An electric self-propelled seedling harvester

A self-propelled, harvester technology, used in harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of increased labor intensity, large resistance to pushing the machine, and large oil and gas pollution, and achieves reduced labor intensity. Small effect, quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

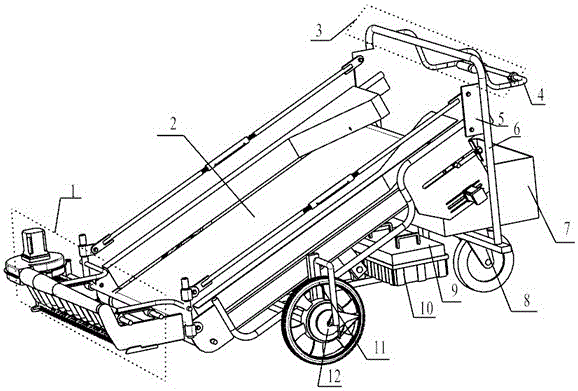

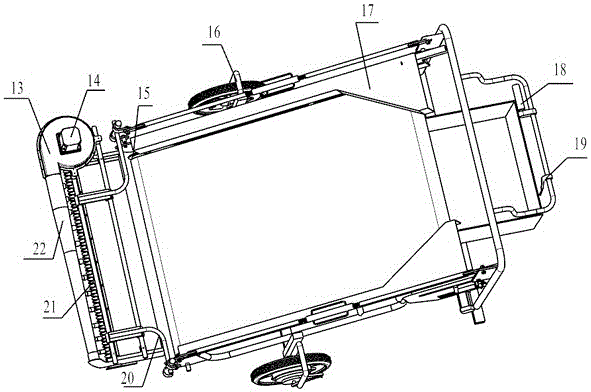

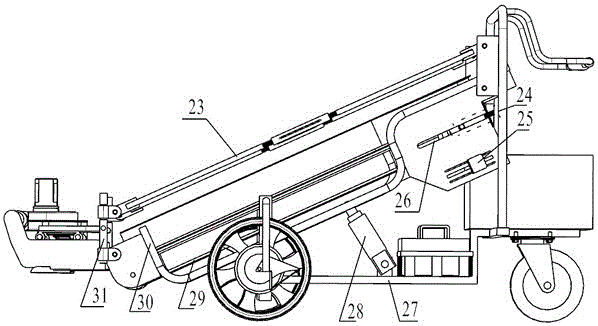

[0024] Such as Figures 1 to 6 Shown, a kind of electric self-propelled seedling grass harvester comprises vehicle frame 27, walking device, cutting device 1, inclined conveying device 2, electric push rod 28, collection box 7, handrail assembly 3, lithium battery 9 and battery Box 10, the handrail assembly 3 includes a handrail column 6 and a handrail 4, the cutting device 1 is located at the front of the vehicle frame 27, the cutting device 1 is fixedly connected to the inclined conveying device 2 through the cutting device connector 20, and the inclined conveying device 2. It is fixedly connected with the armrest column 6, and the armrest column 6 is fixedly connected to the upper rear end of the vehicle frame 27, and the collection box 7 is placed at the upper rear end of the vehicle frame 27; the battery box 10 is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com