A marine diesel fuel injector

A marine diesel engine and fuel injector technology, which is applied to machines/engines, mechanical equipment, engine components, etc., can solve the problems of low modularization of fuel injectors, high manufacturing difficulty, poor interchangeability, etc., and can adapt to changes in fuel quality. The effect of strong ability, low manufacturing difficulty and low processing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

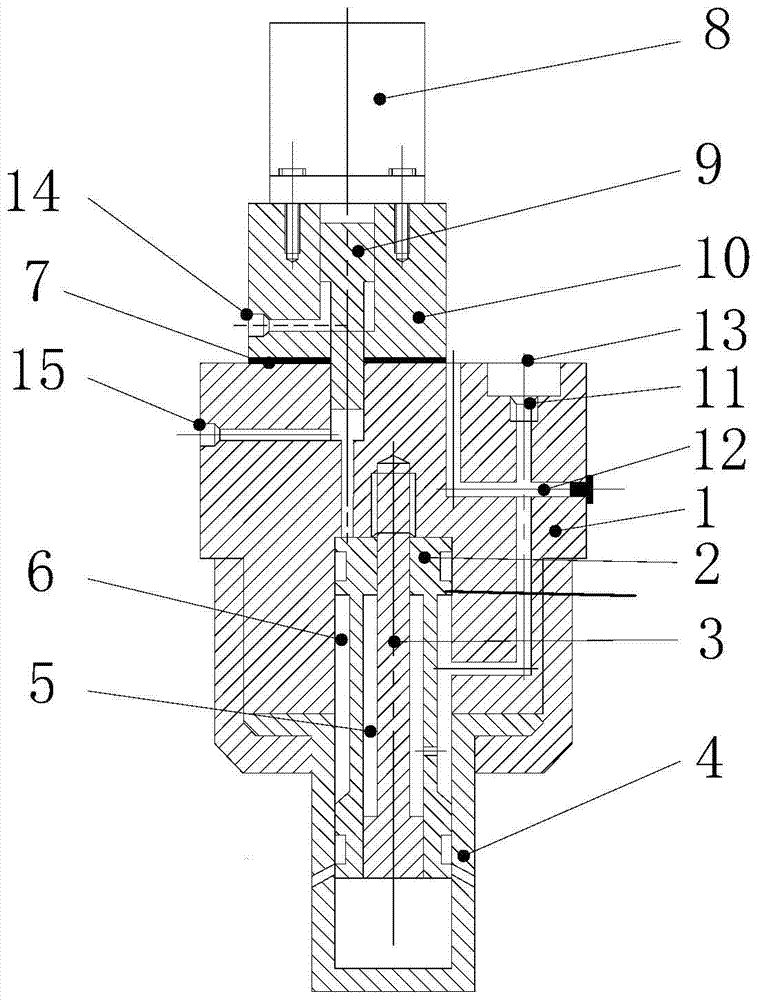

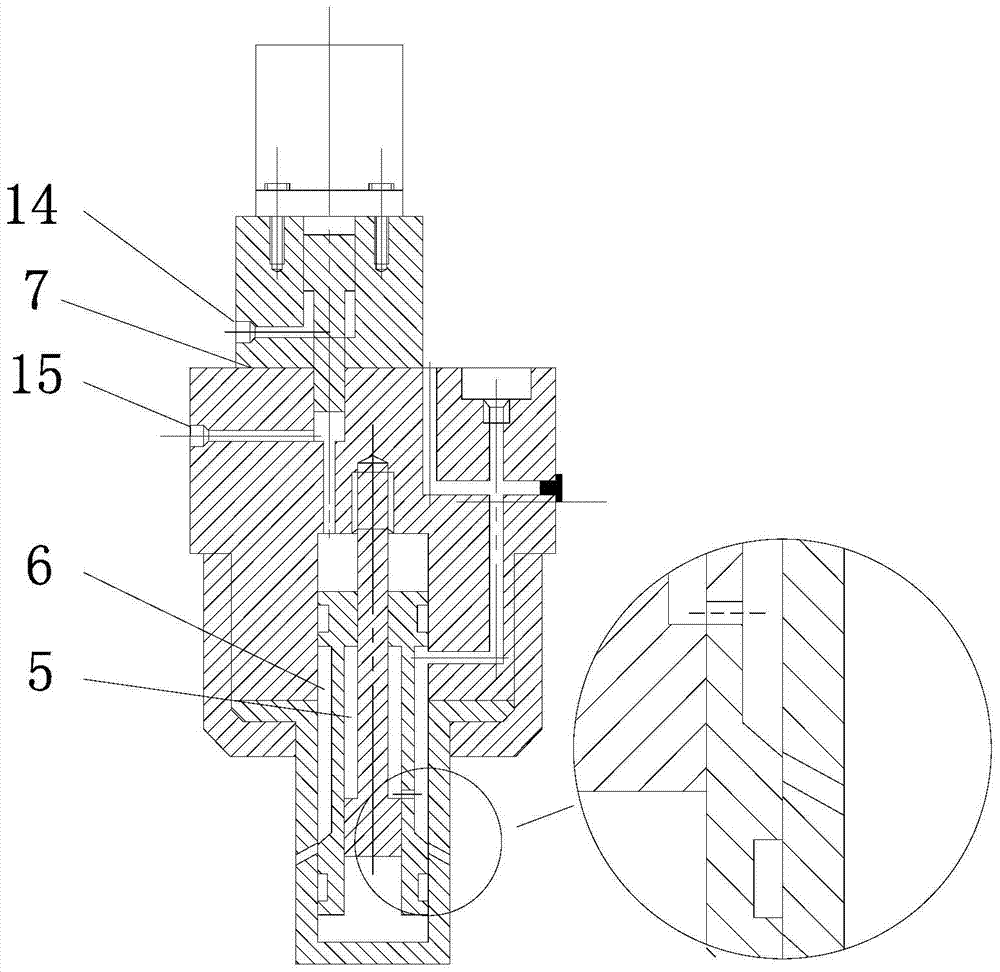

[0018] Such as figure 1 and figure 2 As shown, the marine diesel fuel injector of the present invention includes a body 1, a piston assembly and a solenoid valve control module. The upper part of the body 1 is provided with a high-pressure oil pipe interface 13 and a mounting seat 11, and the high-pressure oil pipe interface 11 is connected to an external high-pressure oil pipe to receive high-pressure fuel from a high-pressure oil pump or a high-pressure fuel common rail system. The mounting seat 11 is connected to the high-pressure oil pipe interface 13 and has an oil hole, that is, the inner hole of the mounting seat. The oil hole is tapered, and is in contact with the conical surface of the high-pressure oil pipe interface and is in sealing connection. The oil hole communicates with the first oil passage. At the same time, the body 1 is provided with a fuel leakage hole 12, the fuel leakage hole communicates with the second oil passage connected to the outside world, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com