Water pump casing pin assembling device

An assembly device and pin technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low production efficiency, product scrap, production accidents, etc., to reduce labor intensity of workers, improve product qualification rate, and save production. cost effect

Active Publication Date: 2014-04-30

SHANDONG LIANCHENG PRECISION MFG CO LTD

View PDF8 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] 1. Due to the manual placement of pins during assembly, the pneumatic mechanism is likely to accidentally injure the hands of workers, resulting in production accidents

[0004] 2. The labor intensity of the workers who manually place the pins is high, and the pins cannot be placed vertically, and they will tilt when they are pressed down, causing the product to be scrapped

[0005] 3. Low production efficiency

Therefore, the existing assembly of the water pump housing can no longer meet the production needs.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

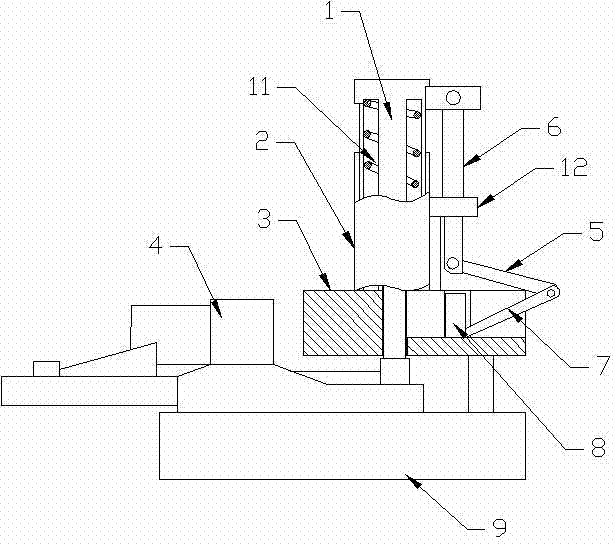

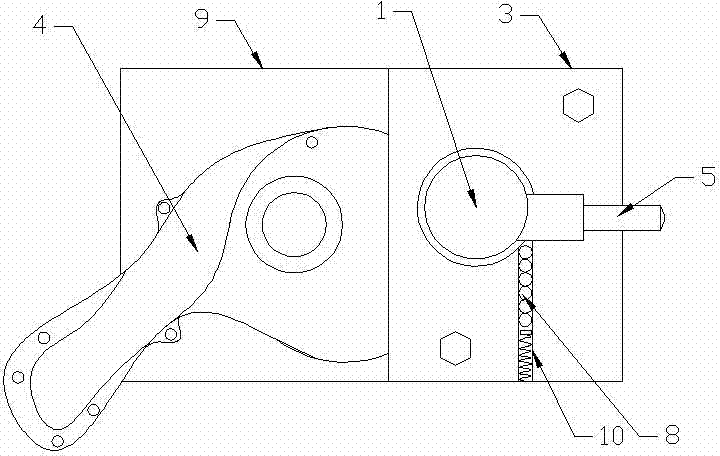

The invention relates to a hydraulic driving pin assembling device, in particular to a water pump casing pin assembling device which comprises an operating table. A pin mounting plate is fixed on the operating table, and a water pump casing is arranged between the pin mounting plate and the operating table. A pin conveying groove, a pin extrusion device and a pin conveying mechanism are fixed on the pin mounting plate, and the tail end of the pin conveying groove is provided with a pin push groove. The water pump casing pin assembling device is high in safety performance, improves production efficiency and can improve efficiency by over 20%; and the water pump casing pin assembling device further reduces labor intensity of workers and product production cost.

Description

technical field [0001] The invention relates to a hydraulically driven pin assembly device, in particular to a water pump housing pin assembly device. Background technique [0002] In the existing production, due to the large batch of water pump housing assembly parts, there are more than 400,000 sets a year, and flow operation is required to improve efficiency. However, the assembly of the water pump housing was previously done by manually placing the pins and then assembling with air pressure. The existing problems are: [0003] 1. Due to the manual placement of pins during assembly, the pneumatic mechanism is likely to accidentally injure the hands of workers, resulting in production accidents. [0004] 2. The labor intensity of the workers who manually place the pins is high, and the pins cannot be placed vertically, and they will tilt when they are pressed down, making the product scrapped. [0005] 3. Low production efficiency. Therefore the existing assembly about...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23P19/027

CPCB23P19/001B23P19/027

Inventor 石明昌蔡海泉

Owner SHANDONG LIANCHENG PRECISION MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com