Electronic cigarette, manufacturing method and liquid injection method

An electronic cigarette and liquid injection technology, which is applied in the fields of tobacco, smokers’ supplies, applications, etc., can solve the problems of inconvenient automatic liquid injection production, leakage, smoke liquid pollution, etc., and achieve fast welding speed, easy operation and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with accompanying drawing:

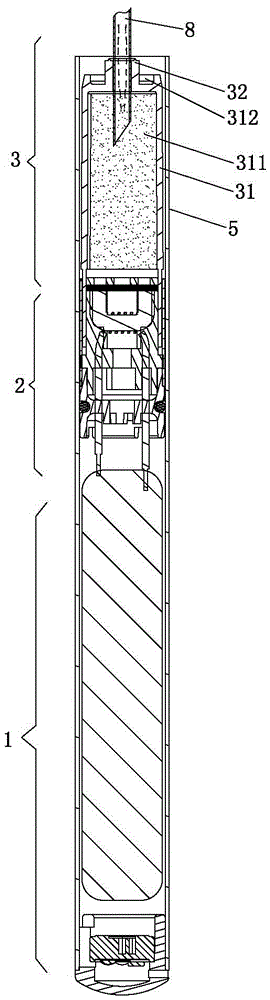

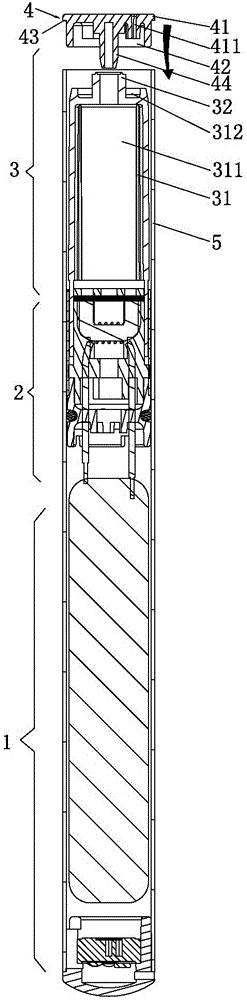

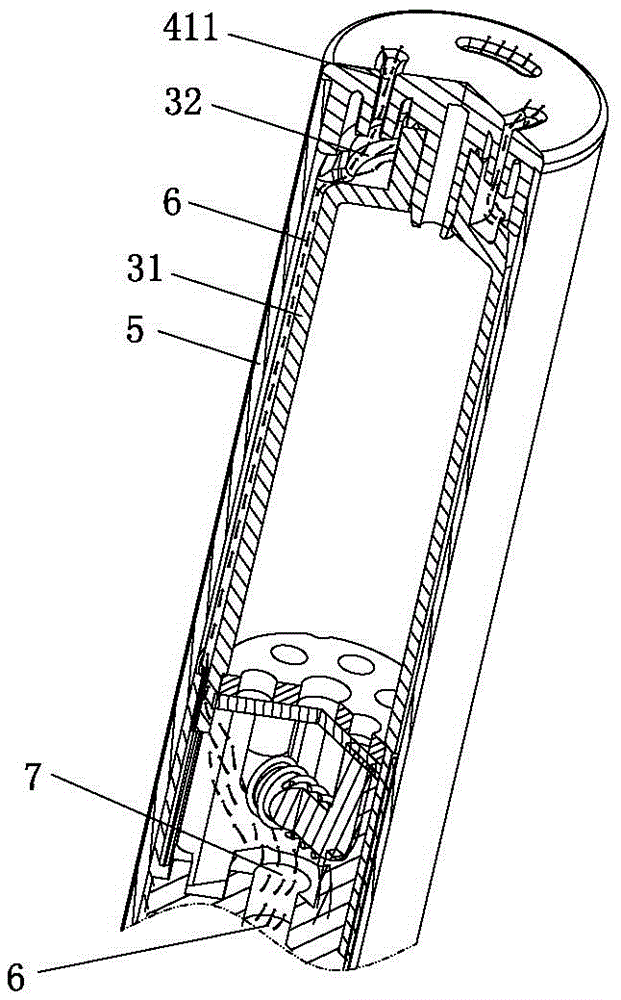

[0047] Figure 1 to Figure 6 A first embodiment of the invention is shown.

[0048] see Figure 1 to Figure 3 As shown, the electronic cigarette includes an outer tube 5 and a power supply assembly 1 built in the inner cavity of the outer tube 5 sequentially assembled together, an atomizer assembly 2 and a nozzle liquid cup assembly 3, and the liquid storage of the suction nozzle liquid cup assembly 3 The bottom end of the cup 31 is provided with a liquid injection through hole 32 arranged on the bottom end of the liquid storage cup 31 in a protruding or concave manner, and the liquid injection through hole 32 is sealed and connected by a plug 44; the liquid storage cup 31, the outer tube 5 and the An airflow passage 6 is formed between the nozzle plugs 4 . Both the power supply assembly 1 and the atomizer assembly 2 are known technologies, which are omitted he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com