Noise qualification approval equivalent test flight method of large transport-category aircraft

A transport aircraft and certification technology, applied in the field of effective flight test, can solve the problems of wasting manpower, material resources, affecting flying characters, and wasting flight sorties, etc., and achieves the effect of flexible selection, reduction of engine life, and construction cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

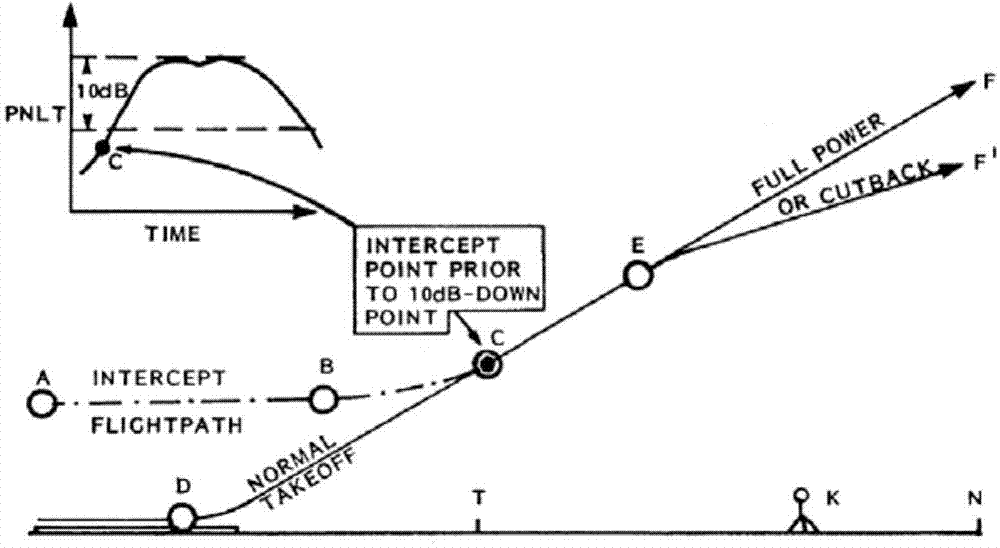

[0032] Example 1: Fly-by noise measurement

[0033] a) Arrange three noise measurement points near the airport, two lateral measurement points S1 and S2, and one overflight measurement point C;

[0034] b) Predetermine the reference flight path of the aircraft passing over the noise measurement point, see image 3 .

[0035] c) After the aircraft takes off from the field and reaches the sky above the noise measurement point, go around according to the pre-determined flight path and engine power, and measure the noise of the lateral and overflight noise measurement points;

[0036] d) According to the requirements of CCAR36, judge the validity of test results in real time;

[0037] e) Data processing

[0038] First calculate the flyover noise EPNL of each actual flight altitude, and then correct the flyover noise EPNL to the reference track flight altitude of 1200ft, see Table 1. Then correct the EPNL at the flight altitude of 1200ft to the reference condition (D=6500m, H=2...

Embodiment 2

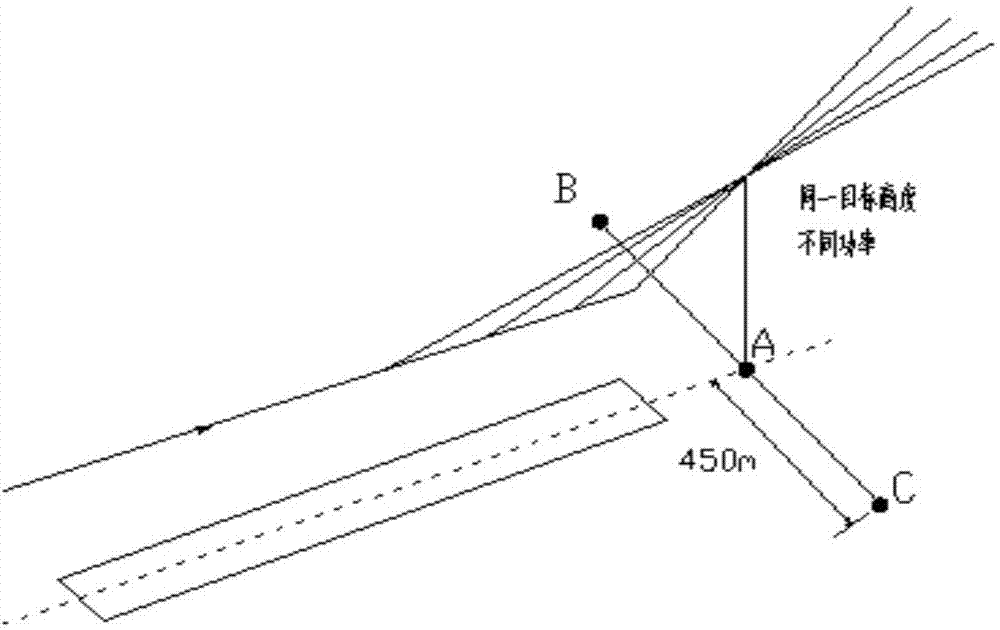

[0046] Example 2: Lateral Noise Measurement

[0047] a) Arrange three noise measurement points near the airport, two lateral measurement points S1 and S2, and one overflight measurement point C;

[0048] b) Predetermine the lateral noise reference flight path of the aircraft passing over the noise measurement point, see Figure 4 .

[0049] c) After the aircraft takes off from the field and reaches the sky above the noise measurement point, go around according to the pre-determined flight path and engine power, and measure the noise at the lateral noise measurement point;

[0050] d) According to the requirements of CCAR36, judge the validity of test results in real time;

[0051] e) Data processing

[0052] First, calculate the EPNL of the measured power at the two lateral noise measurement points according to the lateral noise test. The results are shown in Table 4 and Table 5. The relationship curve between the aircraft height and EPNL is determined by quadratic fitting,...

Embodiment 3

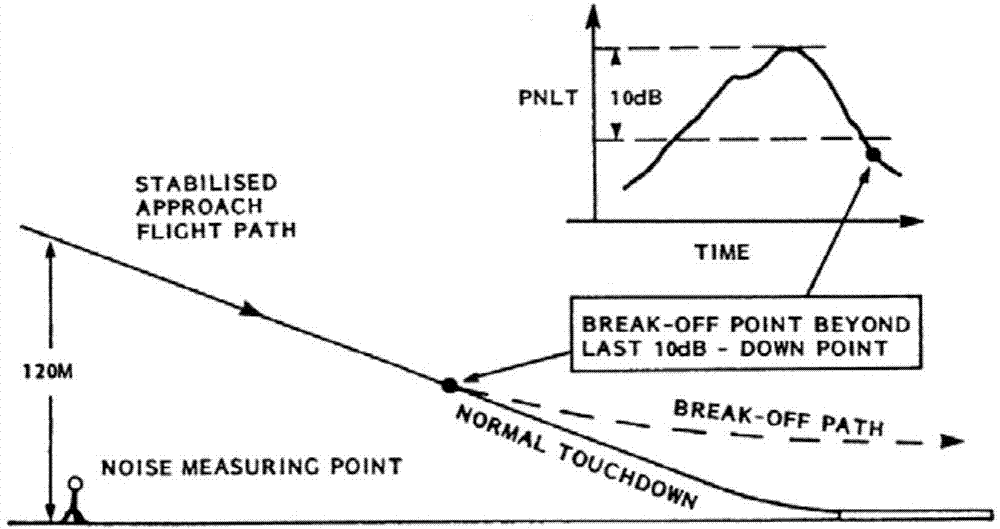

[0067] Example 3: Approach noise measurement

[0068] a) Arrange a noise measurement point near the airport, the approach noise measurement point;

[0069] b) Predetermine the approach reference for the aircraft passing over the noise measurement point, see Figure 5 ;

[0070] c) After the aircraft takes off from the field and reaches the sky over the noise measurement point, it conducts a go-around according to the pre-determined flight track and engine power, and the noise of the approach noise measurement point;

[0071] d) According to the requirements of CCAR36, judge the validity of test results in real time;

[0072] e) Data processing.

[0073] First, calculate the approach noise EPNL at each actual flight altitude, then correct the approach noise EPNL to the reference track flight altitude of 394ft, and then perform the quadratic fitting of the engine power and EPNL to obtain the approach noise level and confidence interval of 90 % confidence level, the approach ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com