Steel column drum rack support type hydraulic lifting overall steel platform cross truss layer construction method

A construction method and integral steel technology, applied in the direction of building structure support, building structure support, formwork/formwork/working frame, etc., can solve the problems of inability to erect truss layers, avoid splitting and combining operations, reduce construction costs, Guaranteed safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

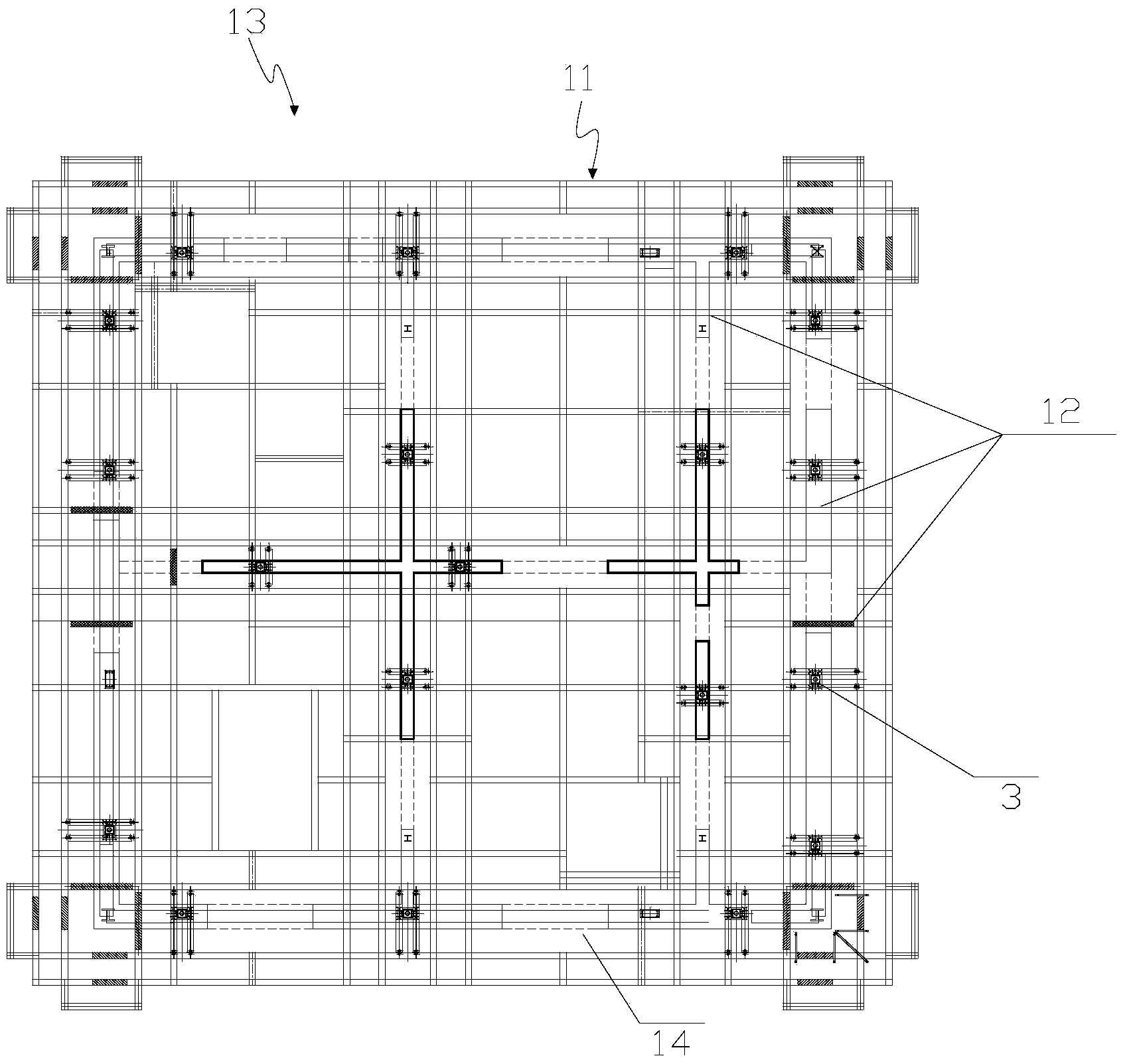

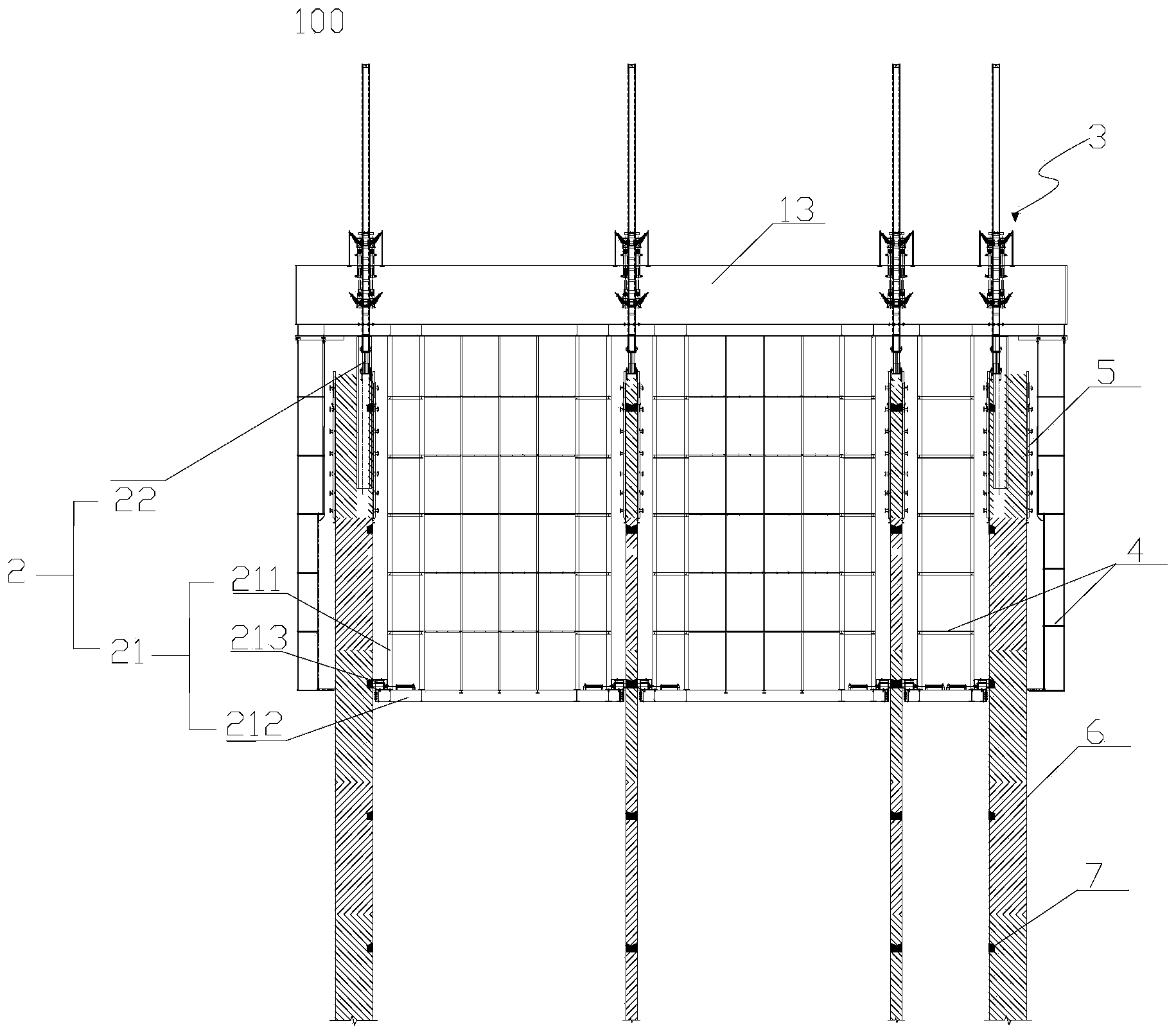

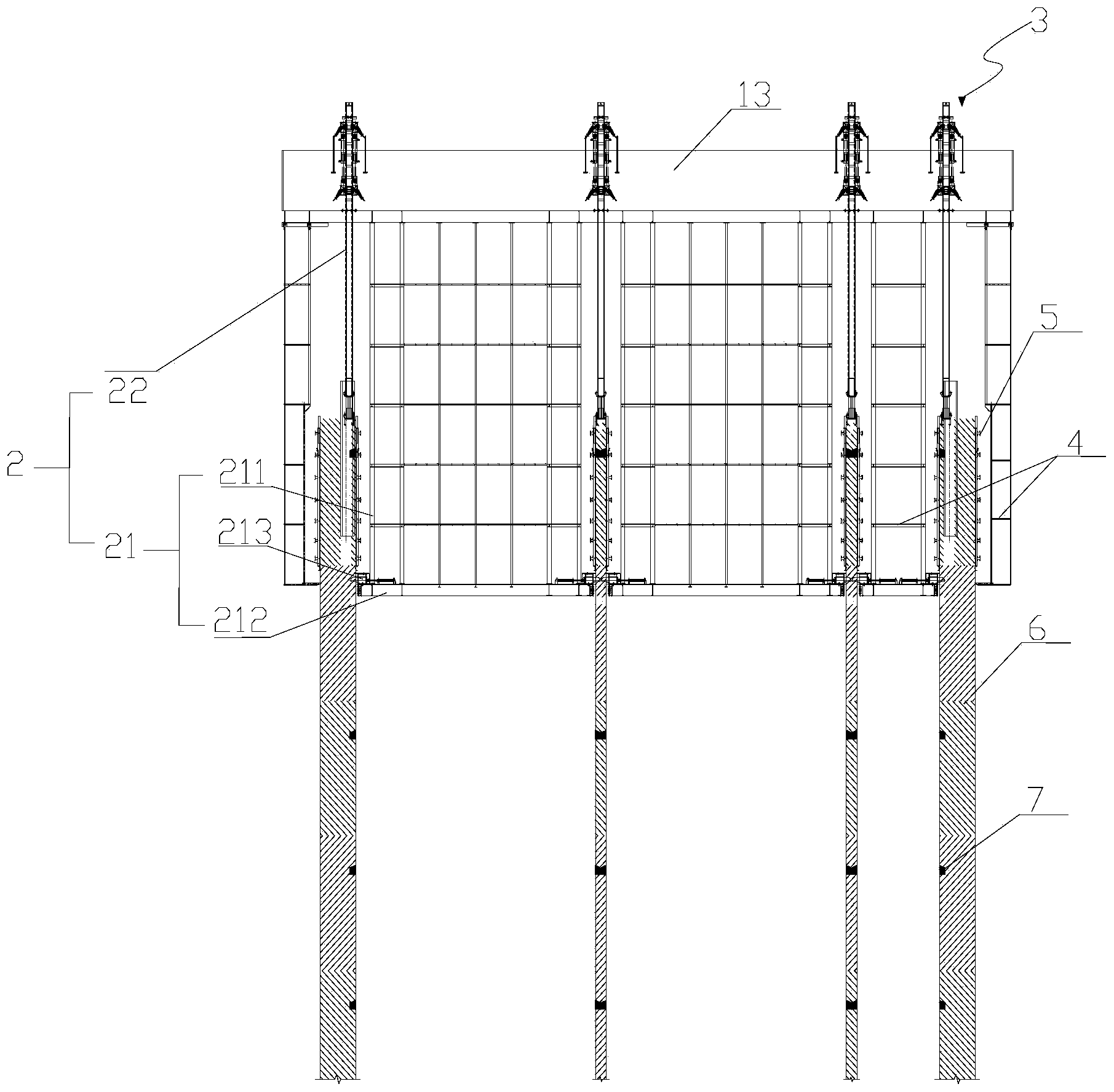

[0030] The core idea of the present invention is that when the steel column frame alternately supported hydraulic climbing integral steel platform is being constructed on the truss layer, the connecting beams on the steel platform system are removed step by step, so that the integral steel platform has a cavity, and the composition is formed through the cavity. The components of the truss layer are hoisted into the core tube respectively, and the components of the truss layer are connected and assembled in the fully enclosed operating space formed by the steel platform formwork system to form the truss layer. The above-mentioned construction method relies on the steel platform formwork system to be installed and lifted layer by layer along the vertical section of the truss layer, avoiding the disassembly and assembly of the steel platform formwork system at high altitude, and the entire construction process is carried out in a fully enclosed space, maximizing The construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com