Poor shell turning auxiliary tooling

An auxiliary tooling and differential shell technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing auxiliary tooling, which is complicated, time-consuming and labor-intensive, and increases production costs, and achieves simple structure, reduced equipment, and convenient clamping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

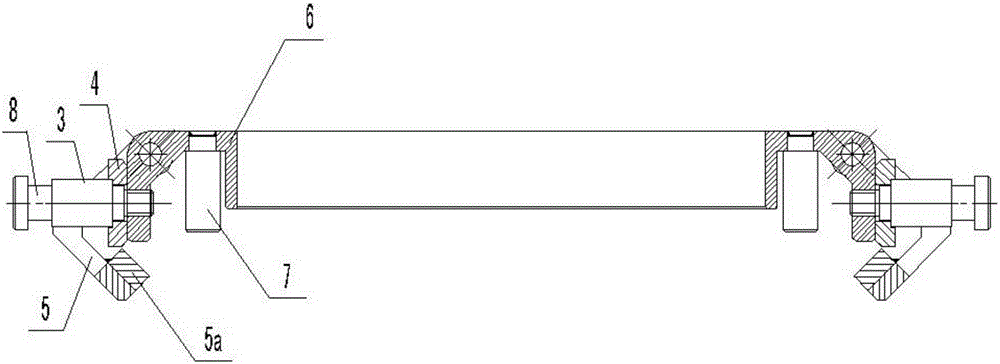

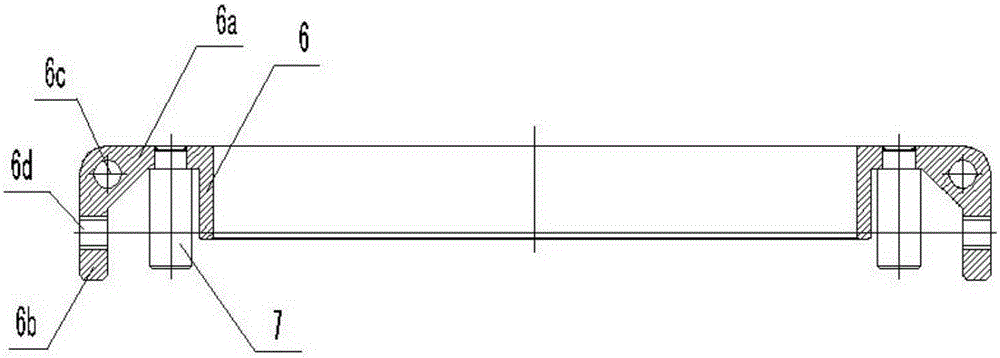

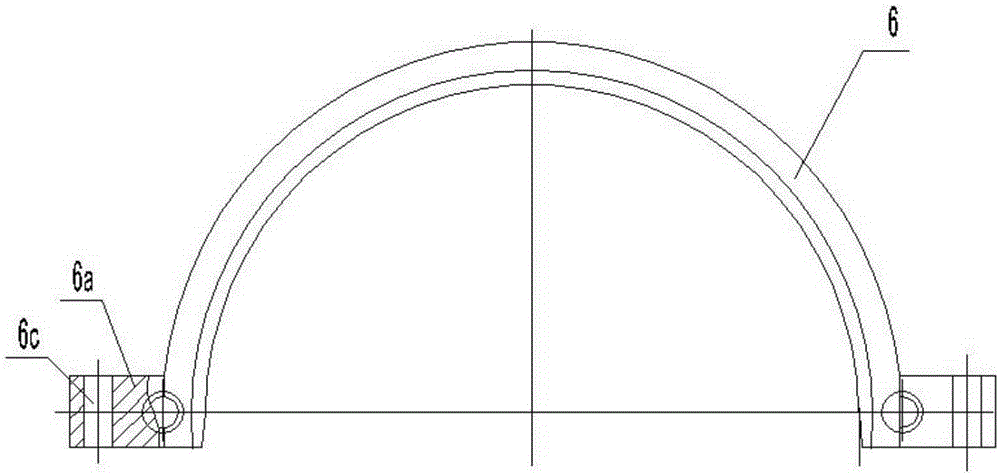

[0023] see figure 1 , Figure 2a with Figure 2b , the structural form of the auxiliary tool for turning over the differential shell in this embodiment is:

[0024] A half disc body 6 is provided, and a pair of vertical pin shafts 7 are arranged on the semi-disc body 6 at a radially symmetrical position, and the pair of vertical pin shafts 7 can be correspondingly inserted into a pair of bolt holes of the differential case 13; A pair of fixed clips that can fix the semi-disc body 6 on the differential case 13 are arranged on the radially symmetrical positions at both ends of the semi-disc body 6, and a pair of fixed clips are respectively provided with lifting ears 8, A pair of suspenders 11 in the hoist 10 can be fixedly sleeved on a pair of lifting lugs 8 of the fixed card, and the differential case 13 can be turned over in a vertical plane with the lifting lugs 8 as the rotating shaft.

[0025] Such as figure 1 , Figure 3a , Figure 3b with Figure 3c As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com