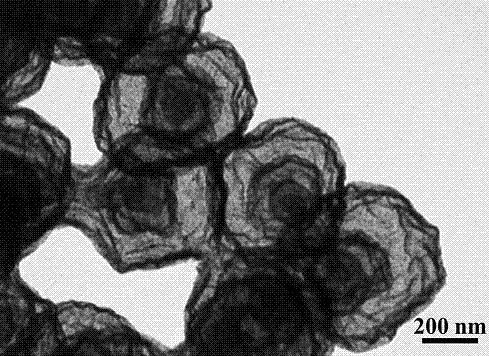

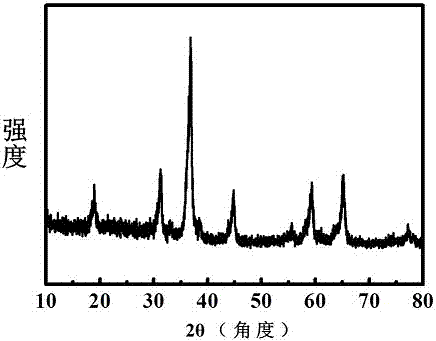

Preparation method for denitrified catalyst with nanometer multi-wall spherical spinel structure

A technology of spinel structure and denitrification catalyst, which is applied in the field of preparation of denitrification catalyst, can solve the problems of less surface pores, low specific surface area of nanoparticles, influence and other problems, and achieve the effects of improving catalytic activity, controlling production cost and reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Fructose was taken as the carbon precursor, and deionized water was configured to form a 0.2 mol / L sugar / water mixed solution, which was then transferred to a high-pressure reactor, and the o C under the condition of reaction for 5 h, after natural cooling, the product was alternately washed three times with water / ethanol, at 90 o Dry overnight at C and set aside;

[0027] Weigh cobalt acetate and manganese acetate with a molar ratio of 1:0.2 and dissolve them in ethanol / water mixture with a volume ratio of 1:1 to form a precursor with a concentration of (cobalt salt + manganese salt) of 0.2 mol / L solution; at the same time, weigh the prepared carbon template, mix it with the precursor solution at a mass ratio of 1:10, and sonicate for 30 minutes. Then at 20 o The adsorption was carried out under the condition of C, and the adsorption time was 4 h. After the adsorption was completed, the product was alternately washed with water / ethanol at 60 o C after drying at 1 ...

Embodiment 2

[0030] Glucose was taken as the carbon precursor, and deionized water was configured to form a 0.4 mol / L sugar / water mixed solution, which was then transferred to a high-pressure reactor, and the o C under the condition of reaction for 12 h, after natural cooling, the product was alternately washed three times with water / ethanol, at 90 o Dry overnight at C and set aside;

[0031]Weigh ferric chloride and manganese chloride with a molar ratio of 1:0.5, and dissolve them in ethanol / water mixture with a volume ratio of 1:3 to prepare (iron salt + manganese salt) with a concentration of 0.4 mol / L. Precursor solution; at the same time, weigh the prepared carbon template, mix it with the precursor solution at a mass ratio of 1:20, and sonicate for 30 minutes. Then at 50 o The adsorption was carried out under the condition of C, and the adsorption time was 6 h. After the adsorption was completed, the product was alternately washed with water / ethanol at 60 o C after drying at 3 o...

Embodiment 3

[0034] Take sucrose as the carbon precursor, and deionized water to form a 0.5 mol / L sugar / water mixed solution, which is then transferred to a high-pressure reactor, at 190 o C conditions were reacted for 20 h, after natural cooling, the product was washed three times with water / ethanol alternately, at 90 o Dry overnight at C and set aside;

[0035] Weigh cobalt nitrate and cerium nitrate with a molar ratio of 1:0.7, and dissolve them in an ethanol / water mixture with a volume ratio of 1:4 to prepare a precursor with a concentration of (cobalt salt + cerium salt) of 0.5 mol / L solution; at the same time, weigh the prepared carbon template, mix it with the precursor solution at a mass ratio of 1:30, and sonicate for 30 minutes. Then at 60 o The adsorption was carried out under the condition of C, and the adsorption time was 10 h. After the adsorption was completed, the product was alternately washed with water / ethanol at 60 o C after drying at 3 o The heating rate of C / min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com