Method and device for precisely testing rolling resistance of tyres

A technology of rolling resistance and testing method, which is applied in the direction of automobile tire testing, etc., can solve the problems of installation error, difficult quantitative description, and harsh environment of component force sensor, and achieve the effect of eliminating error and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

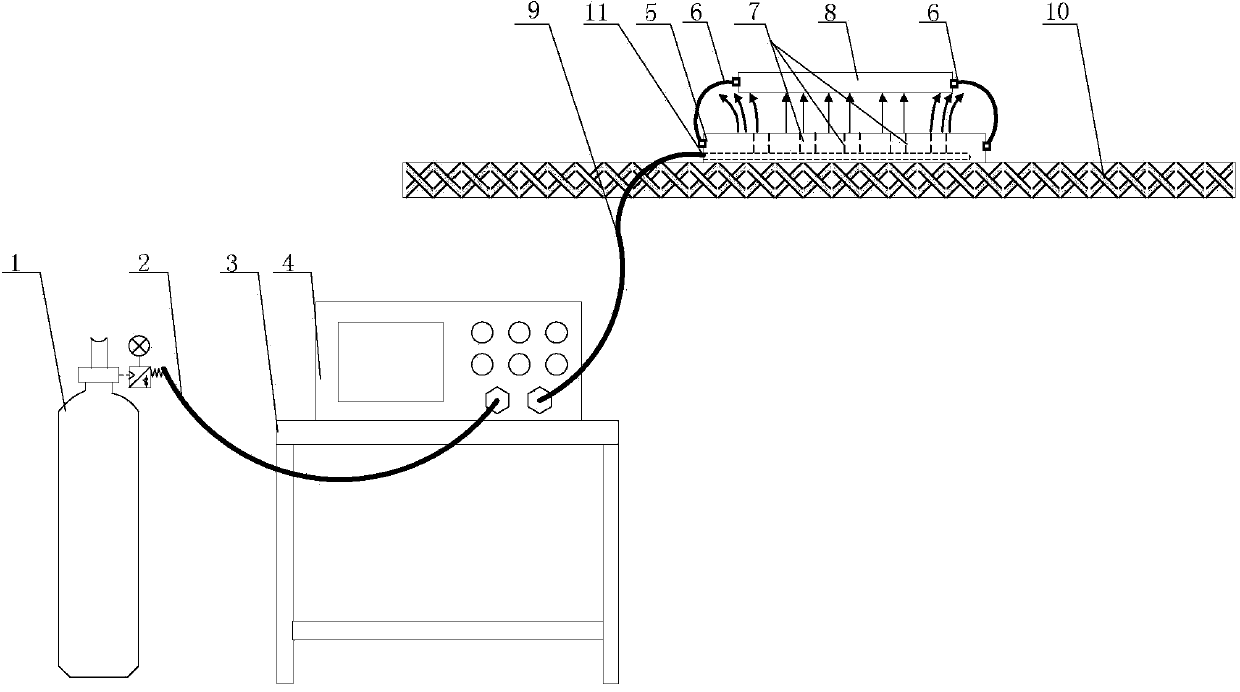

[0071] The stable output pressure of the air source is 10MPa, and the precision of the pressure controller: 0.01MPa.

[0072] The vertical load F required by a tire test Z0 is 4000N, select 16 vent holes covered by the suspension pallet, and the radius of the vent hole is 8mm, then the total area of the vent holes covered by the suspension pallet is S 托板出气 =16×πr 2 =32.15cm 2

[0073] to hold up F Z0 = Vertical load of 4000N, according to the total area S of air outlet holes under the suspension pallet 托板出气 and sub-high pressure gas pressure p 2 And the tire vertical load F required by the test Z0 Relationship exists between: S 托板出气 ·p 2 >F z0 , then there is p 2 >1.24MPa, therefore, it is necessary to adjust the pressure controller so that the air pressure of the sub-high pressure air duct meets p 2 >1.24MPa.

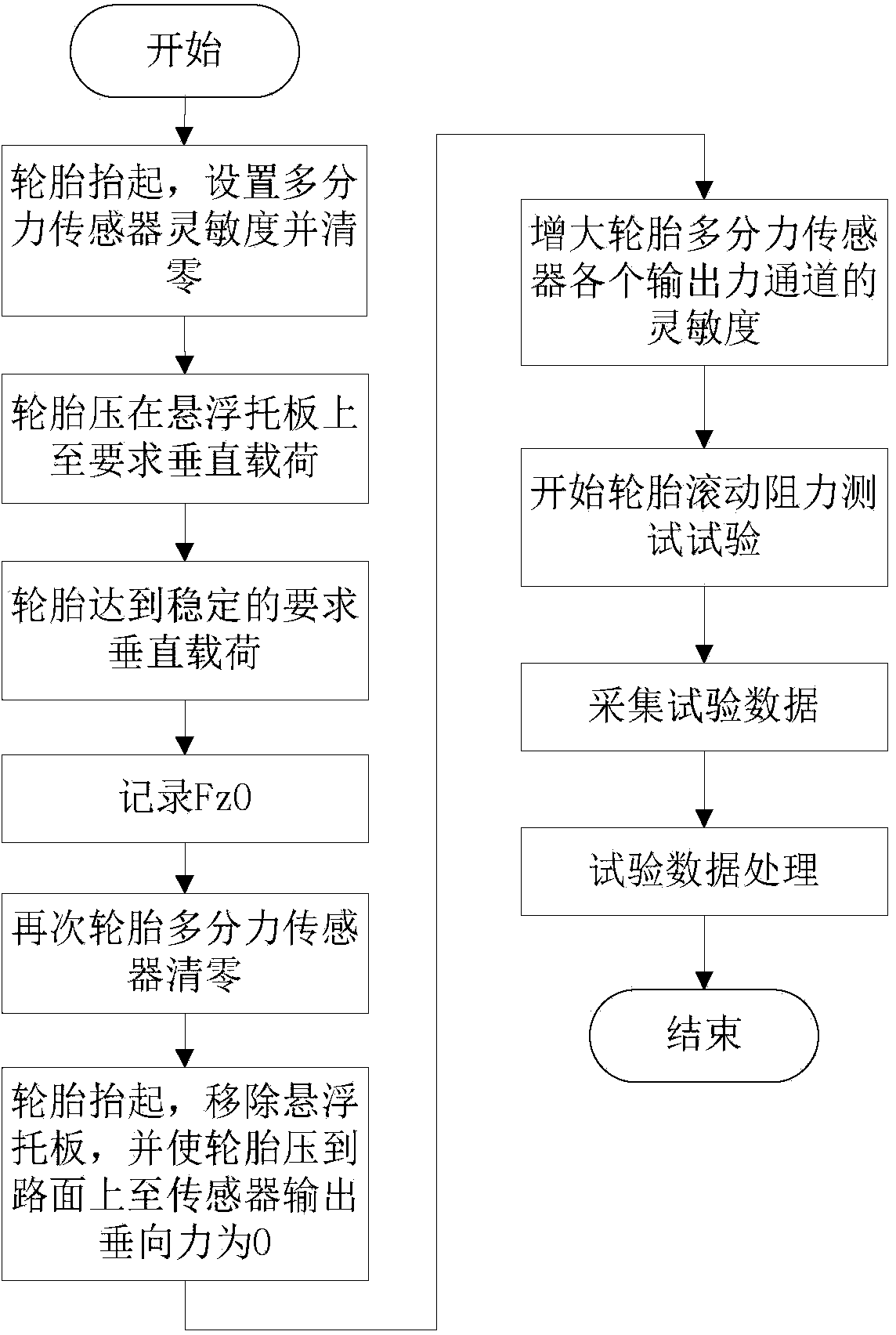

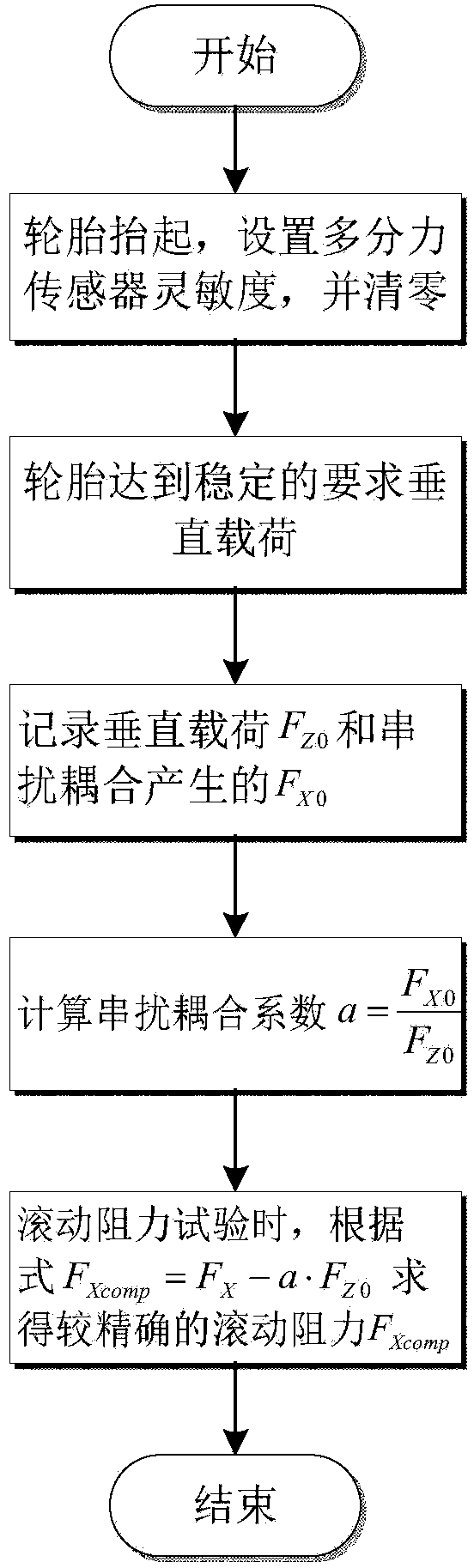

[0074] The steps of the precise measurement method for tire rolling resistance are as follows:

[0075] Step 1: Set the sensitivity of each output force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com