Storage battery internalizing device with full-automatic cooling system

A cooling system and internalization technology, applied in the direction of lead-acid batteries, lead-acid battery construction, battery pack components, etc., can solve the problems of battery dendrite short-circuit plate additives, battery performance degradation, and increase in non-conforming products, etc., to achieve Simple structure, good quality, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

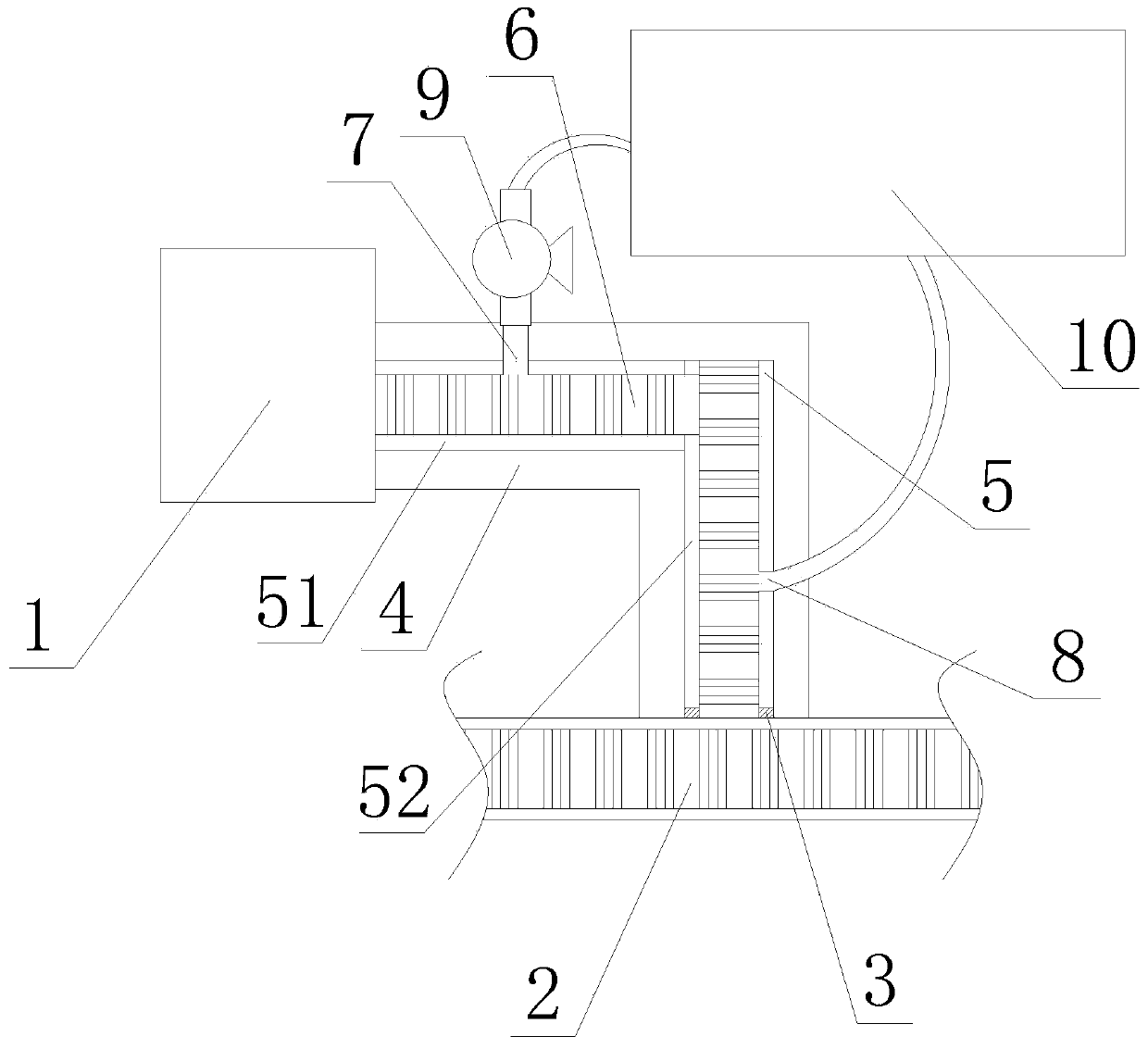

[0013] refer to figure 1 , the present invention includes a battery acid adding device 1 and an internalized conveyor belt 2, the internalized conveyor belt 2 is connected with a cooling system, the cooling system includes a frame 4 and a water tank 5, and the water tank 5 is fixed on On the frame 4, the bottom of the water tank 5 is provided with a conveyor belt 6, and the water tank 5 is provided with a water inlet 7 and a water outlet 8, and the water inlet 7 and the water outlet 8 are connected to the cooling water tank 10 through a water pump 9, The water tank 5 includes a first water tank 51 and a second water tank 52, the first water tank 51 is connected to the second water tank 52, the opening of the first water tank 51 is connected to the discharge port of the battery acid adding device 1, and the opening of the second water tank 52 The outlet is connected to the internalization conveyor belt 2, and the outlet of the second water tank 52 is provided with an infrared m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com