Automatic receiving device for press machines

A press and automatic technology, applied in the field of presses, can solve problems such as the speed of presses not being too fast, personal injury of operators, economic losses of enterprises, etc., to achieve the effect of solving equipment failure, avoiding safety hazards, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

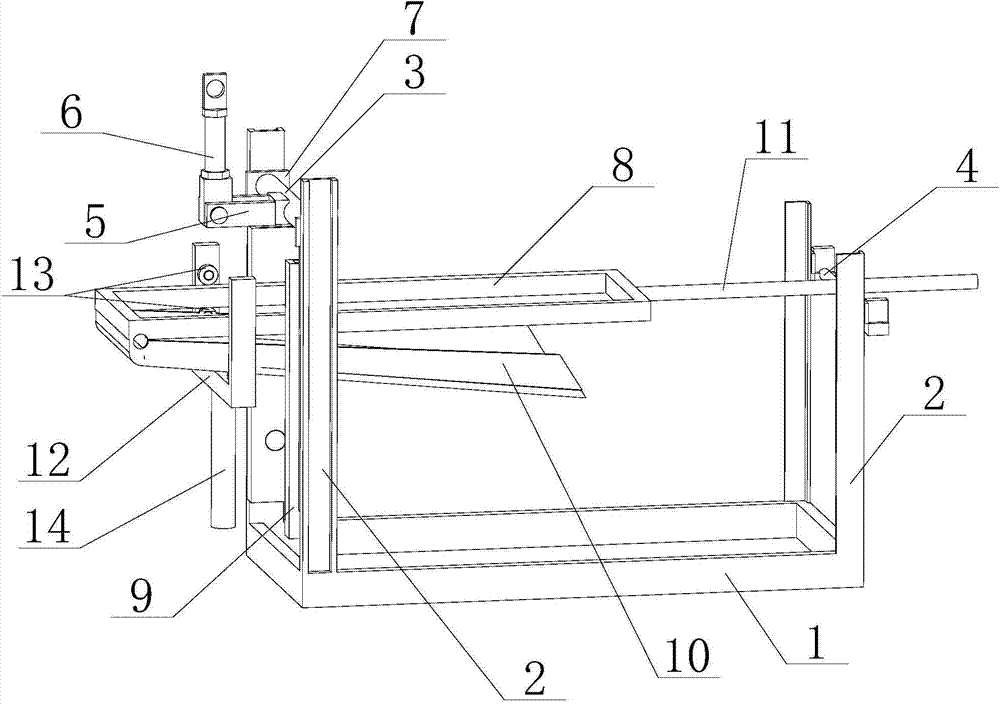

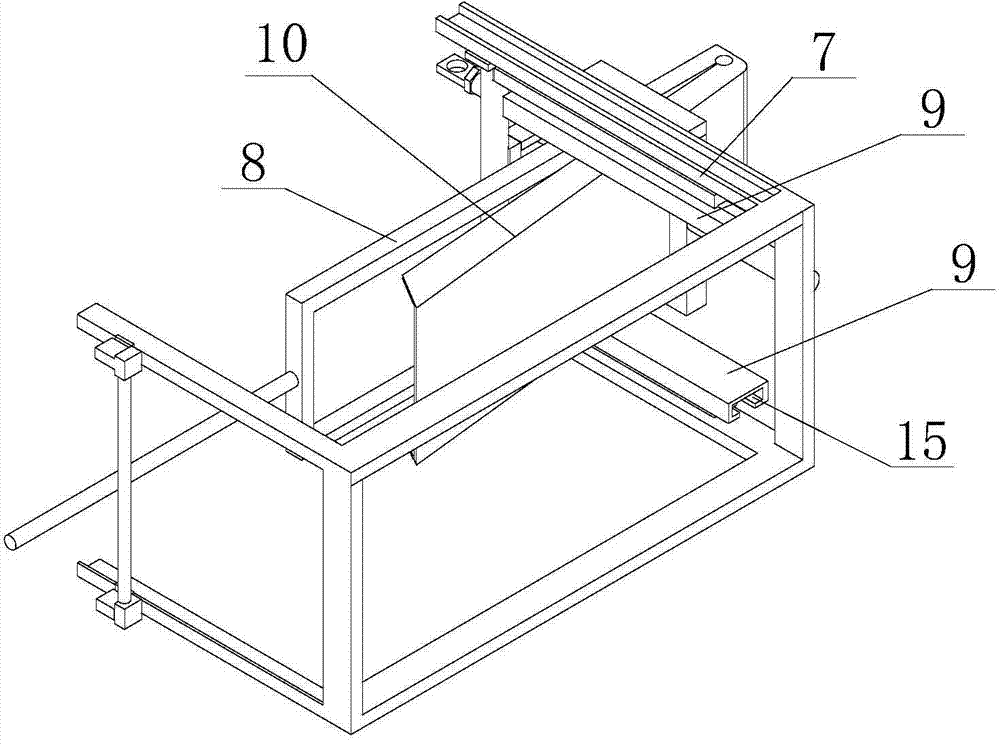

[0010] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an automatic material receiving device for a press proposed by the present invention; figure 2 It is a schematic diagram of the bottom structure of an automatic material receiving device for a press proposed by the present invention.

[0011] refer to figure 1 , figure 2 , a kind of automatic material receiving equipment for the press proposed by the present invention includes a base 1 fixed on the workbench of the press, a group of parallel stands 2 are arranged at the front and rear ends of the base 1, and the front end of the base 1 The stand 2 is connected with a transmission rod 3, and the two ends of the drive rod 3 are connected with the stand 2 through a fixed plate 7, and the rear end of the base 1 is connected with a rotating shaft 4 on the stand 2, and a connecting rod 5 is arranged on the transmission rod 3. , the connecting rod 5 is hinged with the first adjusting screw 6 conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap