Vice machine of multi-station rotary ball valve assembly machine

A rotary, multi-station technology, applied in the direction of assembly machines, metal processing, manufacturing tools, etc., can solve problems such as misinstallation of ball valve accessories, unqualified products, and failure to obtain guarantees, so as to reduce the defective rate and reduce the cost of operators. The effect of less and less leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

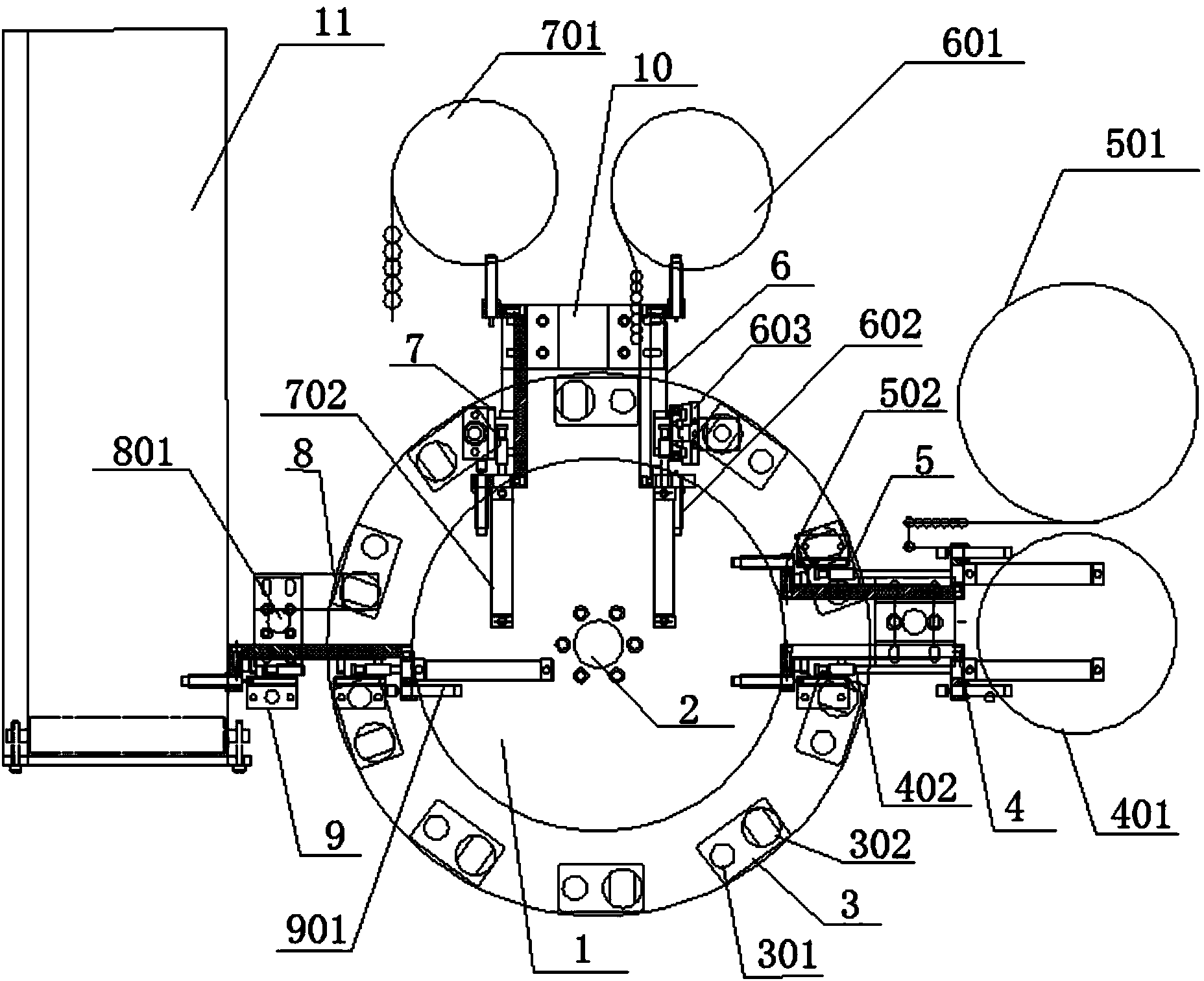

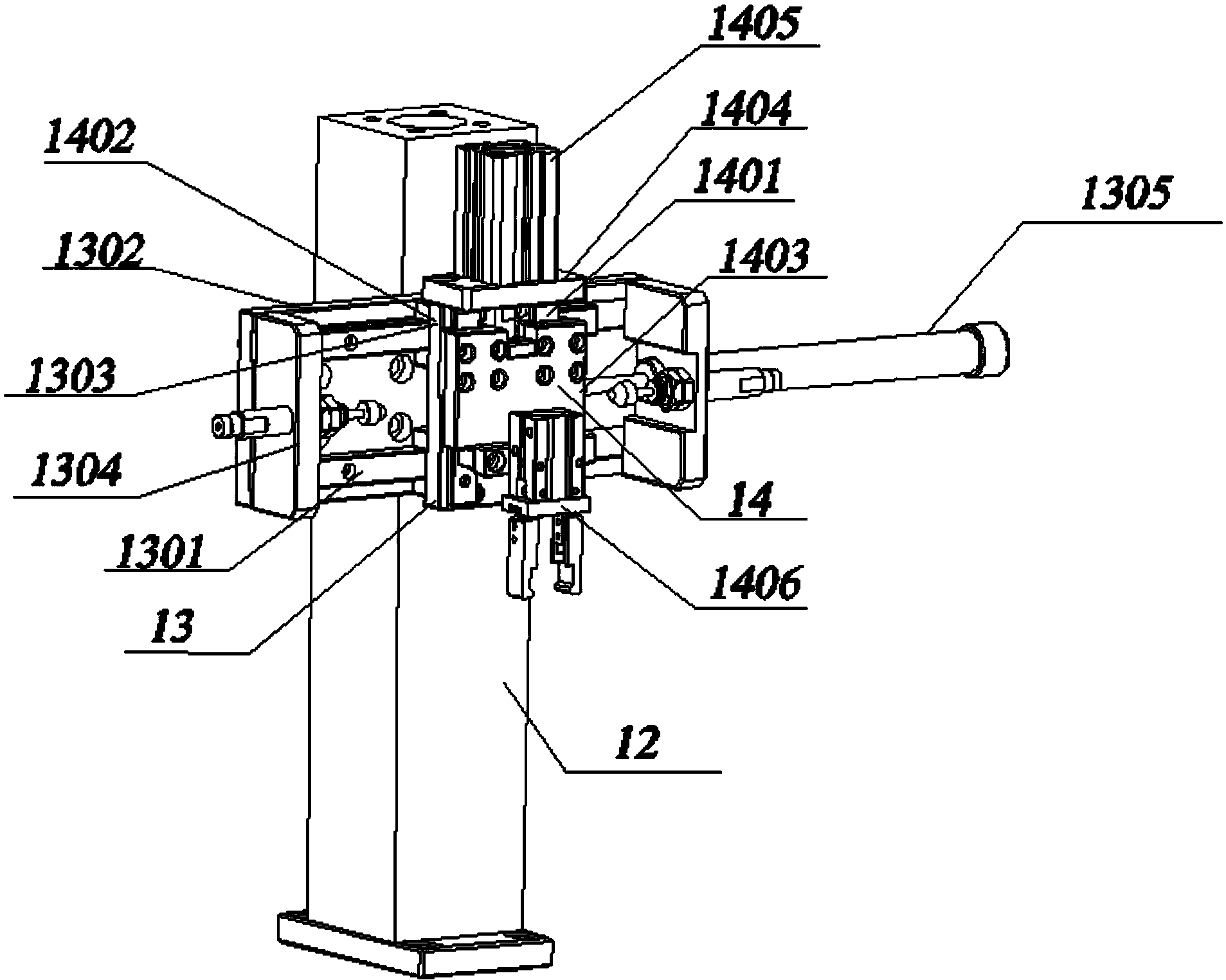

[0023] Such as figure 1 As shown, the auxiliary machine of the multi-station rotary ball valve assembly machine includes a circular worktable 1, a transmission device 2 and a driving device. Ten sets of positioning fixtures 3 are arranged on the circular worktable 1 along the circumference, and the corresponding positioning fixtures are around the outside 3 position in order to set the valve body hole metal gasket assembly device 4, the valve body hole Teflon packing assembly device 5, the valve body hole pressure cap assembly device 6, the valve cover Teflon sealing seat assembly device 7, the valve cover Teflon sealing seat press-fitting and valve body unloading device 8, valve cover unloading device 9.

[0024] The circular workbench 1 and the transmission device 2 are concentrically installed on the base, wherein the transmission device is a 10 equal parts cam intermittent divider, and the driving device is a worm gear reducer motor assembly installed on the base, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com