A variable friction cable pay-off

A wire pay-off and friction technology, applied in cable laying equipment and other directions, can solve the problems of slow extraction speed, cables falling on the ground next to them, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

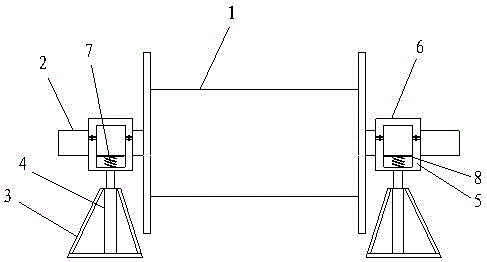

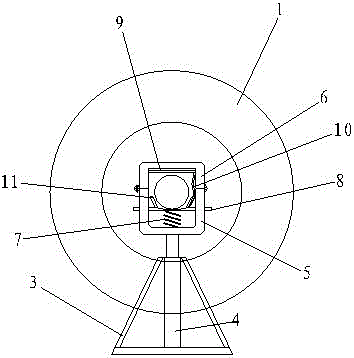

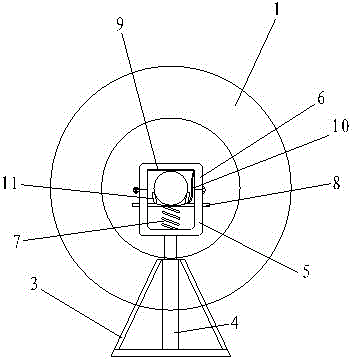

[0019] Embodiment one: if figure 1 As shown, a variable friction cable pay-off device includes two bases 3, a pay-off shaft 2 that rotates synchronously with the cable reel 1, and a brake mechanism. A jack 4 is installed on the base 3, and the jack 4 4 is equipped with a wire release trough, which includes a lower tank body 5 and an upper tank cover 6, a spring 7 is arranged in the lower tank body 5, and a The moving steel plate 8, the two ends of the pay-off shaft 2 are placed on the steel plate 8.

[0020] In this example, if Figure 5 As shown, the brake mechanism includes a brake pad 11 arranged on the steel plate 8 and a brake handle 9 arranged on the inner top of the upper tank cover 6, the brake pad 11 is arranged on both sides of the pay-off shaft 2, and the brake handle 9 The tightness of the brake pads 11 is controlled by the brake line 10 .

[0021] In this example, if Figure 4 As shown, both sides of the spring 7 are provided with protrusions 501 to prevent th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com