Jetting head for non-contact type large-character ink-jet printer

A non-contact, large-character technology, applied in the field of inkjet printers, can solve problems such as difficult installation, easy ink leakage, and inconvenient maintenance, and achieve the effects of safe and reliable performance, simple manufacturing and installation, and high working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

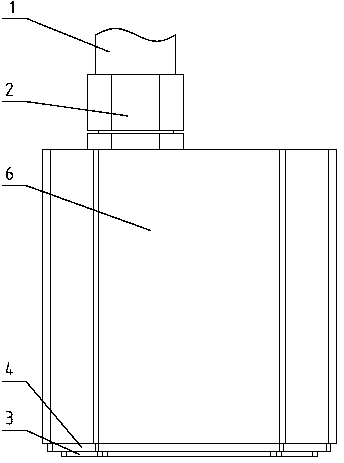

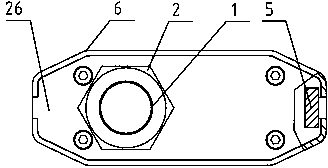

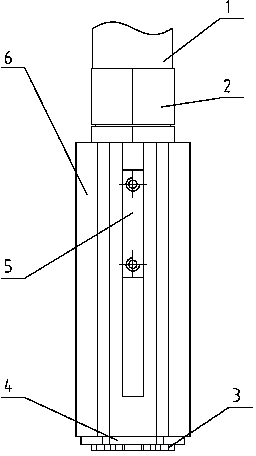

[0034] Such as Figure 1-Figure 11 As shown, the present invention is used for the nozzle of the non-contact large-character inkjet printer, the installation base 4, the spray chamber, the nozzle plate 3, the static core module, the valve pipe module, the moving core assembly, the driving coil 19 and the nozzle cable, The nozzle plate 3 is sealed on the spray chamber, and a row of nozzle holes 31 is processed on the nozzle plate 3. The nozzle ink supply pipe and the return pipe are connected to the spray chamber. The valve pipe module is fixed on the installation base 4, and the static core module passes through The valve pipe module is connected with the installation base 4, and the static core module, the valve pipe module, the moving core assembly and the driving coil together form a nozzle with the same number of nozzle holes on the nozzle plate, and are used to independently control each nozzle on the nozzle plate. Orifice A solenoid valve that ejects ink to form ink drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com