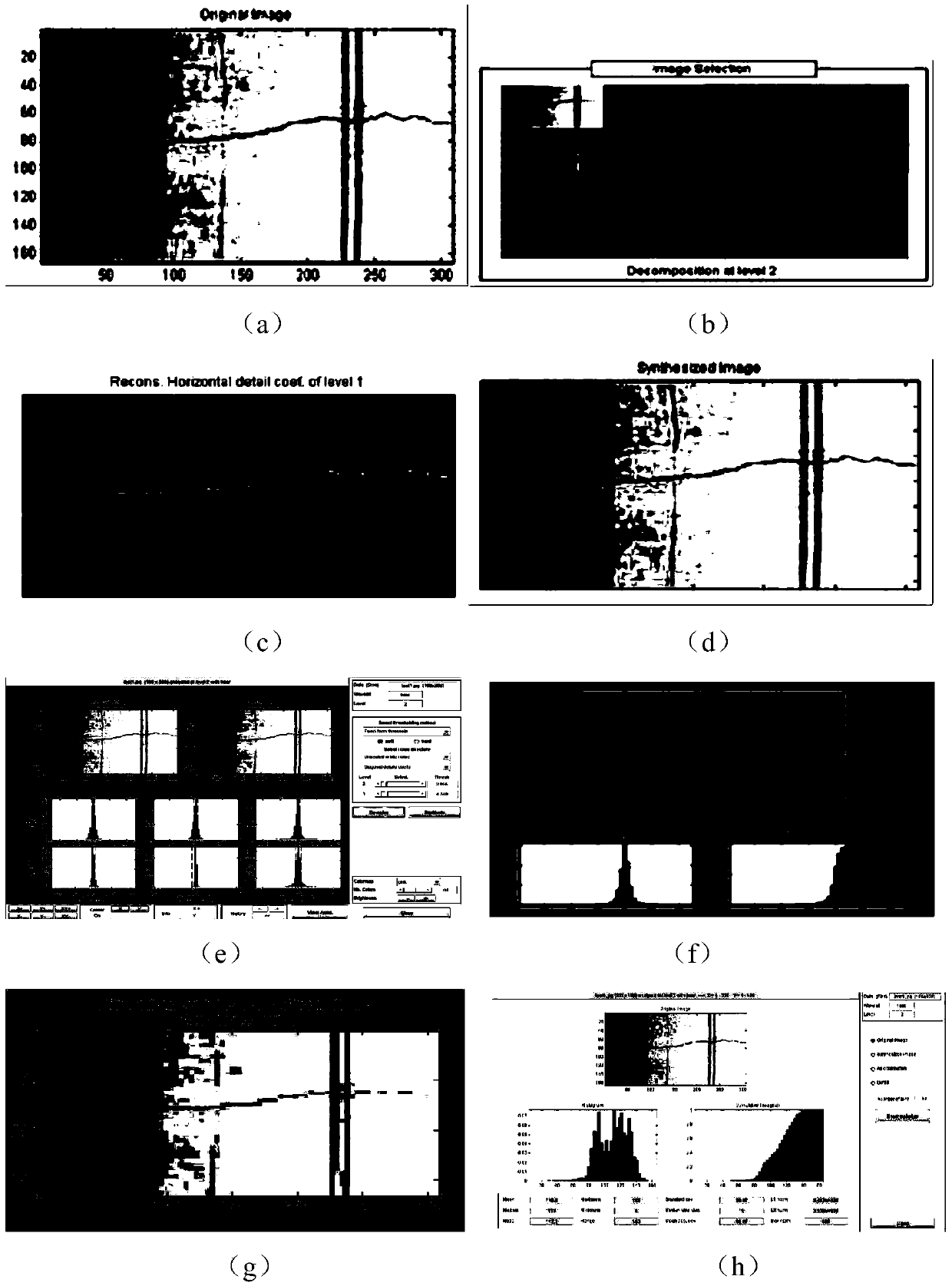

[0035] like figure 1 As shown, (a) is the original image of cracks in the building, (b) is the result obtained after decomposing the original image using Harr transform, and (c) is an image after decomposing. It can be seen that the wavelet transform processing Finally, the wires in the original image can be removed, leaving only the cracks (vertical lines in the figure), (d) is the combined image after decomposing the picture, (e) is obtained after removing noise by wavelet transform Image, (f) is the difference between the denoised image and the original image, (g) is the original image compressed by wavelet, (g) is the quantitative analysis of the image.

[0036] It can be seen from the above that using wavelet transform technology can obtain more accurate fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com