Automatic conveyer

A transmission device and automatic technology, which is applied in the field of automation equipment manufacturing, can solve the problems of restricted share, low work efficiency and high cost, and achieve the effects of cost reduction, simple and practical structural design, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

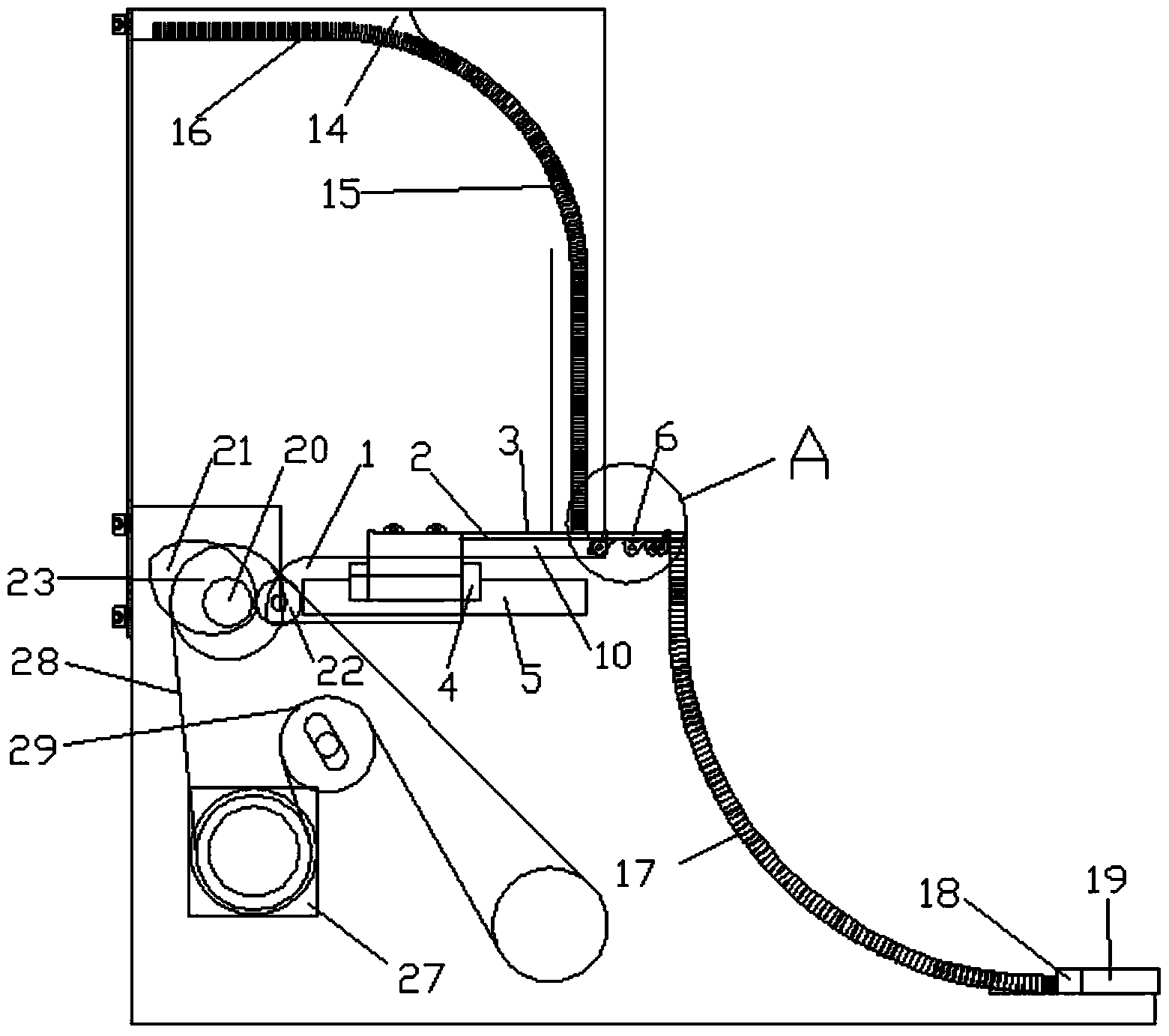

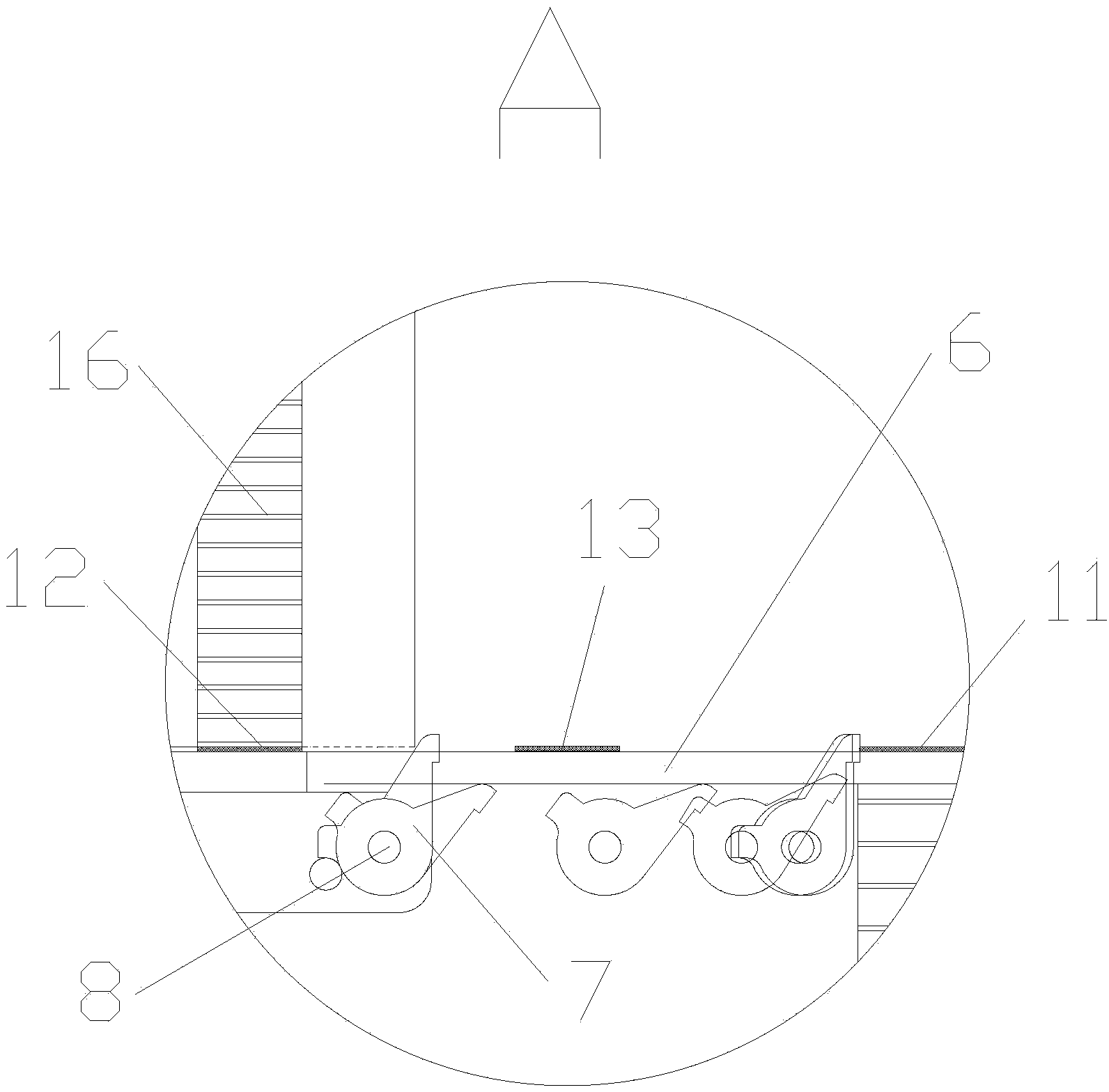

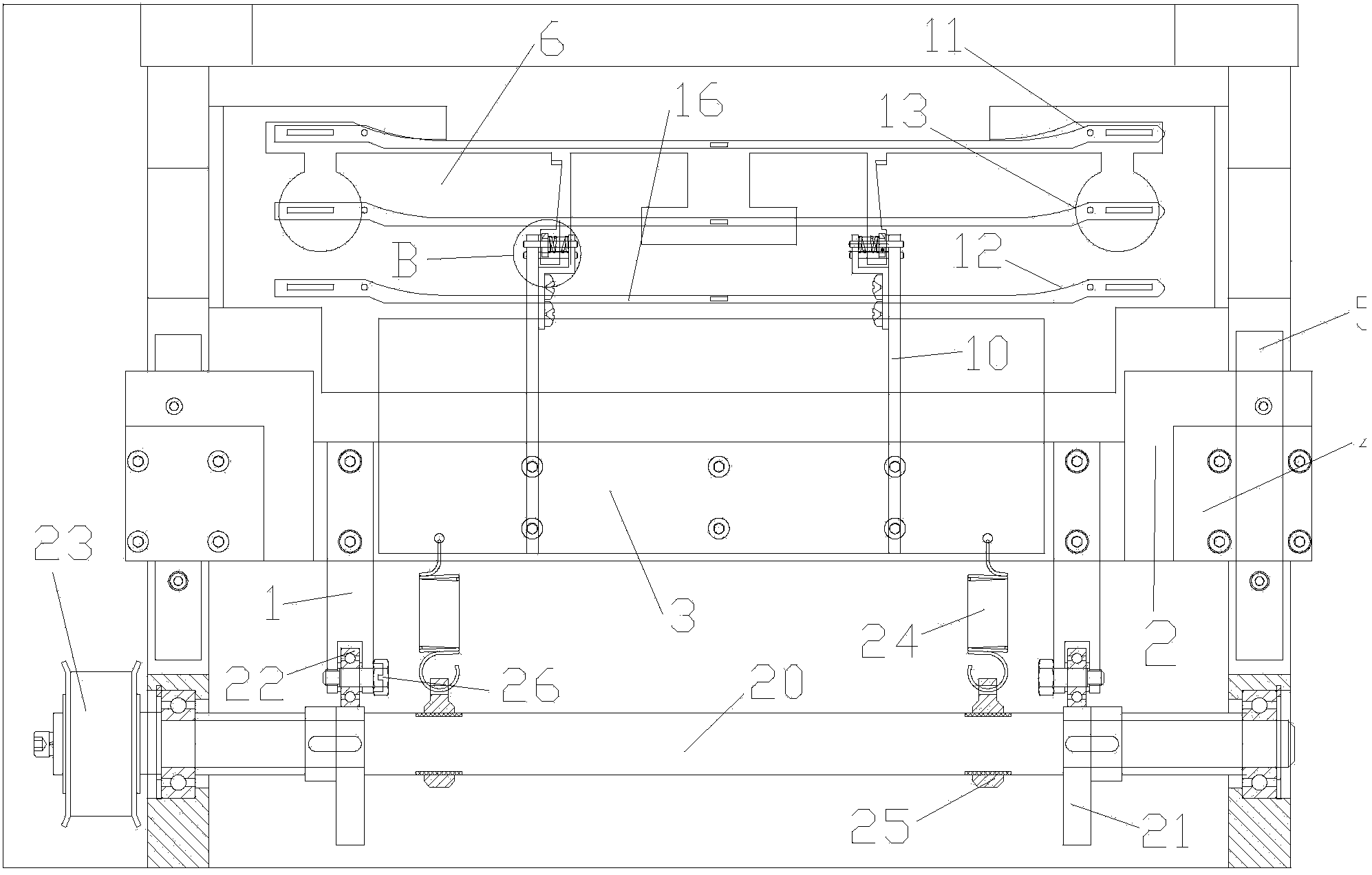

[0019] The present invention is described below in conjunction with accompanying drawing.

[0020] attached figure 1 -6 is an automatic conveying device according to the present invention, including a feeding mechanism, a feeding mechanism, a discharging mechanism and a feeding camshaft mechanism for providing power; the feeding mechanism includes two feeding support roller frames 1, The feeding plate 2, the pushing plate 3, the slide rail 4 fixed on the slide rail seat 5, the feeding shift fork mechanism and the heat twisting work plate 6; wherein the feeding support roller frame 1 is fixed on the bottom surface of the feeding plate 2, and the pushing plate 3 is set at the middle position of the top surface of the feeding plate 2, and the feeding plate 2 is connected with the slide rail 4; the feeding fork mechanism includes a feeding fork 7, a pin shaft 8, a spring A9 and a fork frame 10, wherein the spring A9 is sleeved on the pin shaft 8, and is fixed on the fork frame 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com