Down-hole deep dynamic compactor

A dynamic tamping machine and deep-layer technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of low efficiency, low tamping machine efficiency, inconvenient pile alignment, etc., and achieve simple and reliable operation, improved work efficiency, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

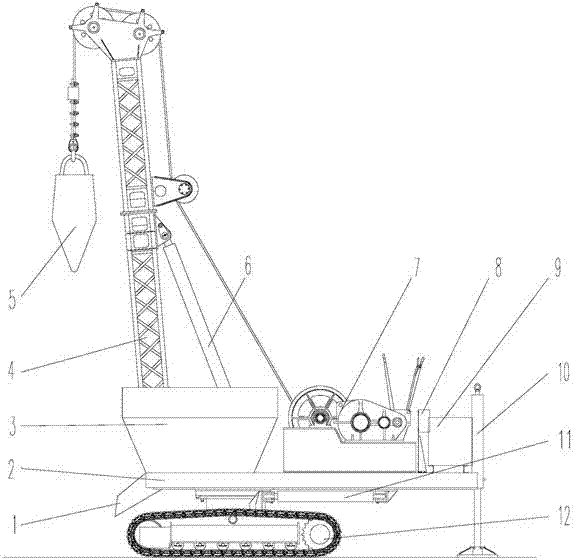

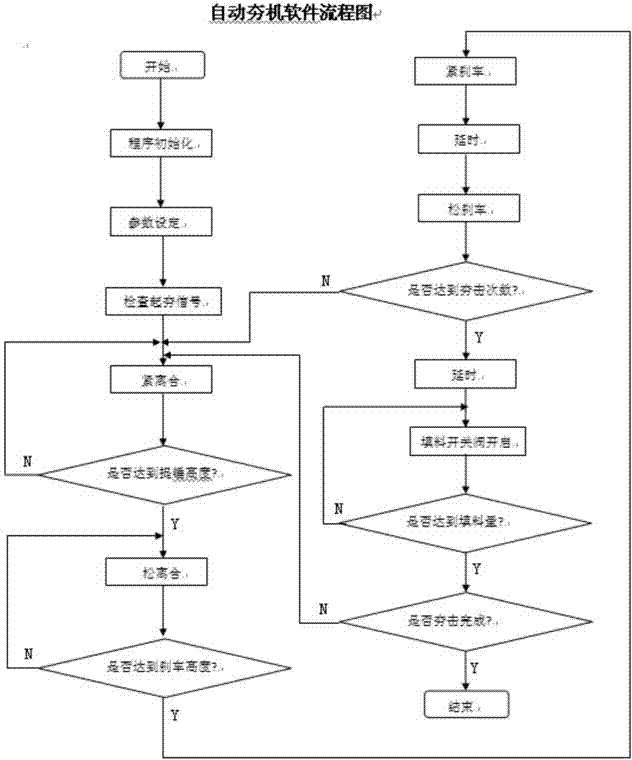

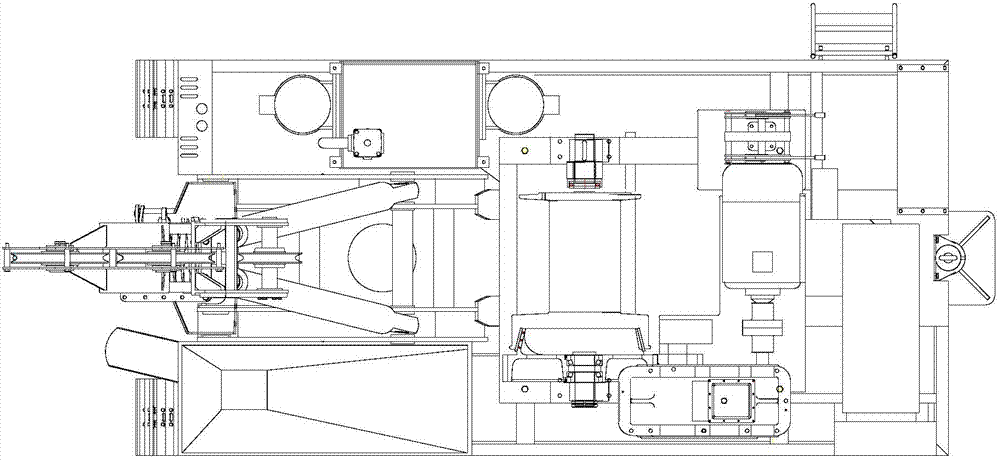

[0022] see figure 1 , figure 2 and image 3 , the chassis 12 is a walking chassis, and the walking chassis is a crawler walking device. The platform 2 is rotatably installed on the chassis 12, and the rotary oil cylinder 11 between the platform and the chassis 12 is arranged on the platform 2. Main pump motor, fuel tank, operating Platform 8, hopper 3 and material tongue 1, hydraulic system and control system 9, the lower end of mast 4 is hinged on platform 2, and two mast oil cylinders 6 are hinged between platform 2 and mast 4, and the wire rope on winch 7 is wound The goose head pulley on the transition pulley and the mast 4 is fixedly connected to the tamper 5, and a leg cylinder 10 is connected to the platform 2; the winch 7 has a retractable oil cylinder or cylinder, and the pipeline and control on the cylinder or cylinder Valve connection; the outlet of the hoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com