Whole-process real-time intelligent tracking and demonstration platform for Internet of things based product supply chain

A demonstration platform and real-time tracking technology, applied in the field of education or demonstration equipment, can solve the problems of ignoring the Internet of Things, the stage of one-sided understanding of the Internet of Things, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

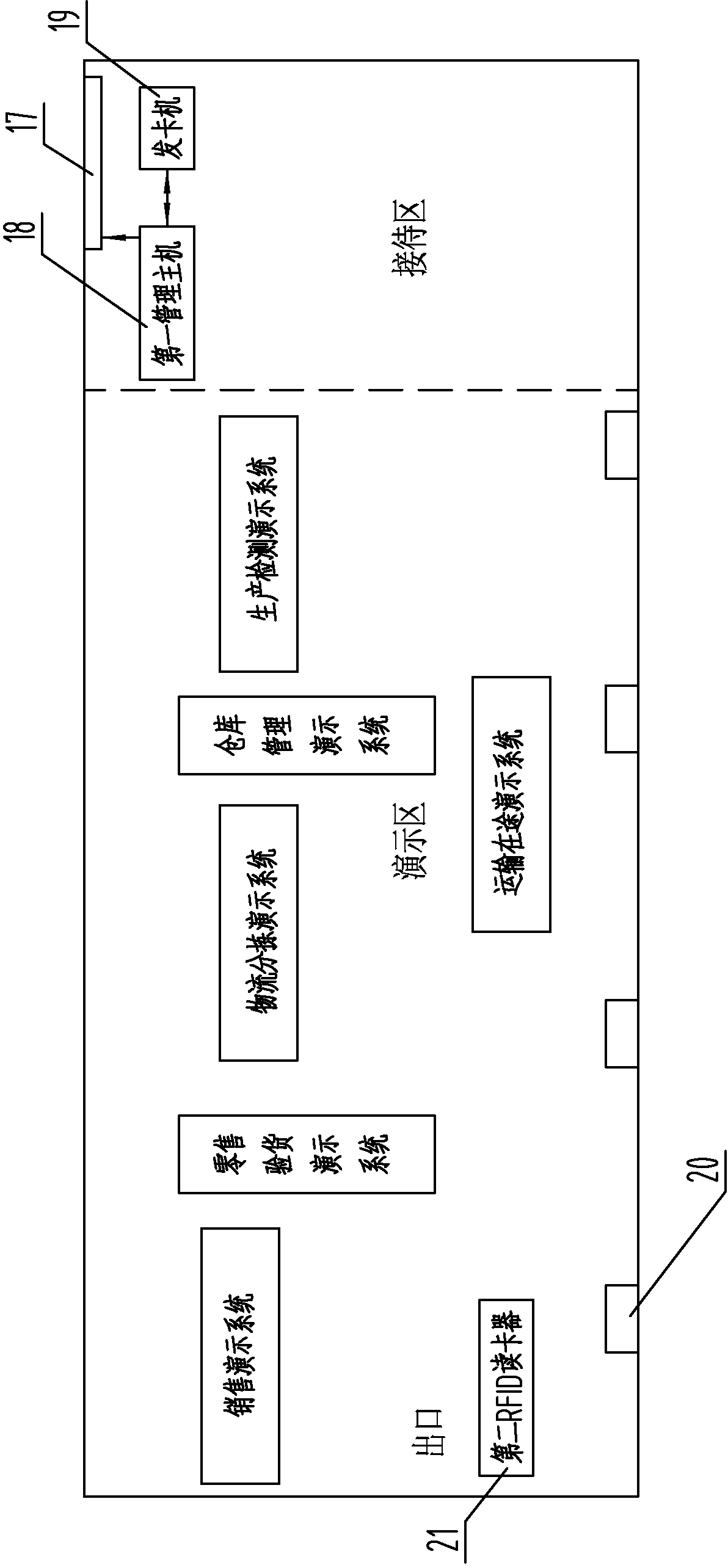

[0051] like figure 1 As shown, the present invention sets a first management host 18 and an electronic display screen 17 connected to the first management host 18 in the reception area. The first management host 18 can access the Internet or run the image data stored in its own hard disk, And displayed on the electronic display screen 17; before entering the demonstration area, the visitors watch the video related to the Internet of Things through the electronic display screen 17, giving the visitors a preliminary understanding, in order to enter the demonstration area to watch the specific demonstration of each system Do the foreshadowing.

[0052] The reception area is also equipped with a plurality of RFID cards and a card issuing machine 19. The card issuing machine 19 is connected to the first management host 18. The first managem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com