Automatic machining tool of box machining center

A machining center and automatic processing technology, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of low production efficiency, waste of motor casing, troublesome fixing of the casing with fixtures, etc. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

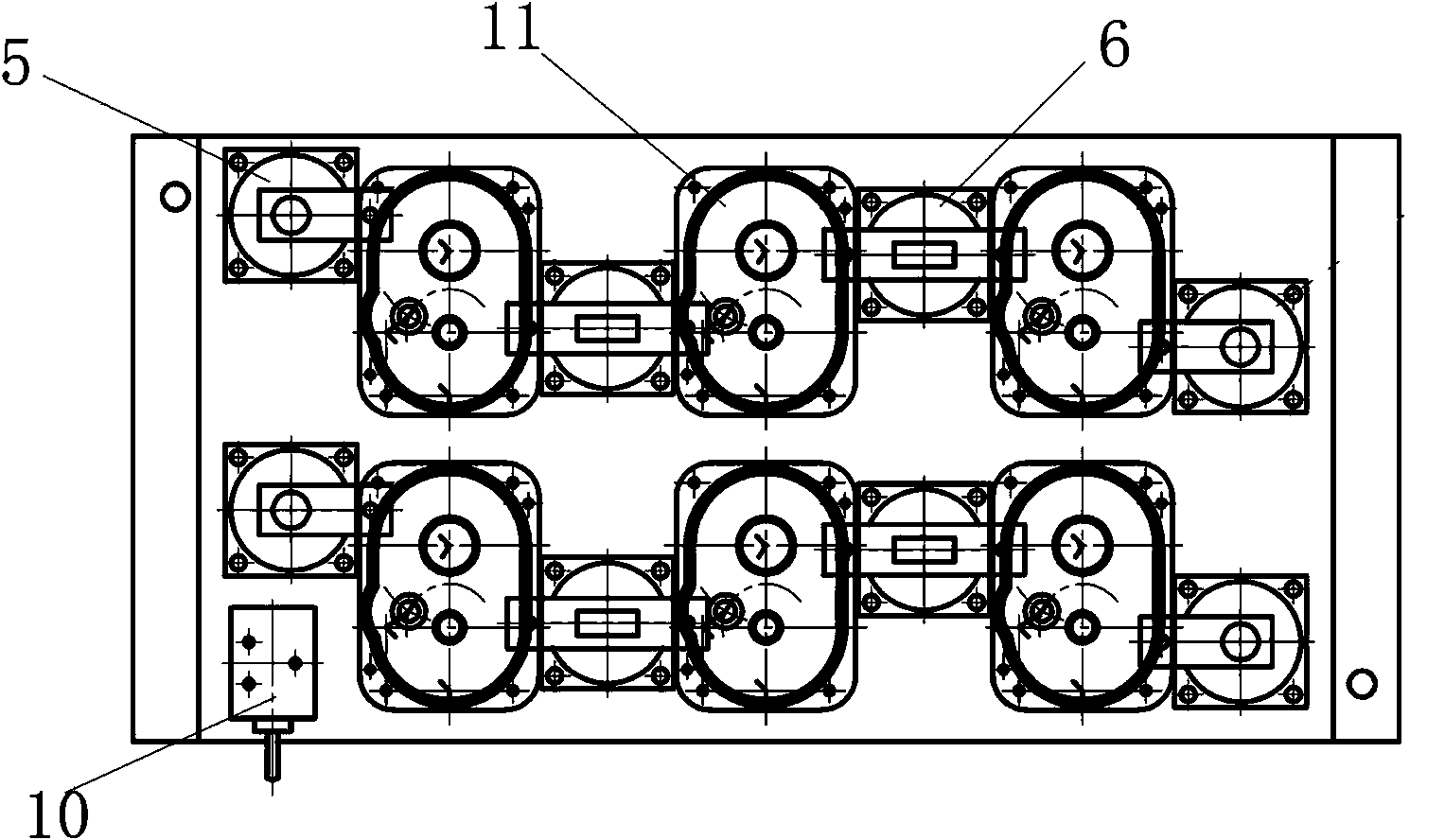

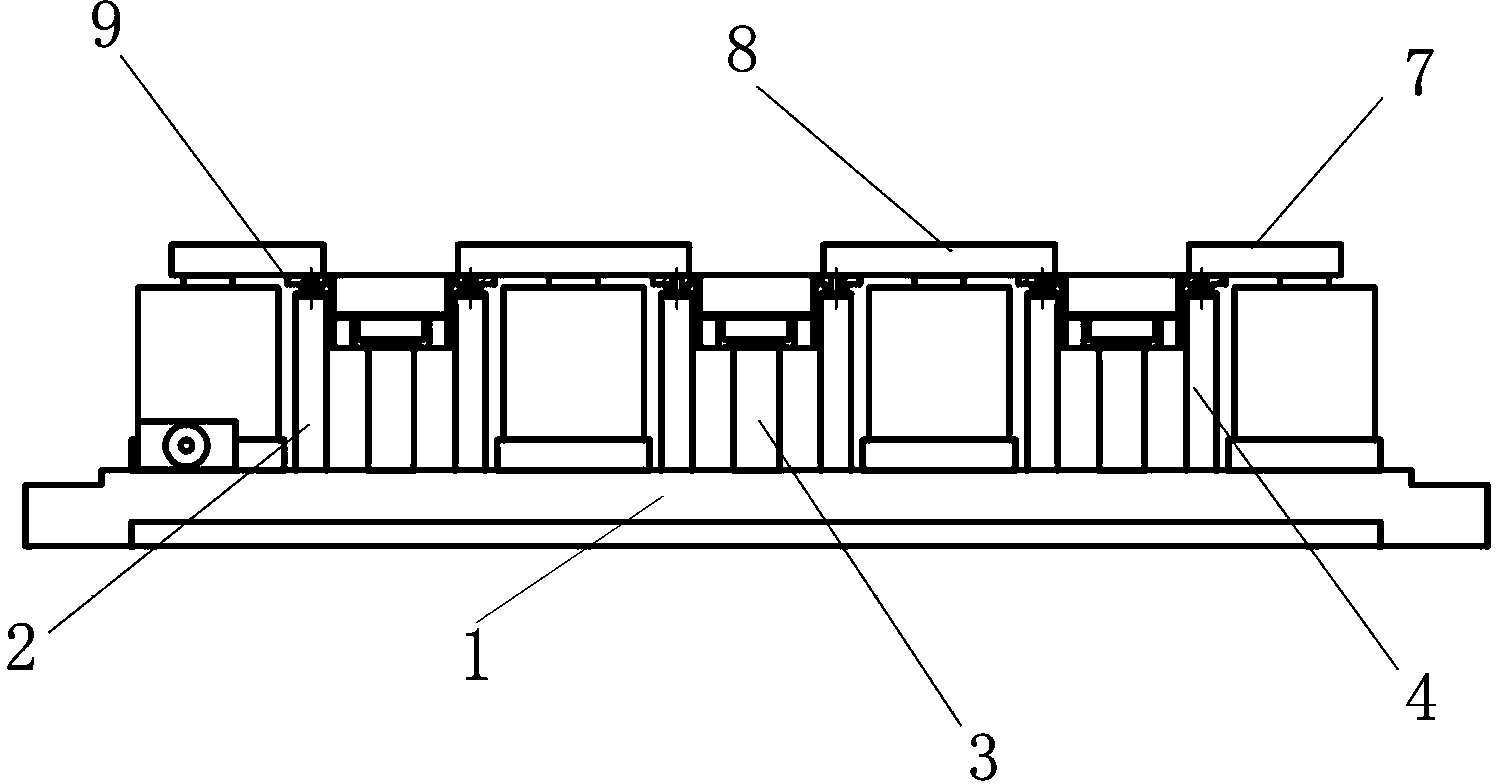

[0010] Such as figure 1 and 2 As shown, the automatic processing tooling of the box machining center of the present invention includes a base plate 1, on which a plurality of left positioning columns 2, bearing chamber positioning columns 3 and right positioning columns 4, left positioning columns 2 and right positioning columns 4 are arranged. A unilateral automatic rotation cylinder 5 is respectively provided on the outside of the outer side, a bilateral automatic rotation cylinder 6 is arranged between the left positioning column 2 and the bearing room positioning column 3, and the bearing room positioning column 3 and the right positioning column 4, and the unilateral automatic rotation cylinder 5 A unilateral briquetting block 7 is set on the top, a bilateral briquetting block 8 is set on the top of the bilateral automatic rotating cylinder 6, a soft gasket 9 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com