An Experimental Setup for Quickly Evaluating the Performance of Exhaust Gas Turbocharger Centrifugal Compressor

A centrifugal compressor and exhaust gas turbine technology, applied in the direction of machine/engine, mechanical equipment, pump control, etc., can solve the problems affecting the progress of the compressor experiment and design, long processing cycle of the compressor, etc., to shorten the processing cycle and achieve a simple structure. , the effect of rapid processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific embodiment of the present invention is further described below:

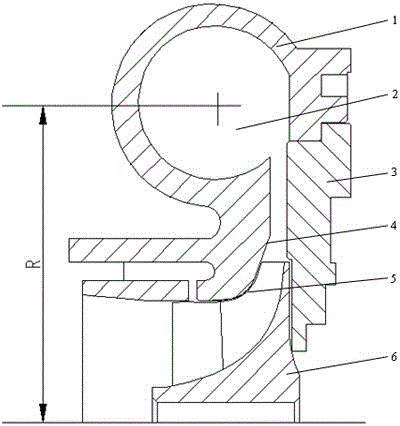

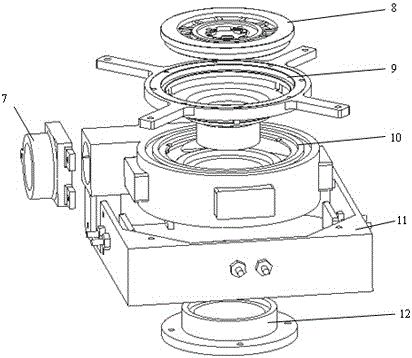

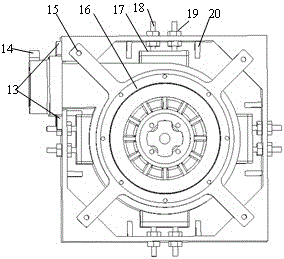

[0058] An experimental device for quickly evaluating the performance of a centrifugal compressor for an exhaust gas turbocharger, consisting of an outlet pipe, a back plate (the original part of the turbocharger), a wheel cover flow surface, a volute flow channel, a basic casing and an inlet flange The conventional compressor volute consists of two parts, of which the wheel cover flow surface and the volute flow channel are two key components;

[0059] The back plate, the wheel cover flow surface parts, the volute flow channel, the basic shell, and the inlet flange are overlapped and fixedly connected from top to bottom; the processing method of the wheel cover flow surface parts is turning and milling, and the material can be stronger. Steel materials; the processing method of the volute flow channel is resin rapid prototyping technology, and the wall thickness is 3 to 5 times the wall thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com